On-production-line filament-arranging glass core-cutting lamp tube sealing process and dedicated sealing machine

A sealing machine and lamp technology, which is applied in the direction of electric tube/lamp closing, etc., can solve the problems of thermal stress, cold explosion, slow temperature rise, etc., and achieves the effect of eliminating the occurrence mechanism of cold explosion and solving the problem thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

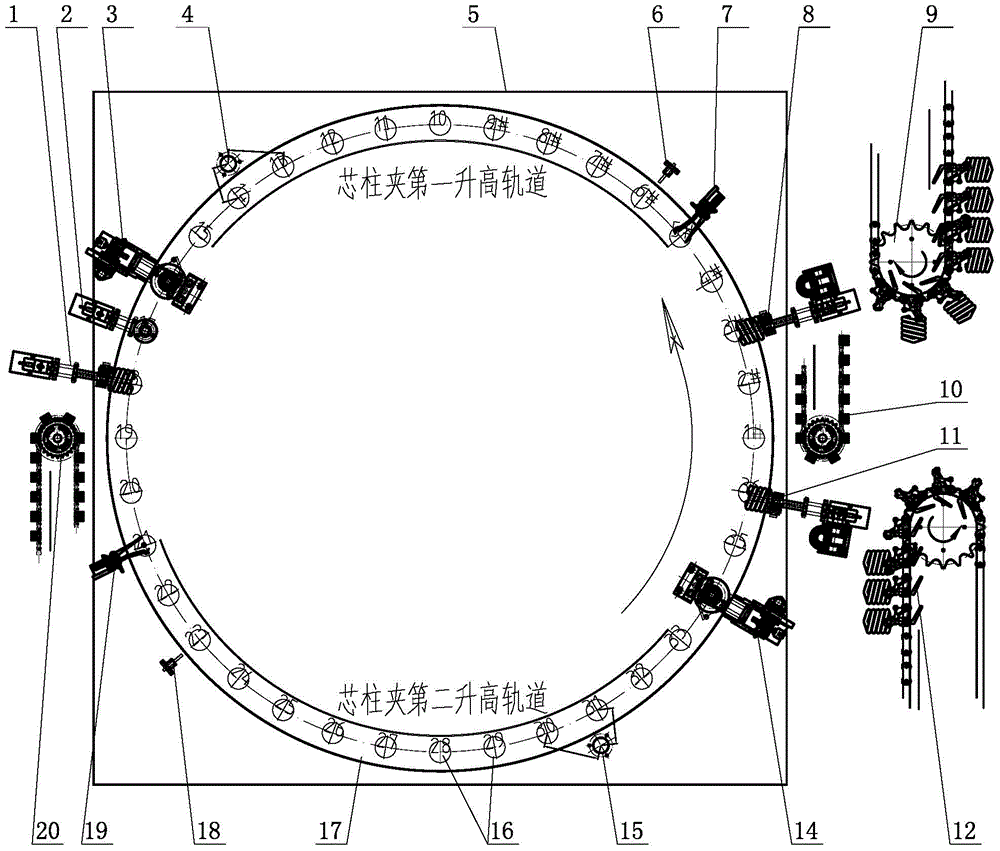

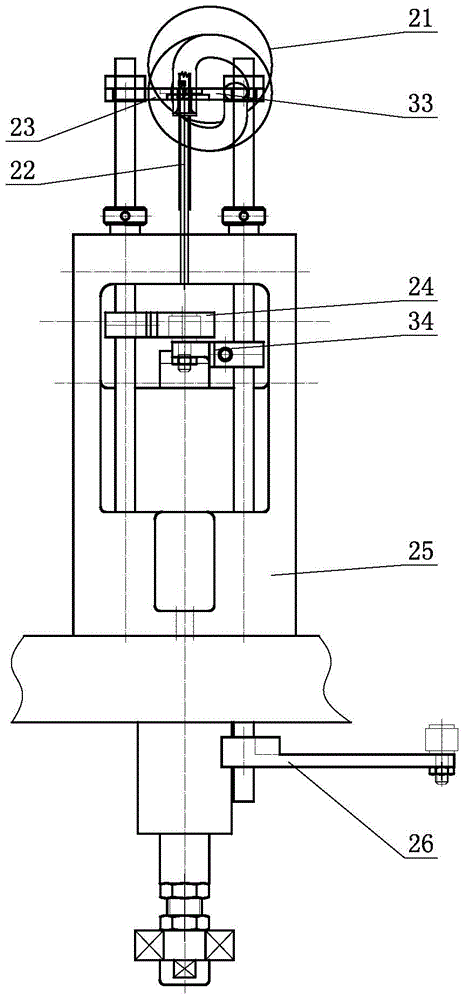

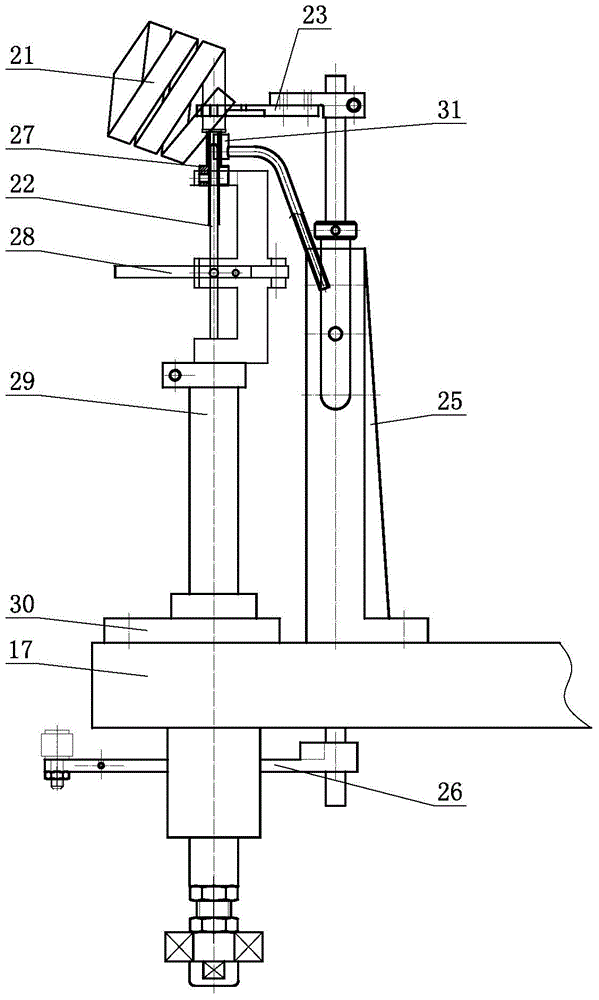

[0069] Taking a relatively specific fully automatic sealing machine designed based on the process concept of the present invention as an example, the sealing process of the present invention and the technical principle of the sealing machine for online wire trimming and cutting of glass cores will be further explained in conjunction with the accompanying drawings.

[0070] In this example, the rotary workbench 17 of the sealing machine is circular, and a plurality of stations corresponding to each process are arranged in turn along the circumference. The frame 5 rotates in one direction, so as to avoid repeated continuous sealing process.

[0071] The rotation of the worktable is usually realized by the frame, the worm gear box, and the center plate. The worm gear box is installed on the frame, and the worm gear box drives the center plate. The rotating platform is set on the center plate and rotates with the center plate. The prime mover of the worm gear box It can be a contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com