Real wall temperature testing system and manufacturing process of high-temperature heating surface tubes for thermal power units

A technology for heating surface tubes and thermal power units, which is applied in the field of temperature measurement systems, can solve the problems that the metal wall temperature cannot be truly measured, and the service life of the furnace wall material cannot be correctly evaluated, so as to achieve guiding significance and accurate life evaluation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

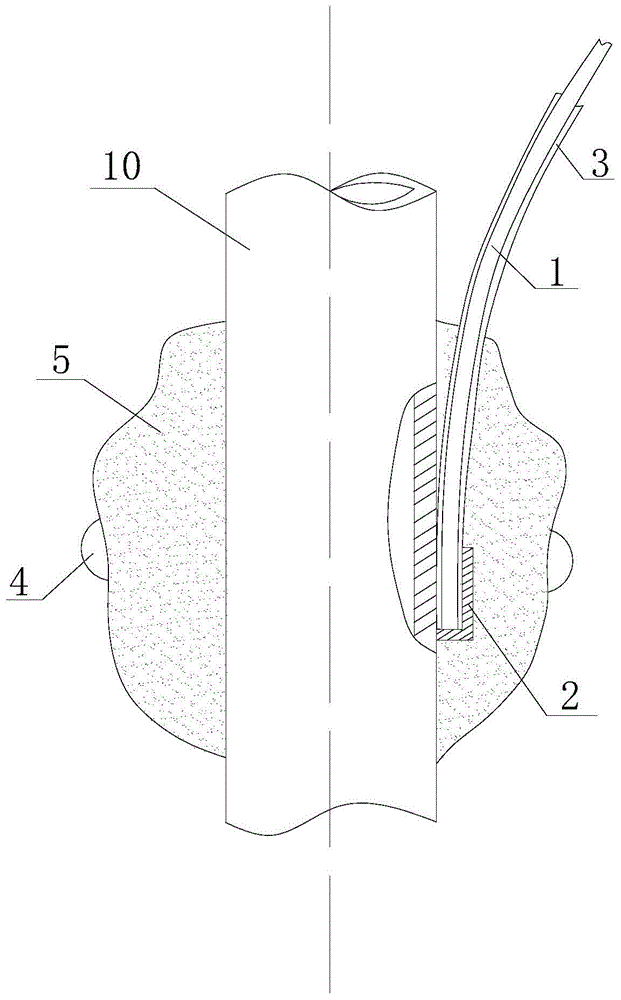

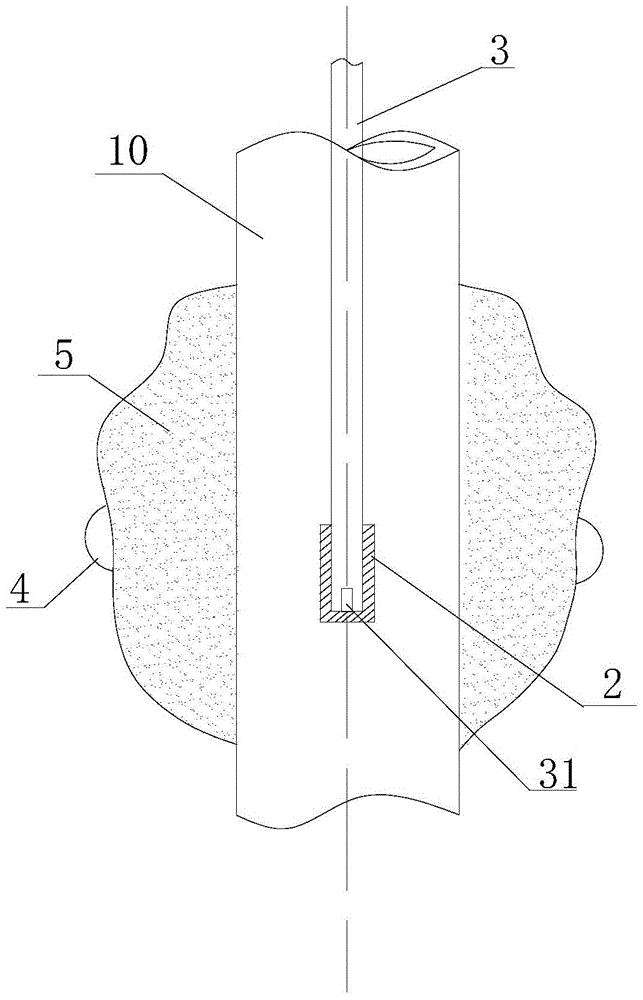

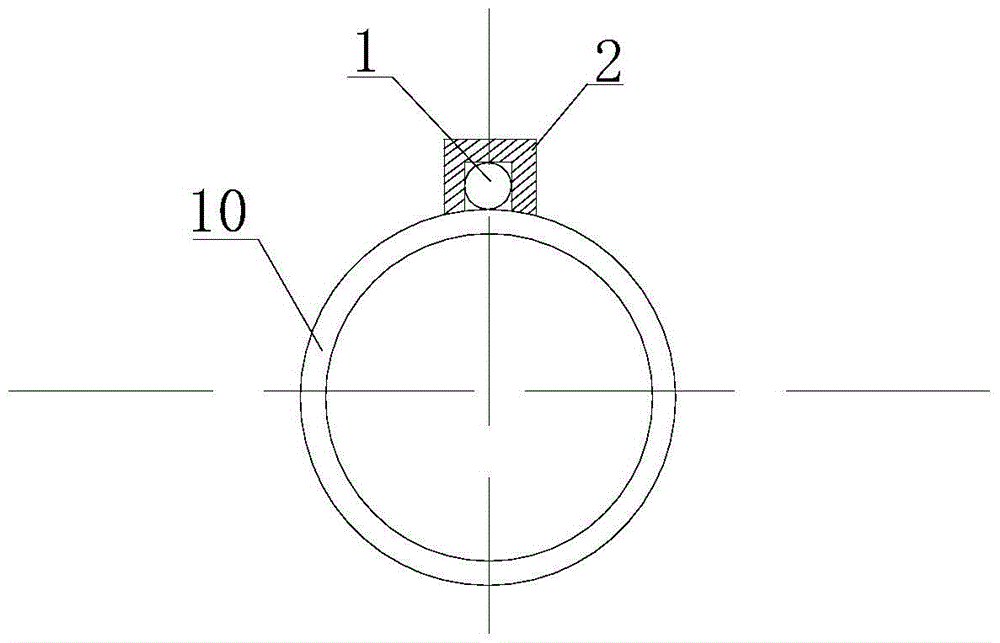

[0025] Such as Figure 1~3 The real wall temperature test system of the high-temperature heating surface tube of the thermal power unit shown mainly includes thermocouple 1, heat collector block 2, protective sleeve 3, hoop 4 and insulation material 5, etc. Among them, multiple thermocouples 1 can be set according to the measurement needs, and at the same time, the length of the thermocouples is also different according to the distance between the installation position and the roof of the furnace roof. For example, in a specific site, we choose 2 23m thermocouples, 6 20m thermocouples, 6 17m thermocouples, 4 14m thermocouples, 2 11m thermocouples, a total of 20 thermocouples for temperature measurement. The accompanying drawings of this embodiment provide one as an example. Specifically, the thermocouples 1 are welded on the corresponding tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com