Device for testing buffer performance of magnetorheological elastomer

A magnetorheological elastomer and performance technology, which is applied in the direction of using a single impact force to test the strength of materials, etc., can solve the problems of easily causing accidents, the cushioning performance of magnetorheological elastomers cannot be guaranteed, and the safety hazards of buffers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

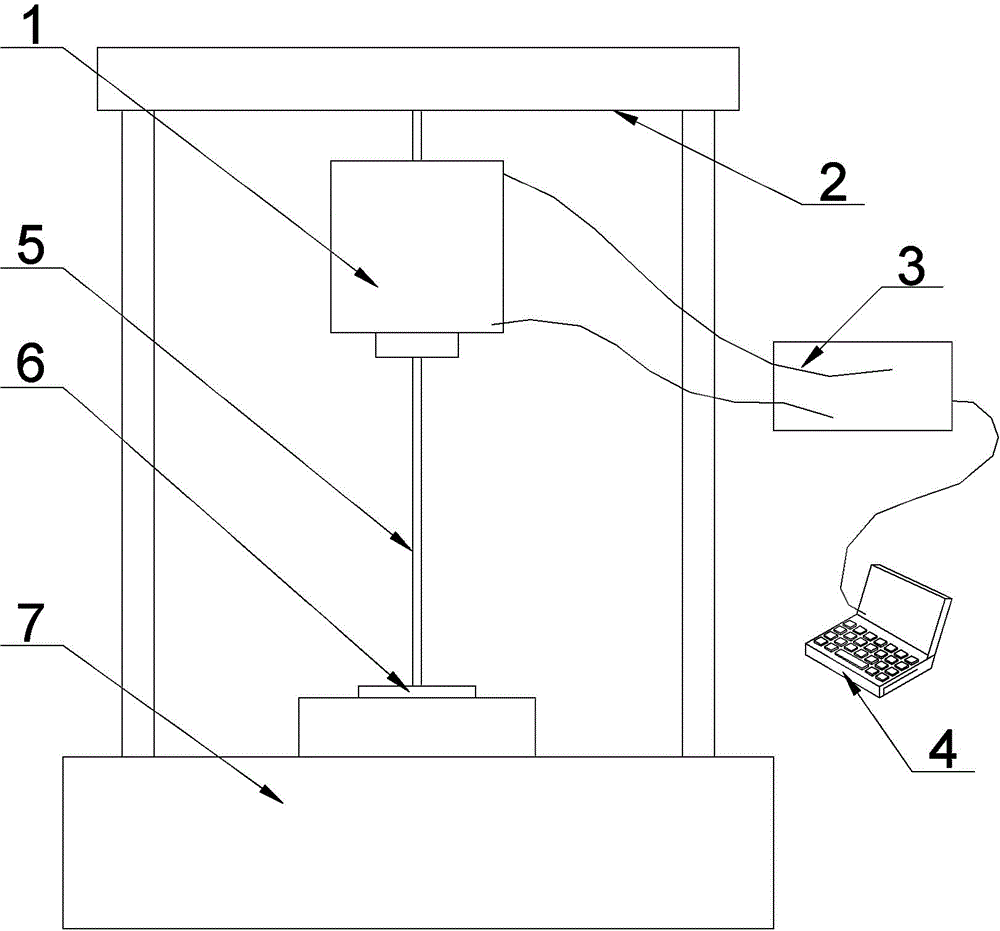

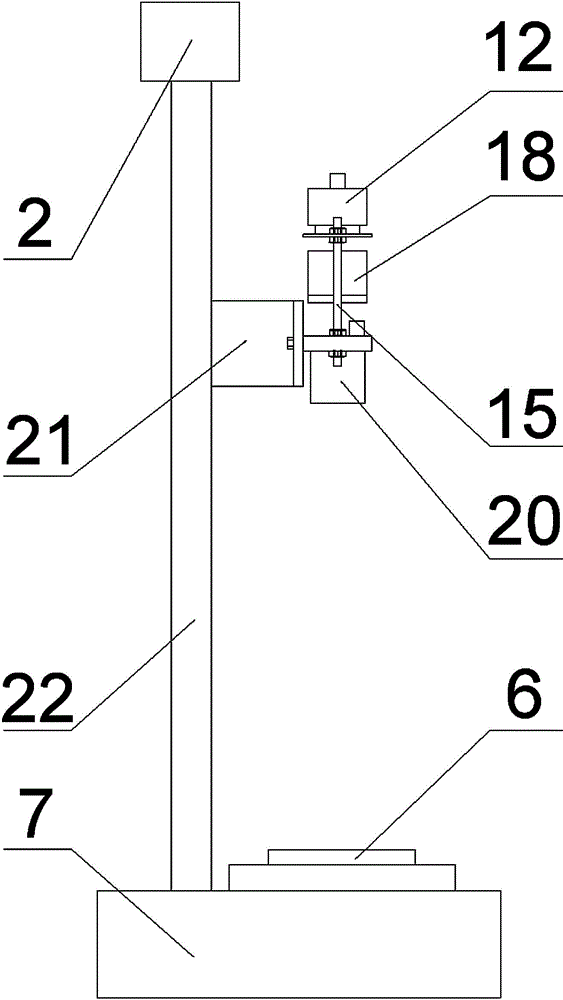

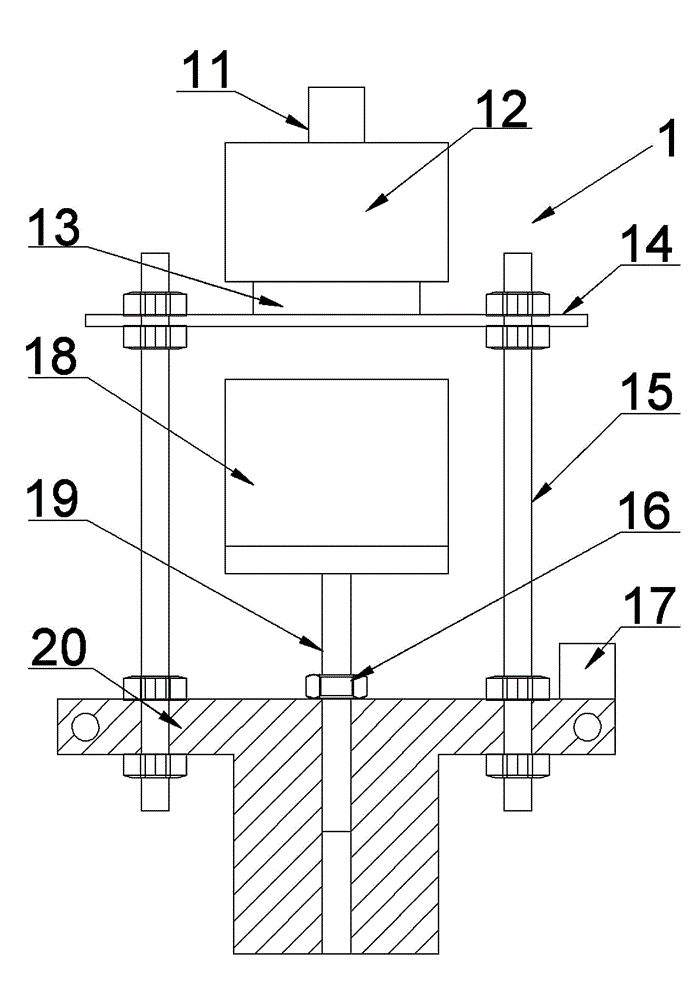

[0023] see Figure 1 to Figure 3 , is an embodiment of a device for testing the cushioning properties of magnetorheological elastomers, including a base 7, an upper beam 2, and at least two columns 22 connected to the base 7 and the upper beam 2. In this embodiment, the column The number is two, and the base is designed as a strip to reduce the footprint of the base. The upper and lower ends of the two columns are respectively connected to the upper beam and the base by bolts. A linear slide rail 5 is erected between the base 7 and the upper beam 2, the upper end of the linear slide rail 5 is fixedly connected to the upper beam 2, and the lower end of the linear slide rail 5 is fixedly connected to the base 7. In this embodiment, the straight line The upper and lower ends of the slide rail are fixedly connected to the upper beam and the middle end of the base by bolts respectively, so that the force bearing effect is better.

[0024] An impact movement frame 1 is slidably mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com