Laminated glass intermediate film with shielding capacity and high transparency as well as preparation method thereof

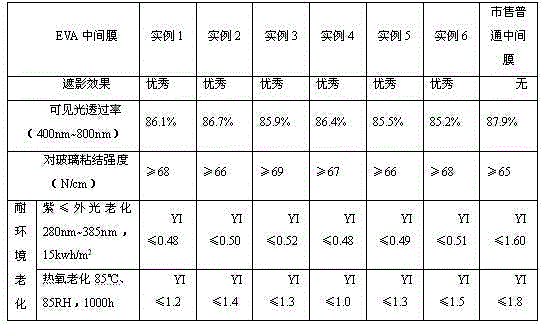

A high light transmittance, laminated glass technology, applied in the field of safety laminated glass, can solve the problems of not meeting the needs of safety, not protecting privacy, and disappearing privacy protection effects, etc., achieving high bonding strength of glass, excellent shading effect, The effect of good environmental aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A high light transmittance laminated glass interlayer film with a shadow-shading effect, comprising the following components in terms of weight percentage (wt%): EVA 93.5wt% with a vinyl acetate content of 33%, nano-silicon dioxide 2wt%, acrylic resin 2wt%, 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane 1.6wt%, trimethylolpropane trimethacrylate 0.3wt%, phosphite tris(2, 4-di-tert-butylphenyl) ester 0.2wt%, bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate 0.2wt%, γ-methacryloyloxy Propyltrimethoxysilane 0.2wt%.

[0025] The preparation method of this embodiment: according to the above weight ratio, add inorganic additives, organic additives, peroxide crosslinking agents, auxiliary crosslinking agents, phosphite antioxidants, hindered amine light stabilizers and coupling agents to EVA raw materials, mixed evenly, and then extruded and casted into a film by a casting machine.

[0026] This embodiment can also be prepared according to the following method: mix inorganic add...

Embodiment 2

[0029] A high light transmittance laminated glass interlayer film with a shadow-shading effect, comprising the following components in terms of weight percentage (wt%): EVA94.4wt% with a vinyl acetate content of 28%, 0.5wt% nano-silicon dioxide, poly Silicone resin 2.5wt%, tert-butylperoxycarbonate-2-ethylhexyl 0.8wt%, triallyl isocyanurate 0.5wt%, trinonylphenyl phosphite 0.3wt%, bis (2,2,6,6-tetramethyl-4-piperidinyl) sebacate 0.5wt%. γ-Aminopropyltriethoxysilane 0.5wt%.

[0030] The preparation method of this embodiment is the same as that of Example 1.

[0031]

Embodiment 3

[0033]A high light transmittance laminated glass interlayer film with a shadow-shading effect, comprising the following components in terms of weight percentage (wt%): EVA93.3wt% with a vinyl acetate content of 28%, 0.5wt% nano calcium carbonate, styrene Resin 3wt%, 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane 1.6wt%, triallyl cyanurate 0.3wt%, trinonylphenyl phosphite 0.6wt%, polysuccinate (4-hydroxy-2,2,6,6-tetramethyl-1-piperidine ethanol) ester 0.5wt%. γ-methacryloxypropyltrimethoxysilane 0.2wt%.

[0034] The preparation method of this embodiment is the same as that of Example 1.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com