Cutter for razor nets of razors

A technology for cutting knives and razors, applied in the field of razor processing equipment, can solve the problems of cumbersome processes, low efficiency, and long grinding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

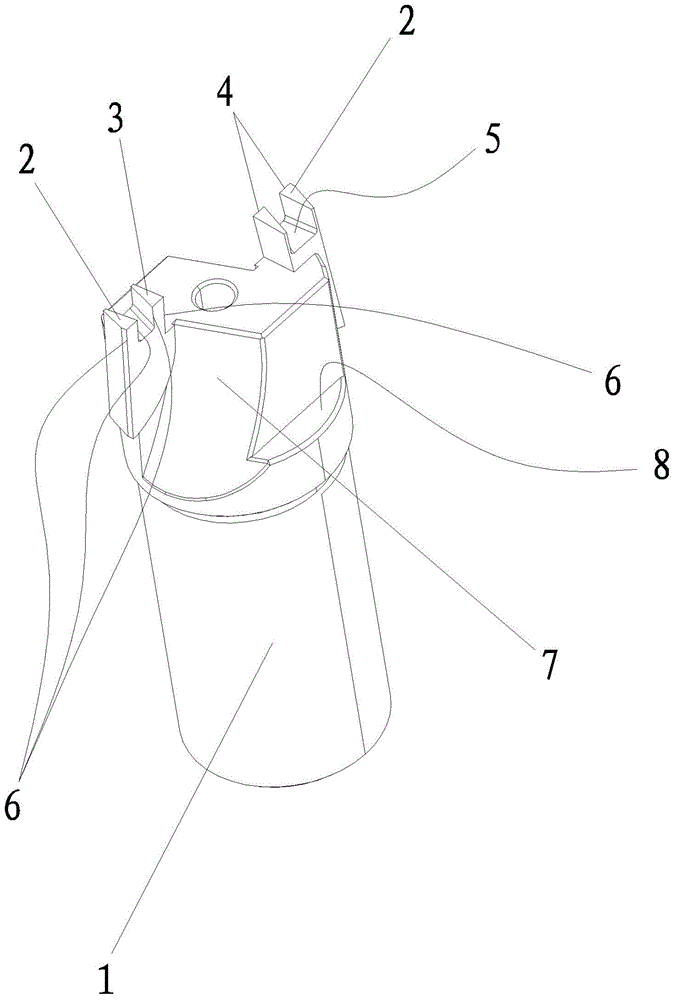

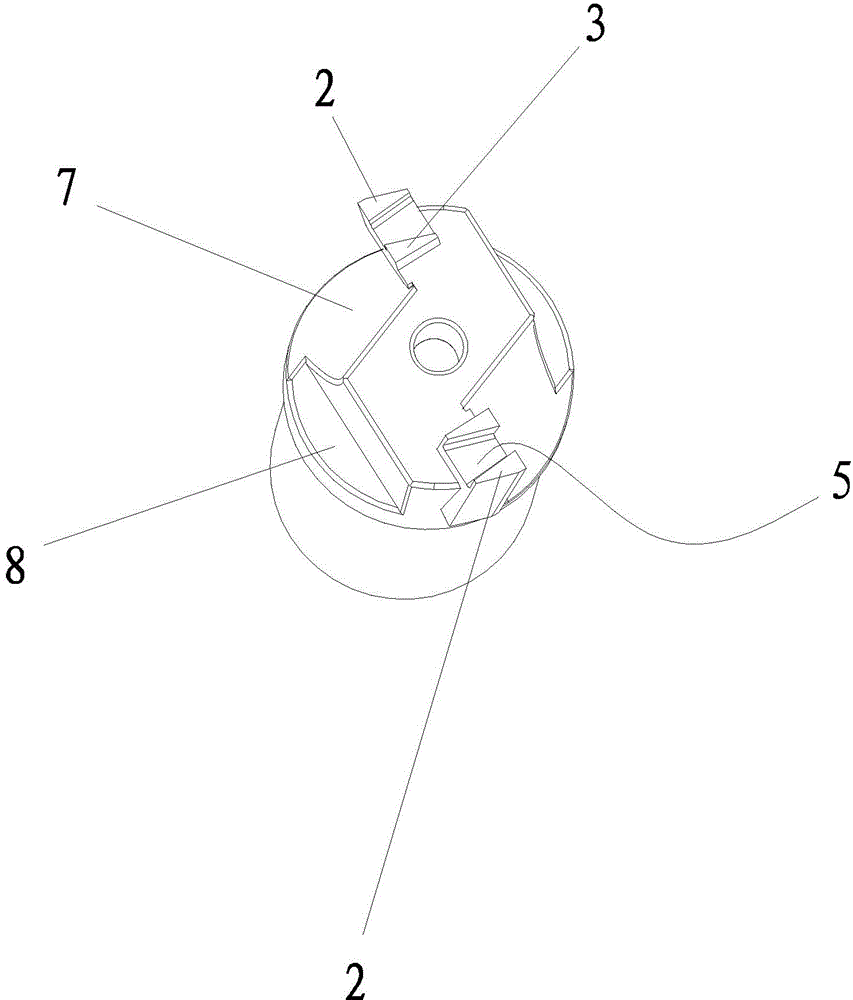

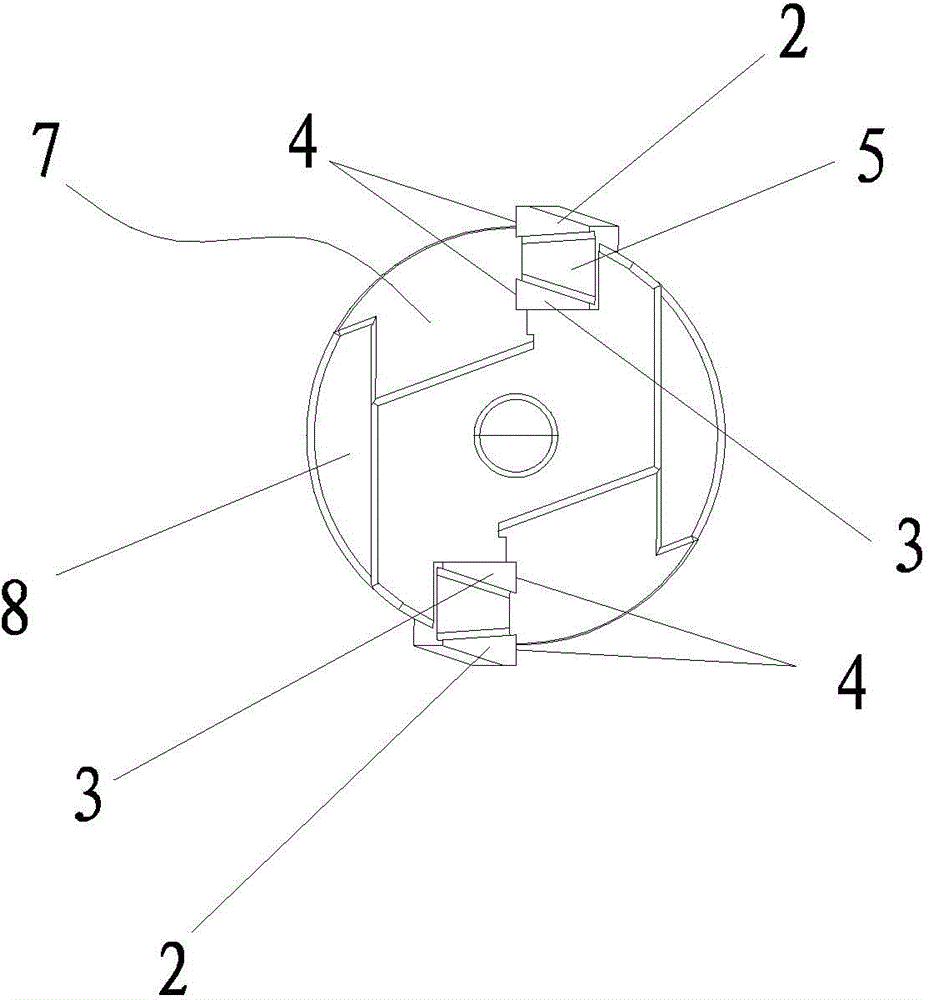

[0018] Such as figure 1 , figure 2 , image 3 Shown, the cutting knife of razor knife net of the present invention, it comprises cutter head 1 and the outer cutter head 2 that is used to cut outer ring groove and the inner cutter head 3 that is used to cut inner ring groove, the cutter head seat 1 To be connected with the machine tool, the outer cutter head 2 and the inner cutter head 3 are located at the same end of the cutter head seat 1, and a main cutting edge 4 is arranged on the outer cutter head 2 and the inner cutter head 3, and the main cutting edge 4 is responsible for the main cutting work , is the main tool for groove forming, there is a radial gap between the outer cutter head 2 and the inner cutter head 3, the gap accommodates the rib between the two grooves, on the outer cutter head 2 and the inner cutter head 3 Also all are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com