Regional Gas Enhanced Drainage Method of Single Low Permeability Protruding Thick Coal Seam

A gas-permeable, thick coal seam technology, applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems such as the difficulty of drainage up to the standard and the difficulty of coal seam drilling construction, so as to increase the exposed area, improve the efficiency of gas drainage, Improve the effect of gas pre-pumping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

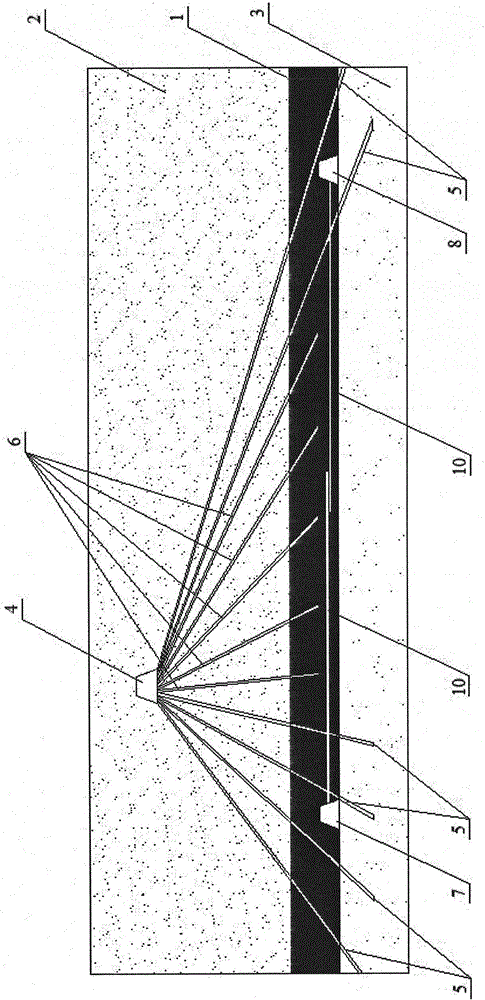

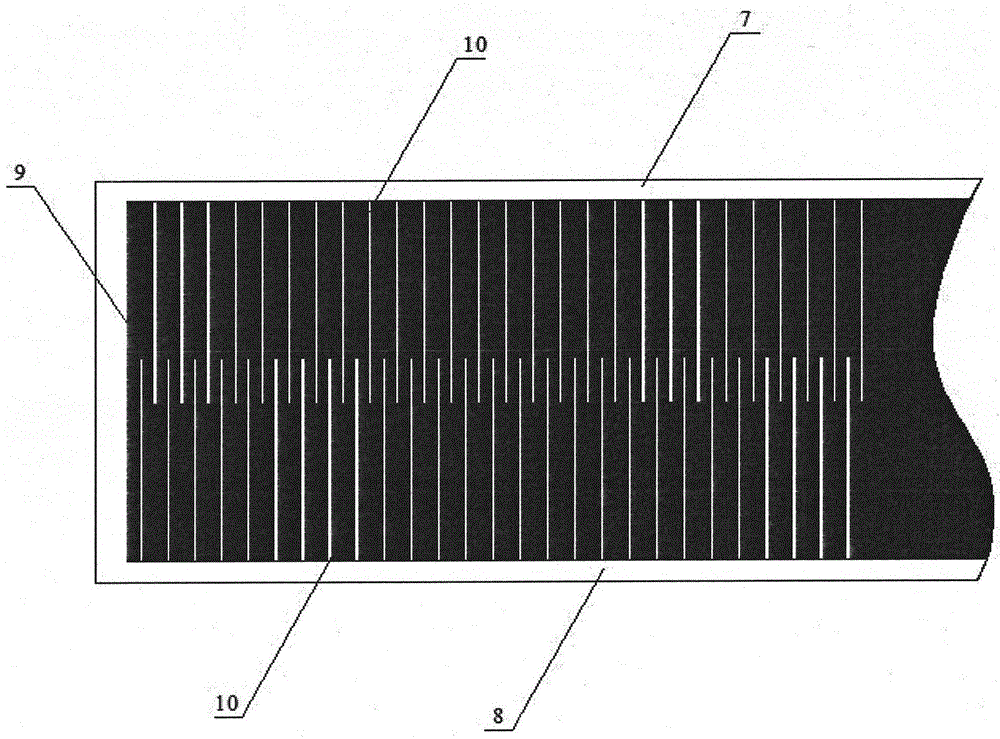

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] Figure 1-4 What is shown is a preferred embodiment of the regional gas enhanced drainage method for a single low-permeability protruding thick coal seam of the present invention.

[0039] The regional gas enhanced drainage method for a single low-permeability protruding thick coal seam comprises the following steps:

[0040] (a) Excavate a rock roadway 4 in the crack zone of the rock formation 2 above the mining coal seam 1, and punch out several low-level layer-penetrating boreholes 5 downwards, and the low-level layer-penetrating boreholes 5 pass through the described mining coal seam 1;

[0041] (b) In the rock roadway 4, drill several high-level layer-through drilling holes 6 downward, and the high-level layer-through dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com