A double-glass photovoltaic module structure and packaging method

A module structure, double-glass photovoltaic technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems that the battery does not have durability, UV resistance, low output power, etc., so as to reduce surface chromatic aberration defects and improve power output. , Improve the effect of reflected light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

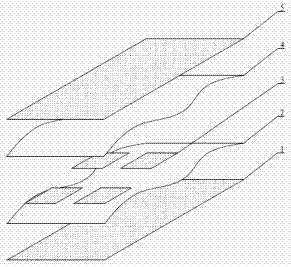

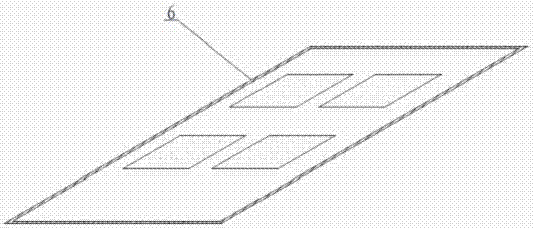

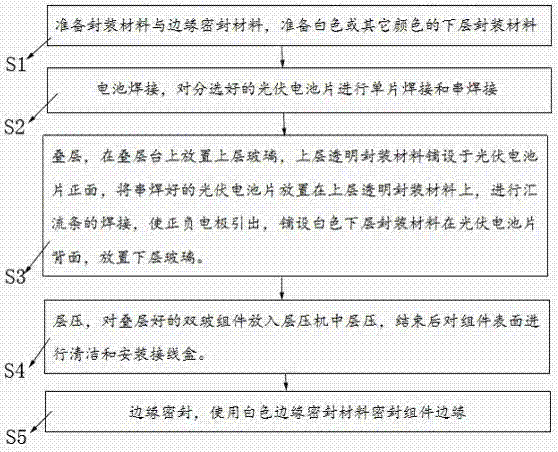

[0026] Such as figure 1 As shown, a double-glass photovoltaic module structure includes an upper glass 5, an upper packaging material 4, a photovoltaic cell 3, a lower packaging material 2 and a lower glass 1, the upper packaging material 4 is laid on the front of the photovoltaic cell 3, and the upper packaging material 4 is a transparent packaging material, and the lower packaging material 2 is a non-transparent packaging material. The formula of the non-transparent packaging material is mainly 90% vinyl acetate, 3% ultraviolet absorber, 3% antioxidant and 3% light stabilizer. It is made of opaque pigment, and 0.5-2g of opaque pigment titanium dioxide is added per square meter of packaging material to make a white non-transparent packaging material, and the lower layer of white packaging material 2 is laid on the back of the photovoltaic cell 3 .

[0027] Since the white non-transparent packaging material is laid on the back of the photovoltaic cell, it can improve the absor...

Embodiment 2

[0029] All the other are the same as Example 1, except that the non-transparent encapsulation material formula is mainly 85% vinyl acetate, 5% UV absorber, 5% antioxidant and 4% light stabilizer adding opaque pigment It is made by adding 0.5-2g of opaque pigment titanium dioxide per square meter of packaging material to make a white non-transparent packaging material.

Embodiment 3

[0031] All the other are the same as Example 1, except that the non-transparent encapsulation material formula is mainly 85% vinyl acetate, 5% UV absorber, 4% antioxidant and 5% light stabilizer adding opaque pigment It is made by adding 0.5-2g of opaque pigment titanium dioxide per square meter of packaging material to make a white non-transparent packaging material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com