Fireproof door frame capable of being simply and easily assembled

A door frame and simple technology, applied in the field of fire doors, can solve the problems of low strength, troublesome process, inconvenient connection of other components, etc., and achieve the effects of low cost, low operation difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

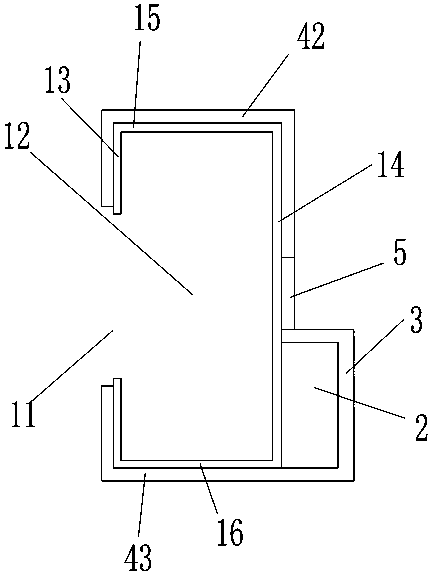

Embodiment 1

[0034] A fire-resistant door frame that can be easily assembled, including a door frame base and a door panel step arranged on the door frame base; Frame 1, a base sleeve set on the steel inner frame 1 and adapted to the outer contour of the steel inner frame 1; the steel inner frame includes buckle edges 13 facing the side of the wall and located on both sides of the notch, The seat edge 14 facing the side of the door leaf and parallel to the buckle edge, and the outer edge 15 and the inner surface edge 16 vertically connecting the buckle edge and the seat edge; The step cover 3 arranged on the fireproof block; the position corresponding to the fireproof block on the base cover is provided with a vacant section for making the fireproof block directly attached to the surface of the seat edge, and the surface of the fireproof block attached to the surface of the seat edge is the connecting surface , the step cover includes a three-piece connected cover edge on the three surface...

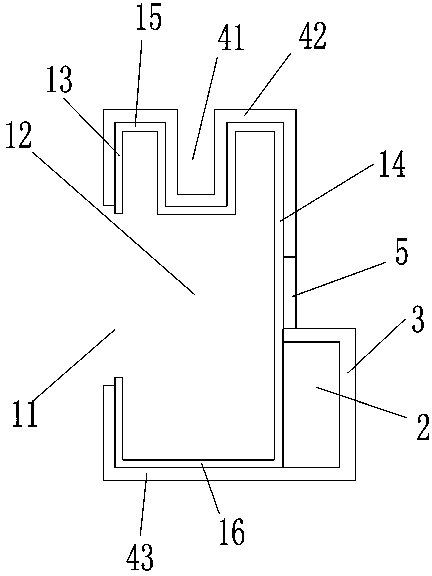

Embodiment 2

[0038] The difference from the above-mentioned embodiment is that there is a concave groove formed on the outer edge, and the corresponding groove position on the base cover is concavely formed to fit the groove and can be inserted into the groove to cover the wall of the groove. It is used to clamp the door pocket bayonet 41 of the door pocket. A decorative layer is covered on the outer surface of the base cover and the step cover, and 1-3 card slots are arranged on the outer edge.

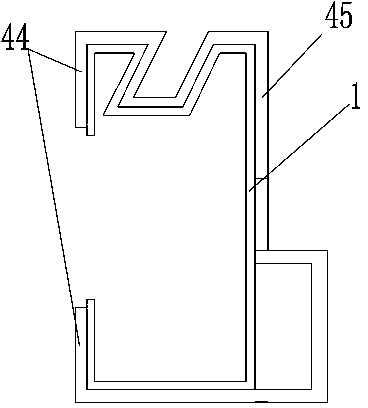

Embodiment 3

[0040] The difference from the above embodiment is that the card slot is a square card slot, and the bayonet of the door pocket is a square bayonet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com