Oil-impregnated bearing and its fixing structure for oil-impregnated bearing

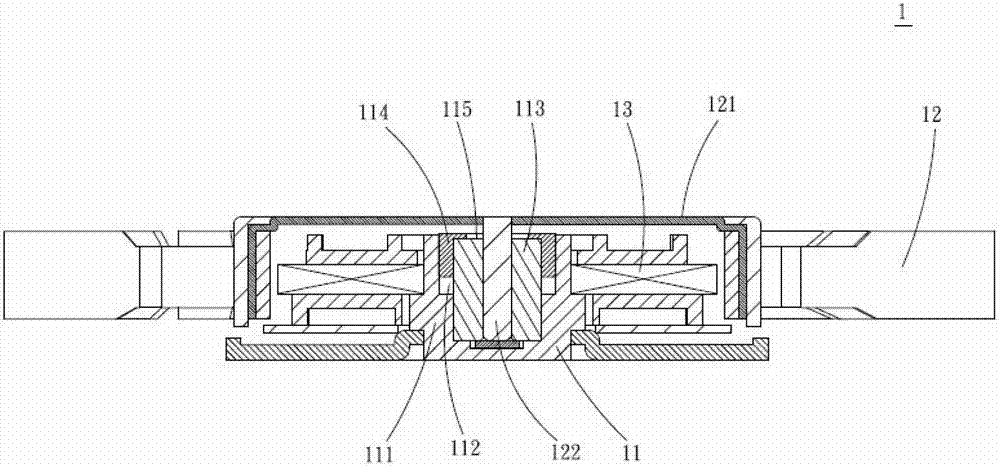

A fixed structure and bearing technology, applied in the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of reduced support force, abnormal noise, shaking and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

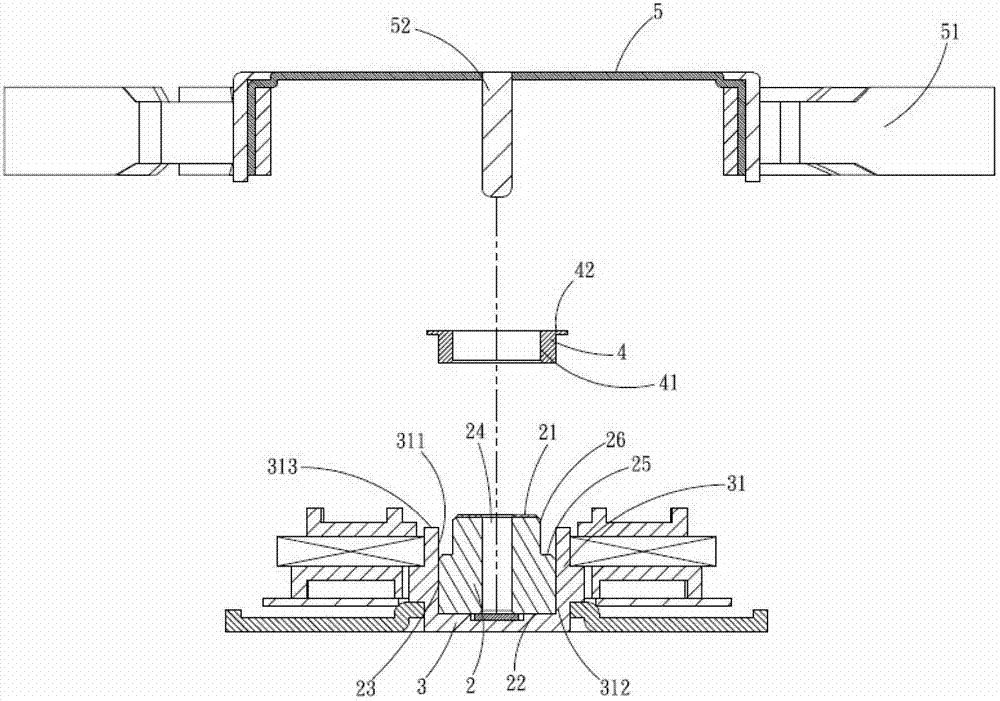

[0056] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

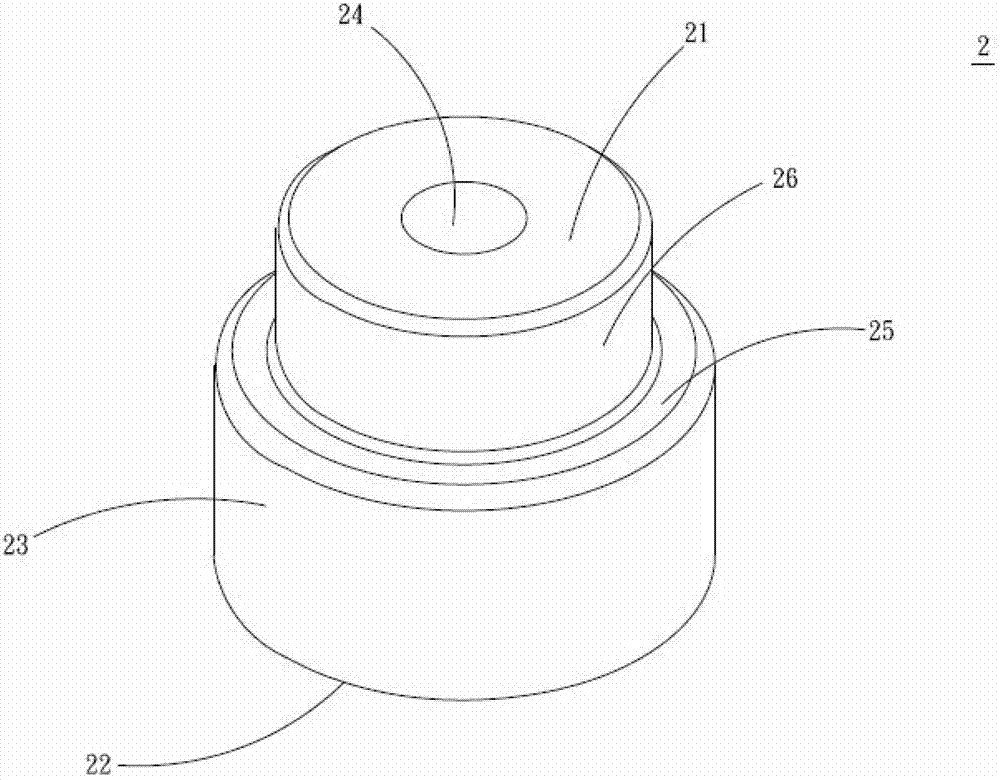

[0057] see figure 2 As shown, it is a three-dimensional schematic view of the first preferred embodiment of the oil-impregnated bearing of the present invention. The oil-impregnated bearing includes a bearing body 2, the bearing body 2 mainly has a top 21 and a bottom 22, and the top 21 and the bottom 22 form a There is a side 23 and a shaft hole 24, the side 23 is formed on the outer side of the bearing body 2, the shaft hole 24 is formed at the center of the bearing body 2, and the side 23 is formed by extending universally towards the shaft hole 24 There is a receiving portion 25, and an abutting portion 26 is formed between the receiving portion 25 and the top 21, and the width of the receiving portion 25 is smaller than the width of the bottom 22, and the length of the abutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com