Brake disc for a vehicle

A technology of brake discs and disc brakes, applied in the direction of brake discs, brake types, brake components, etc., can solve problems such as large structural space, and achieve the effect of reducing structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

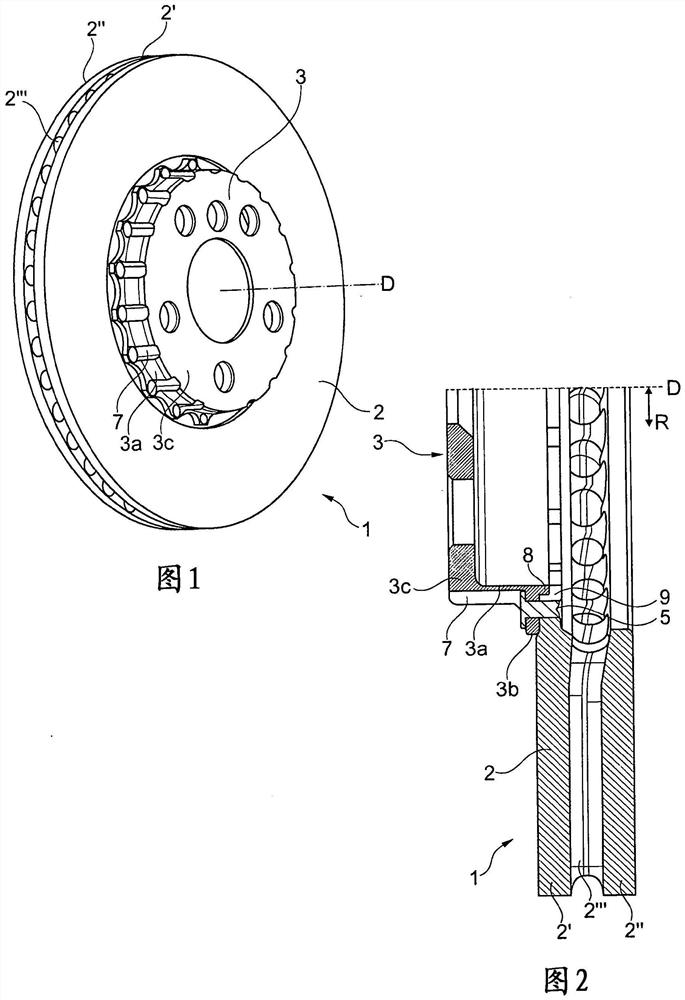

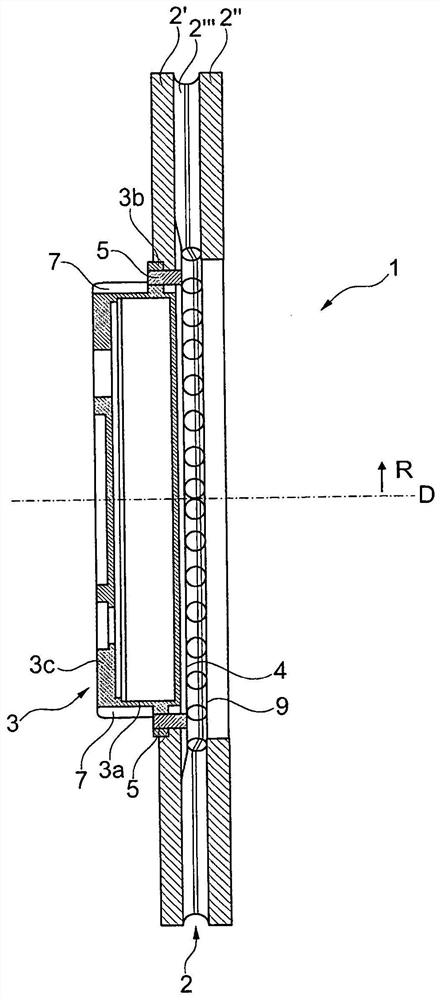

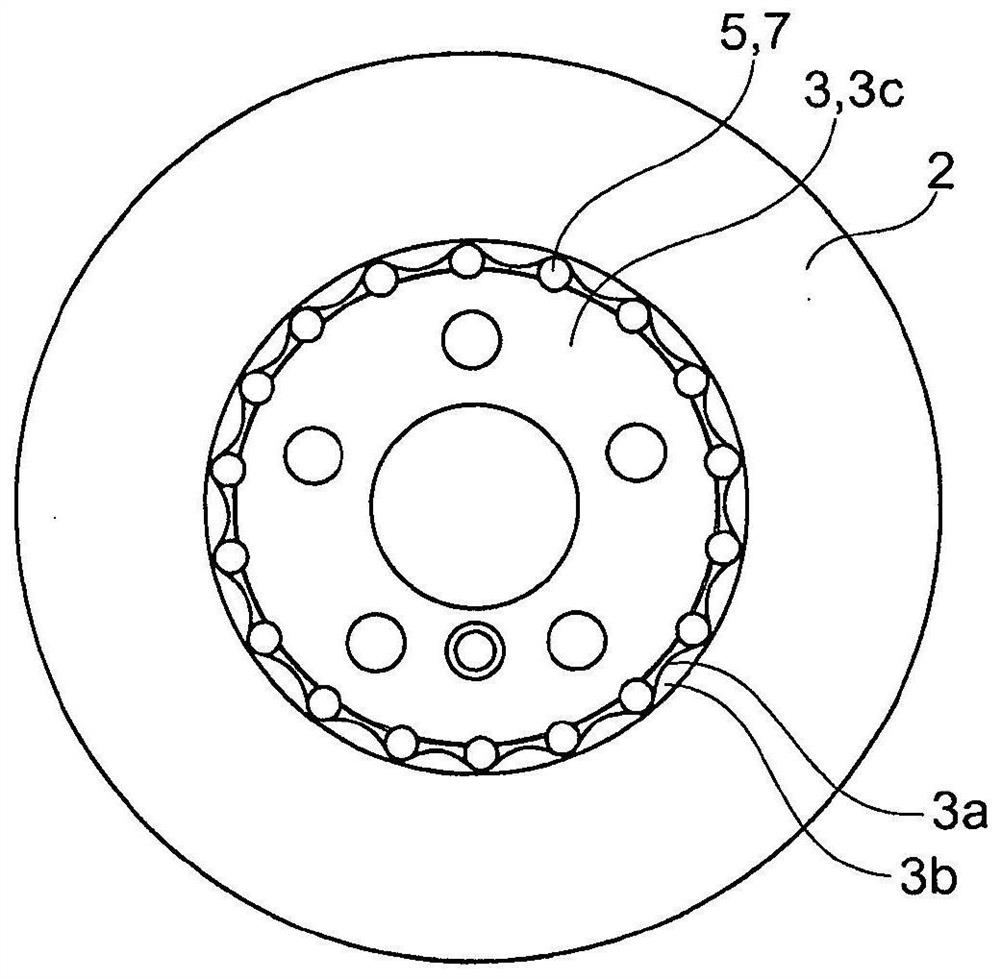

[0017] The brake disc 1 shown in the figure comprises a brake disc fixing drum 3 and a friction ring 2, and the brake disc is (as usual) provided for fitting on a hub not shown, so that as the hub is During operation, it rotates about the axis of rotation D. The one-piece, internally cooled friction ring 2 made of gray cast iron comprises two friction disks 2 ′, 2 ″ and a cooling ring between the two friction disks and connecting them to each other. Air guide 2"'. The annular friction disc 2 ′, viewed in the axial direction, ie, viewed in the direction of the axis of rotation D, which is closer to the brake disc fixing drum 3 , viewed in the radial direction R (with respect to the axis of rotation D), is smaller by means of so-called fastening projections 9 than The other friction disc 2 ″, which is further away from the brake disc drum 3 in the axial direction, extends further towards the axis of rotation D by a certain (small) amount.

[0018] Between the mentioned fasteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com