Water film desulfurization deduster

A technology of desulfurization dust collector and water film, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, and use of liquid separation agent, etc., can solve the problems that flue gas affects the dust removal effect, so as to improve the dust removal effect, increase the number and degree of impact, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0015] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

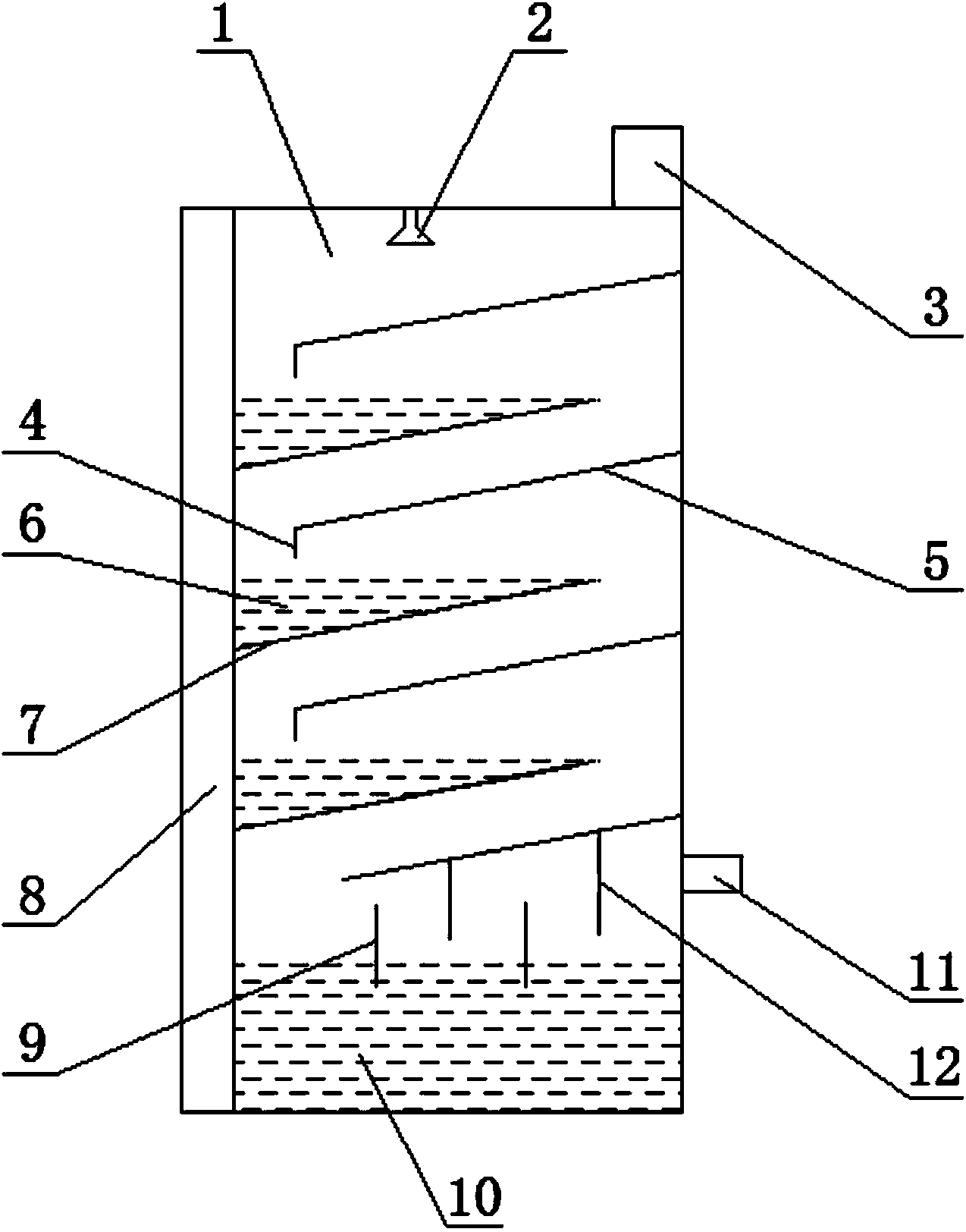

[0016] Such as figure 1 As shown, a water film desulfurization and dust collector according to a specific embodiment of the present invention includes: a tower body 1, a spray pipe 2, an air outlet pipe 3, an air guide baffle 5, a water storage baffle 7, and an upper baffle 12 , the lower baffle plate 9 and the drain pipe 8, the lower end of the tower body 1 inner chamber is provided with a water storage tank 10, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com