Throttle Control Method of Centrifugal Chiller

A water chiller, throttling control technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of unstable operation of the unit, fluctuation of liquid level display value, low exhaust superheat, etc., to save liquid position sensor or temperature sensor, improving reliability and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

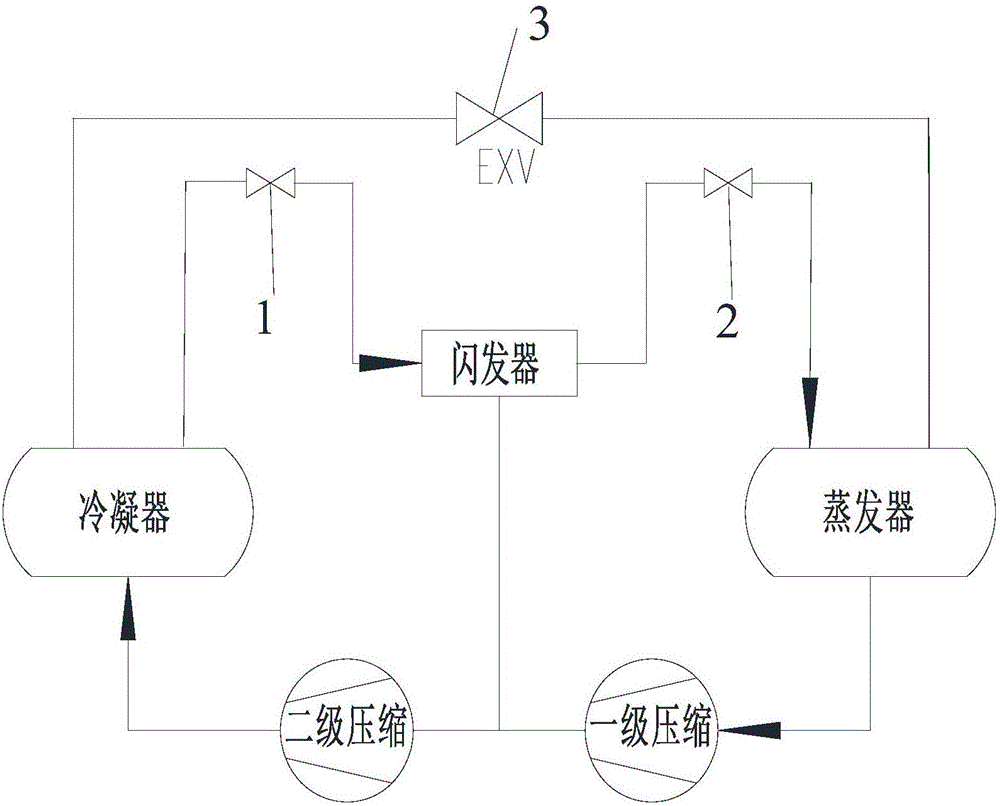

[0018] Such as figure 1 As shown, the main throttling circuit of the centrifugal chiller is the throttling of the primary orifice plate 1 and the secondary orifice plate 2, and the auxiliary throttling circuit is the throttling electronic expansion valve 3.

[0019] In the throttling control design, the calculation of throttling components (first-stage orifice plate 1, second-stage orifice plate 2 and electronic expansion valve 3) is generally based on the nominal full load, while the first-stage orifice plate 1 and the second-stage orifice There is no significant change in the flow rate of refrigerant circulating through plate 2 under partial load, so the throttling electronic expansion valve 3 on the auxiliary throttling circuit from the condenser to the evaporator is very important to adjust under partial load.

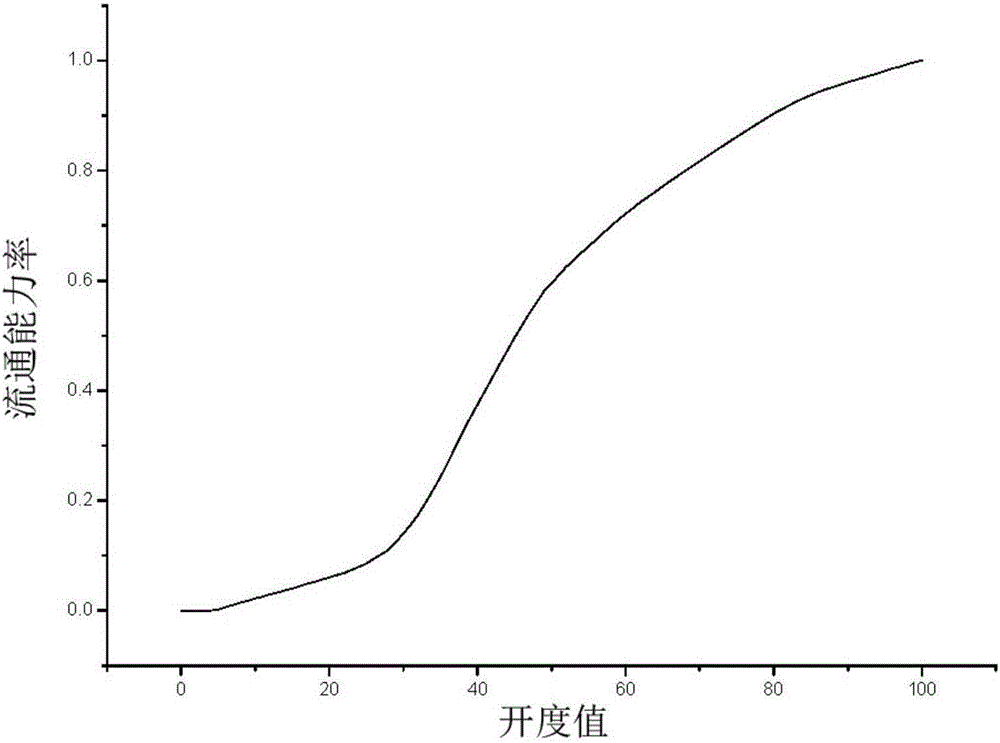

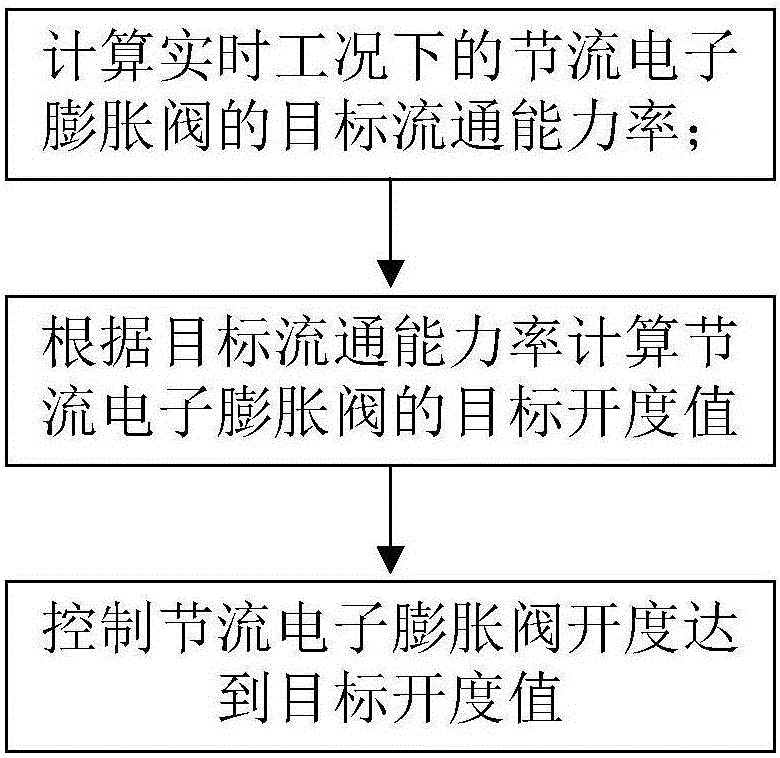

[0020] combine image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com