High-speed 3D weaving method for seamless underwear machine

A seamless underwear machine, underwear machine technology, applied in the direction of weft knitting, knitting, textiles and paper making, etc., to achieve the effect of strong adaptability, improve production efficiency, and eliminate the effect of delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] At present, before weaving 3D patterns, the domestic mainstream seamless underwear machines require the master plate maker to reduce the speed to 70 rpm in advance in the editing pattern chain, so as to achieve a good 3D pattern effect. The high-speed 3D knitting method of the seamless underwear machine in the present invention will be specifically described below.

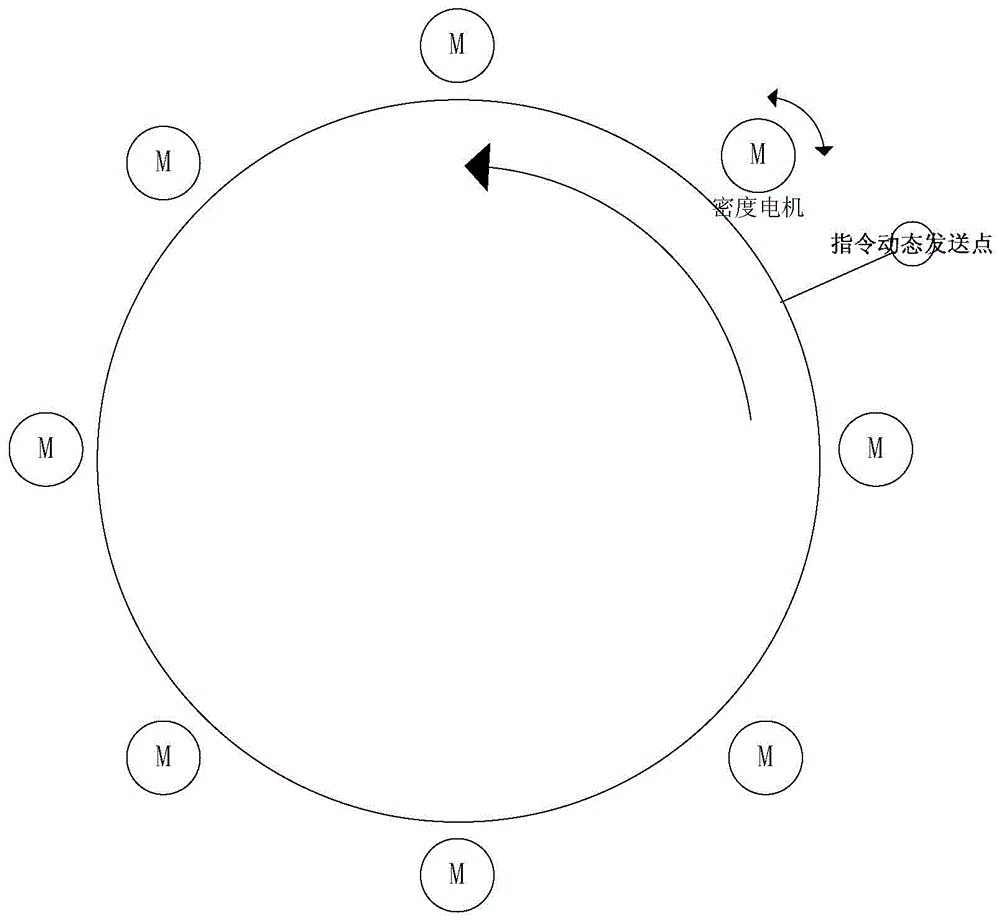

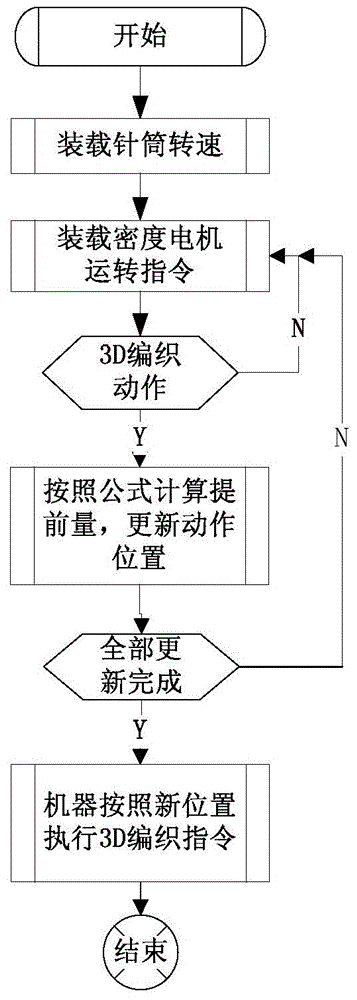

[0017] like figure 1 , figure 2 As shown, the high-speed 3D knitting method of the seamless underwear machine in this embodiment includes the following steps:

[0018] S1. After the pattern data is loaded, the control system of the underwear machine pre-reads the needle cylinder speed (unit: revolution / minute) in the fabric chain and records it;

[0019] S2. The control system of the underwear machine pre-reads the operation command of the density motor in the fabric chain, including the action position of the density motor, the travel direction of the density motor and the travel value of the density mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com