A stepped self-sealing waste heat recovery system

A waste heat recovery system and self-sealing technology, applied in the field of flue gas waste heat recovery, can solve the problems of affecting the efficiency of waste heat power plants, reducing the taste of waste heat flue gas, and excessively large aspect ratio of the hot air hood. The effect of cooling air and improving the recovery rate of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

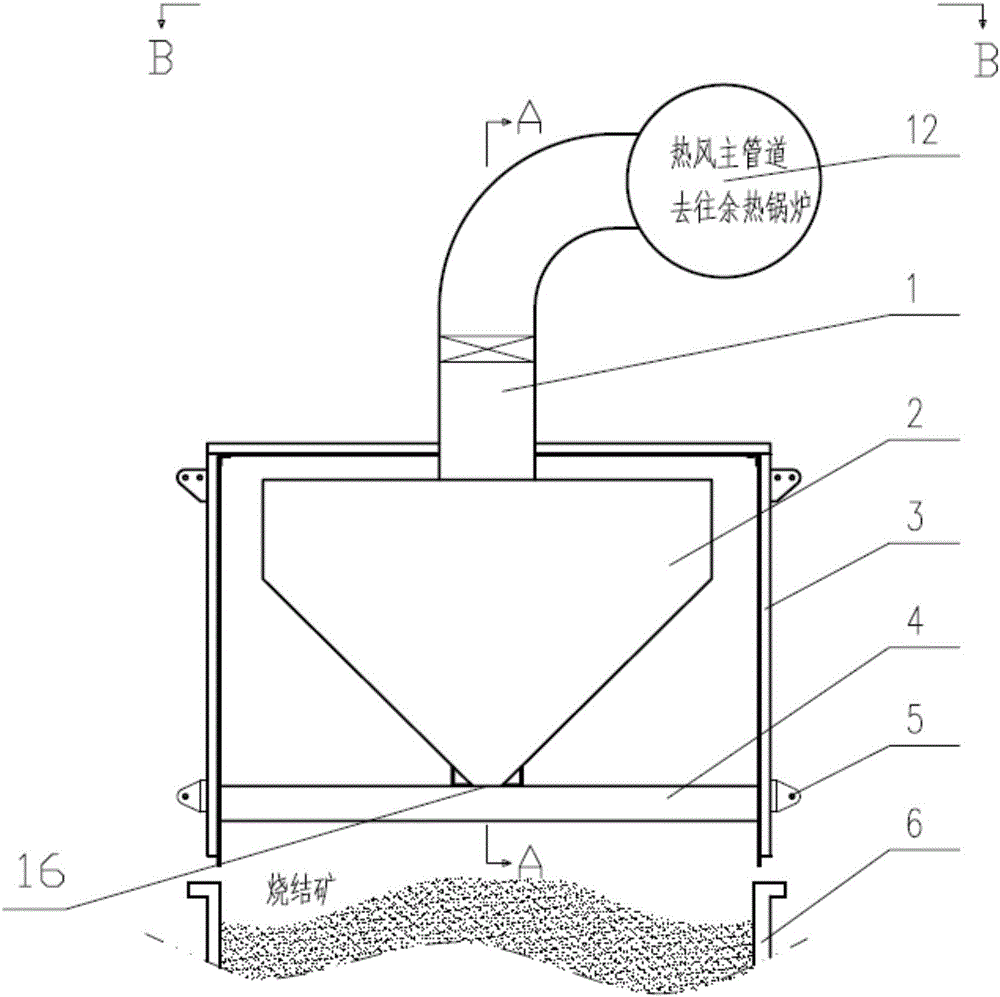

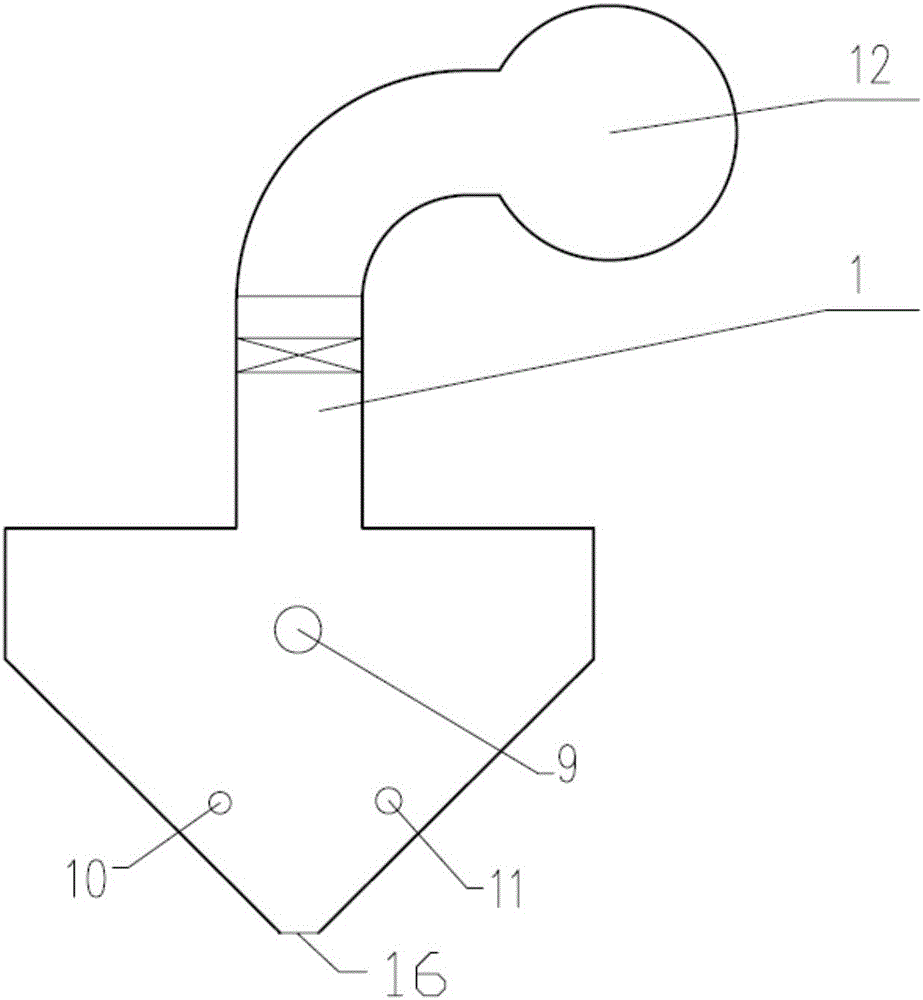

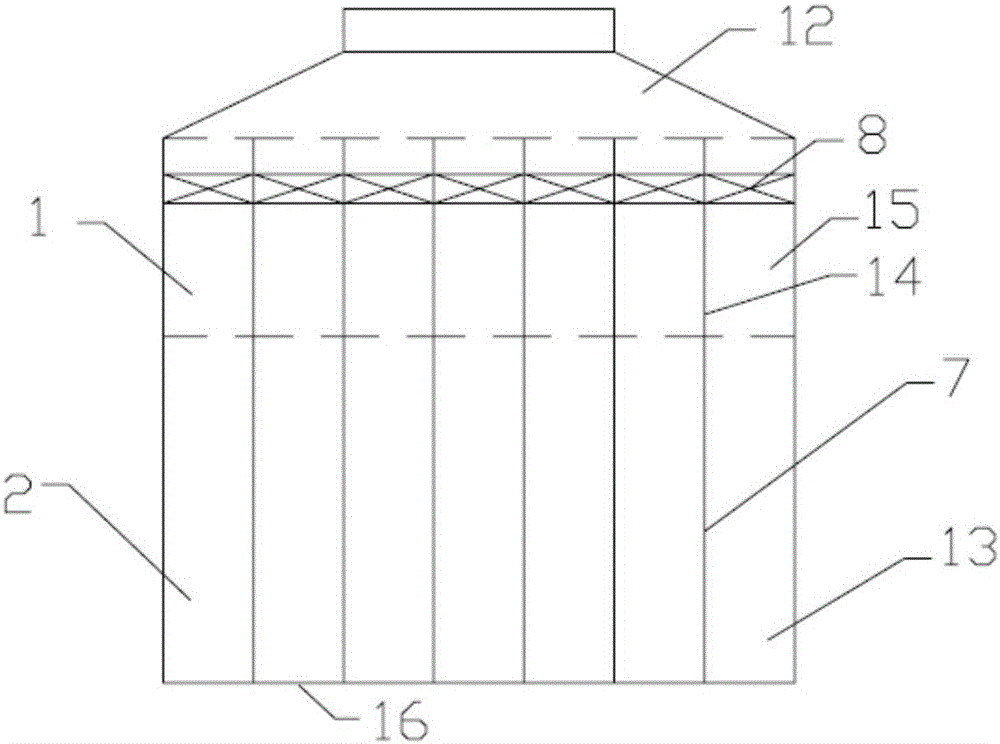

[0016] Such as figure 1 , figure 2 with image 3 As shown, the stepped self-sealing waste heat recovery system of this embodiment includes a hot blast cover 3 and a hot blast piping system 12. The hot blast piping system can be connected to the waste heat boiler, and the hot blast cover can cover the sintered ore of the sintering cooling trolley 6. There is also a built-in flue 2 inside the hot air hood, and a flue gas outlet 1 is arranged on the hot air hood. The built-in flue 2, the flue gas outlet 1 and the hot air piping system 12 are sequentially connected. For the long and narrow suction port 16 for extracting hot air, the built-in flue 2 is divided into several sub-built-in flues 13 by several flue partitions 7 along the length direction of the suction port, and the flue partition 7 is perpendicular to the length direction of the suction port 16 , the suction port is also divided into several sub-suction ports by the flue partition, and each sub-built-in flue has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com