Mechanically controllable valve train

A transmission mechanism and mechanical control technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of unsatisfactory operating characteristics of the engine, failure to re-establish valve lift, and failure to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

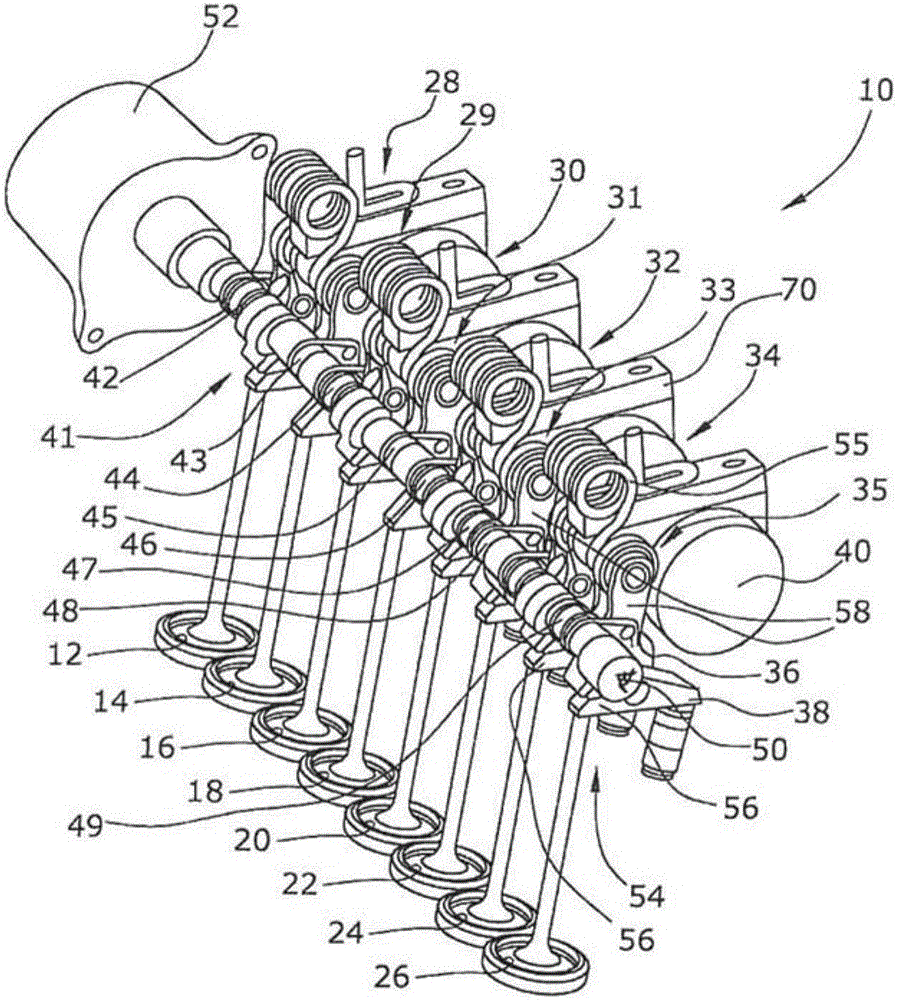

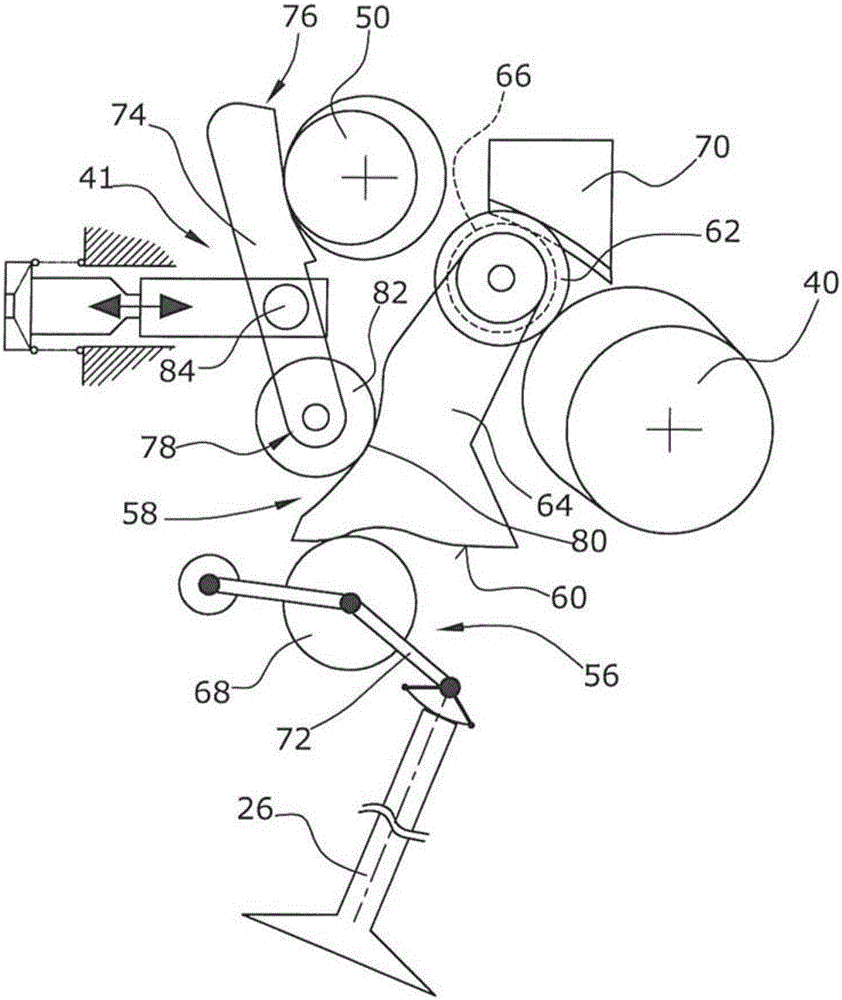

[0012] figure 1 An embodiment of the valve train 10 according to the invention is shown, comprising a plurality of gas exchange valves 12 , 14 , 16 , 18 , 20 , 22 , 24 and 26 arranged in a row. In the illustrated case, every two intake valves are assigned to a cylinder of the internal combustion engine. The mechanically controllable valve train 10 has four transmission devices 28, 29, 30, 31, 32, 33 and 34, 35 in the present embodiment, for which two gas exchange valves 12, 14 are assigned respectively; 16, 18; 20, 22; 24, 26. Here, the transport devices 28 , 29 , 30 , 31 , 32 , 33 and 34 , 35 are mounted in a known manner on the cylinder head by means of bearing devices. exist figure 1 The support devices 36 , 38 for supporting the rocker 56 of the transport device 35 are only shown by way of example. In addition, the transmission devices 28 , 29 , 30 , 31 , 32 , 33 and 34 , 35 are operatively connected to the camshaft 40 in a known manner. In addition, each transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com