A Method for Measuring the Fatigue Crack Growth Rate of Surface Strengthened Components

A technology of fatigue crack growth and crack growth rate, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, which can solve the problem of not being able to obtain experimental data, and achieve the effect of accurate life evaluation and experimental cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

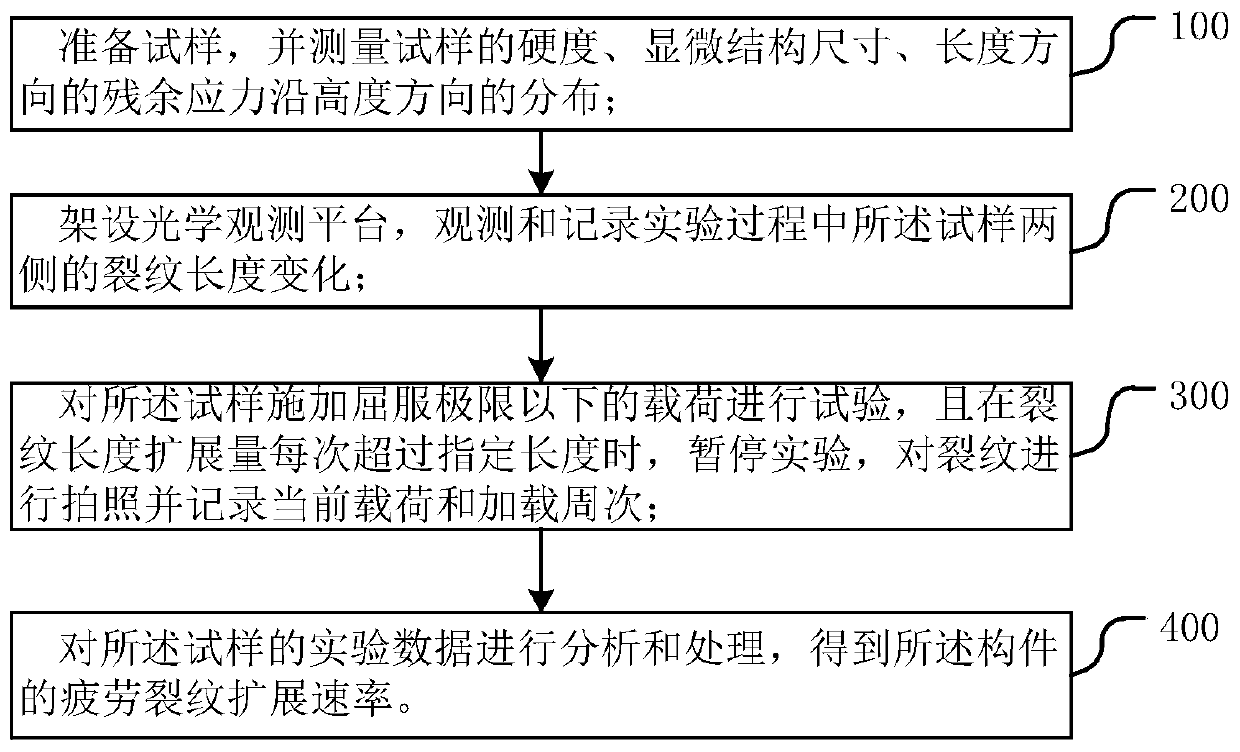

[0028] Such as figure 1 , 2 Shown, assay method of the present invention generally comprises the following steps:

[0029] Step 100, preparing the sample; and measuring the hardness of the sample, the size of the microstructure, the distribution of the residual stress in the length direction along the height direction, and the length of the prefabricated defect.

[0030] In this step, the sample is directly cut from the full-scale component, which needs to include the surface gradient strengthening layer, and the shape after cutting can be a rectangle. Then measure the length L, width W and height H of the sample, and determine the span length L of the sample 0 ; The height of the sample is at least 10 times the thickness of the reinforcement layer on the surface of the sample, so that the residual stress distribution of the sample is the same as that of the full-scale component. For the cylindrical member, its width W can be less than or equal to one-sixth of its diameter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com