Head extension device of multi-station belt conveyor

A telescopic device and belt conveyor technology, applied in conveyors, transportation and packaging, etc., can solve the problems of unstable telescopic structure of telescopic belt conveyors, small range of activities, inability to meet on-site operations, etc., saving financial resources, increasing the range of activities, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

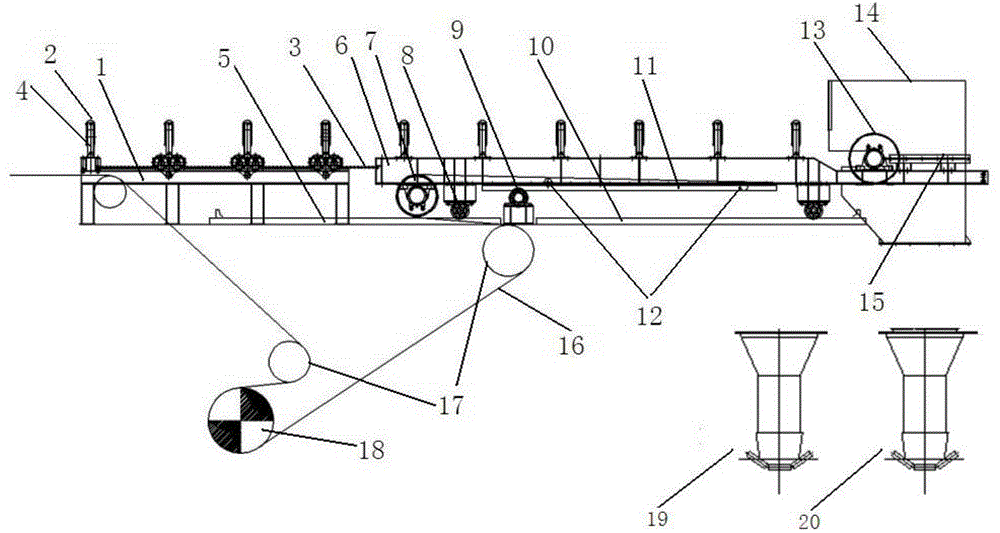

[0016] The telescopic device of the head of the multi-station belt conveyor can be made into two-position cross, three-position cross, or even more position cross according to the application requirements, such as figure 1 Shown, it is two intersections: be the first station 19, the second station 20. The walking mode of the device is a rack drive track walking mode, but is not limited thereto, and can also walk through a chain drive track. The overall layout of the device can be divided into two types: high bracket type and floor type: high bracket arrangement, that is, the telescopic head is supported by the high bracket above the cross-transposed tape machine, and the two are arranged in one space; floor type layout, That is, the telescopic head is arranged on the top floor of the cross-transposed tape machine, and the two are arranged in two spaces.

[0017] This embodiment is a floor-standing arrangement, including a sub-beam 1 fixed on the bottom transverse steel plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com