Energy-saving and anti-shake controller circuit of contactor

A contactor and anti-shake technology, applied in the direction of circuits, relays, electrical components, etc., can solve the problems of disrupting production continuity, waste of holding power, and lack of complete equipment selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

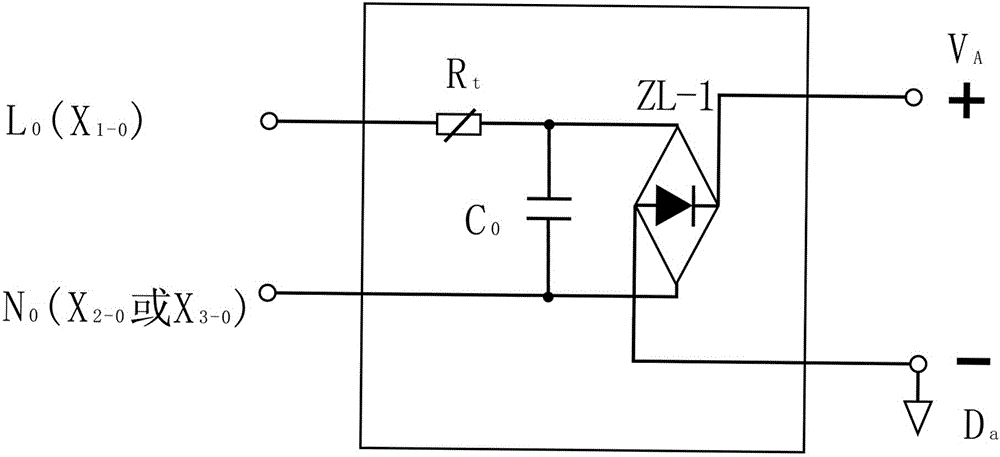

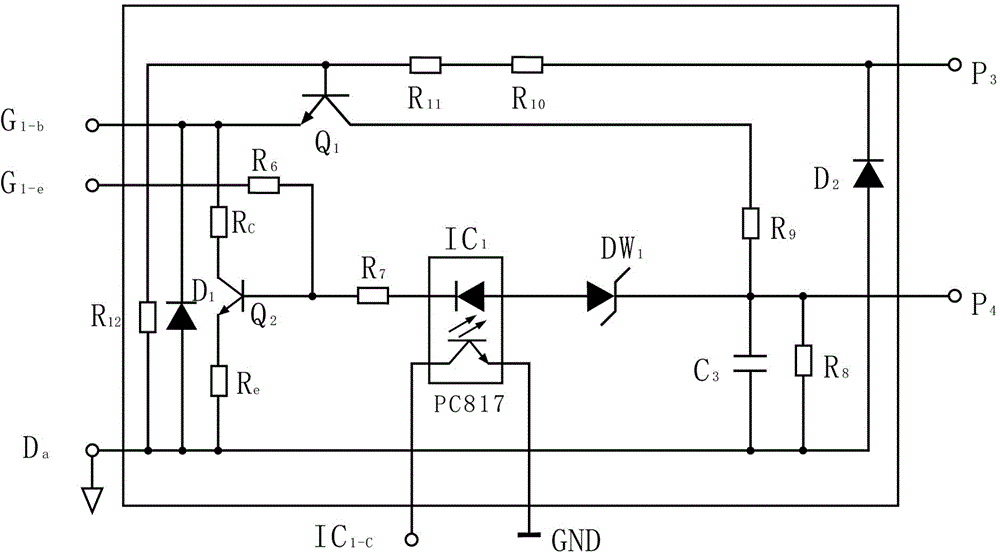

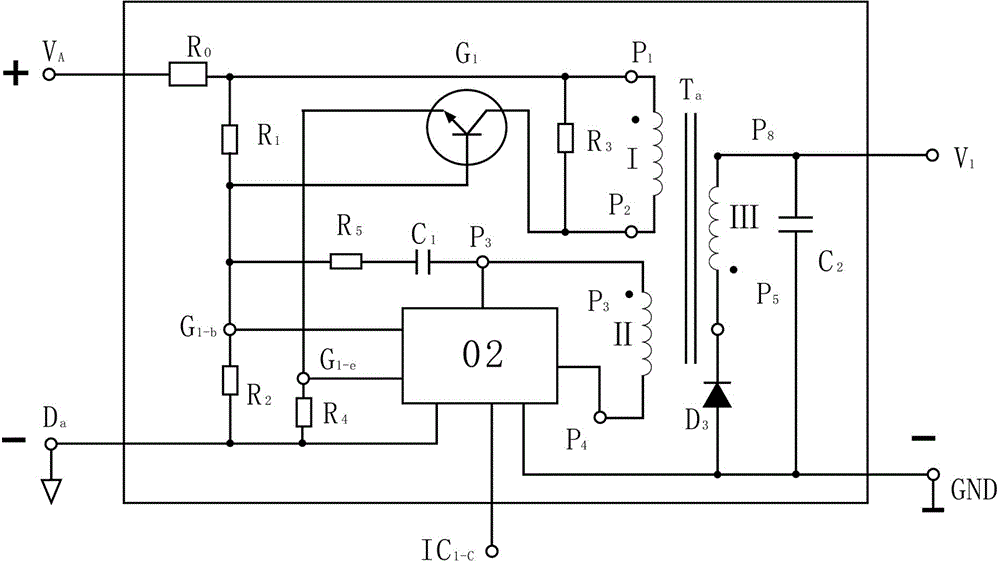

[0036] like Figure 14 As shown, a contactor energy-saving and anti-shaking controller circuit includes an electronic energy-saving module circuit 08 for contactors and an electronic energy-saving module full-voltage automatic time-sharing and batch restart control circuit 013; Figure 8 As shown, the electronic energy-saving module circuit 08 for the contactor includes: a full-voltage AC (DC)-DC conversion circuit 04 with a short-circuit protection function, a full-voltage "intelligent closing operation" and a low-voltage holding circuit 06, and a voltage inverse time limit pulse Wide time generating circuit 07; such as Figure 4 As shown, the full-voltage AC (DC)-DC conversion circuit 04 with short-circuit protection function is composed of full-voltage rectification circuit 01 with short-circuit protection function and pulse width modulation (PWM) DC-DC conversion with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com