Glass substrate taking and placing device

一种玻璃基板、取放装置的技术,应用在运输和包装、炉、电荷操纵等方向,能够解决晃动气流、增加制造成本、玻璃基板摆放精度低等问题,达到减少破损、减少制造成本、降低飘移的风险的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

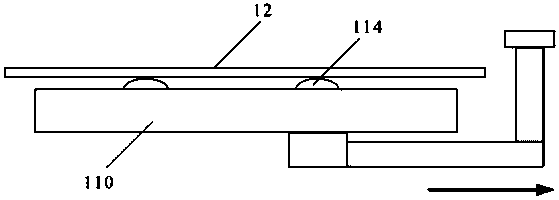

[0036] Referring to the drawings, wherein like reference numerals represent like components, the principles of the present invention are exemplified when implemented in a suitable computing environment. The following description is based on illustrated specific embodiments of the invention, which should not be construed as limiting other specific embodiments of the invention not described in detail herein.

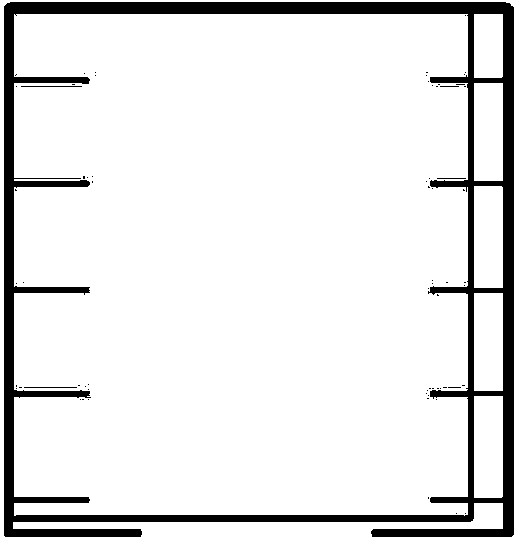

[0037] Please refer to figure 2 , figure 2 A schematic diagram of a pick-and-place device for a glass substrate provided in an embodiment of the present invention, wherein the pick-and-place device for a glass substrate includes:

[0038] A frame 10 and a bearing part 11 arranged on the frame 10;

[0039] The bearing part 11 includes: a bearing bracket 110, a first stopper 111 fixedly arranged on the bearing bracket 110, and a second stopper 112 movably arranged on the bearing bracket 110; wherein, the first The total number of stoppers 111 and the second stoppers 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com