System for controlling automatic material charging of multiple mechanical powder forming presses

An automatic feeding and mechanical technology, which is applied in the field of powder metallurgy automation equipment and workshop equipment layout, can solve the problems of endangering the health of close-range operators, increasing the amount of cleaning work, and a large amount of dust, so as to optimize material transfer routes and optimize equipment The effect of the layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

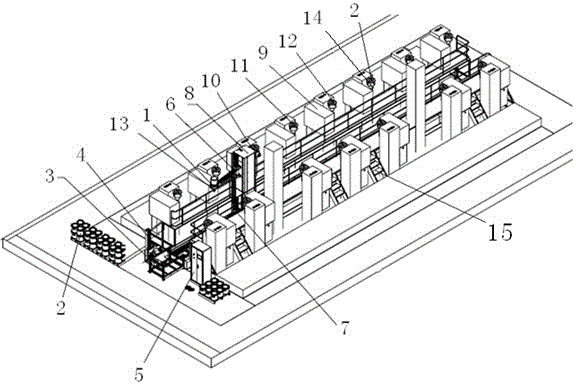

[0018] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

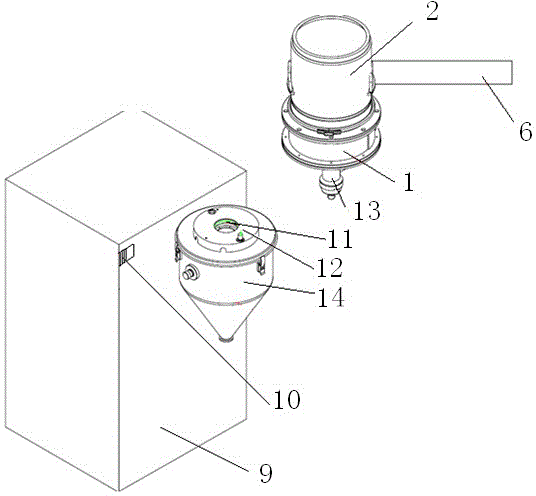

[0019] The present invention works and implements in this way, a system that can control multiple mechanical powder molding presses for automatic feeding, it includes a feeding unit, a feeding unit, a feeding unit and a maintenance unit, characterized in that: The feeding unit consists of a funnel-shaped stainless steel cone cover 1, a stainless steel bucket 2, a stacker truck 3 and an electric clamping device 4. The feeding unit consists of a control cabinet 5, a clamping swing arm mechanism 6, a horizontal feeding track 7, The box type lifting mechanism 8 is composed of a press machine 9, a press machine proximity switch and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com