Passenger oxygen mask and breathing bag for oxygen mask

An oxygen mask and breathing bag technology, applied in the field of breathing bags, can solve problems such as increasing the number of hose interfaces, and achieve the effect of simplifying manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

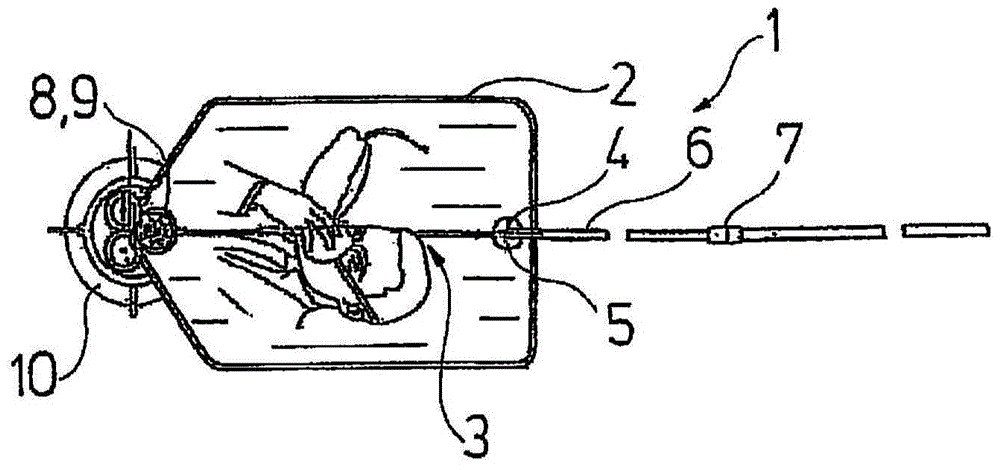

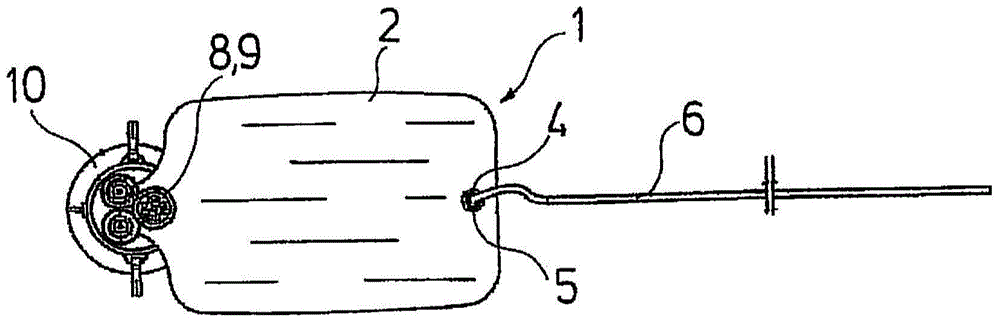

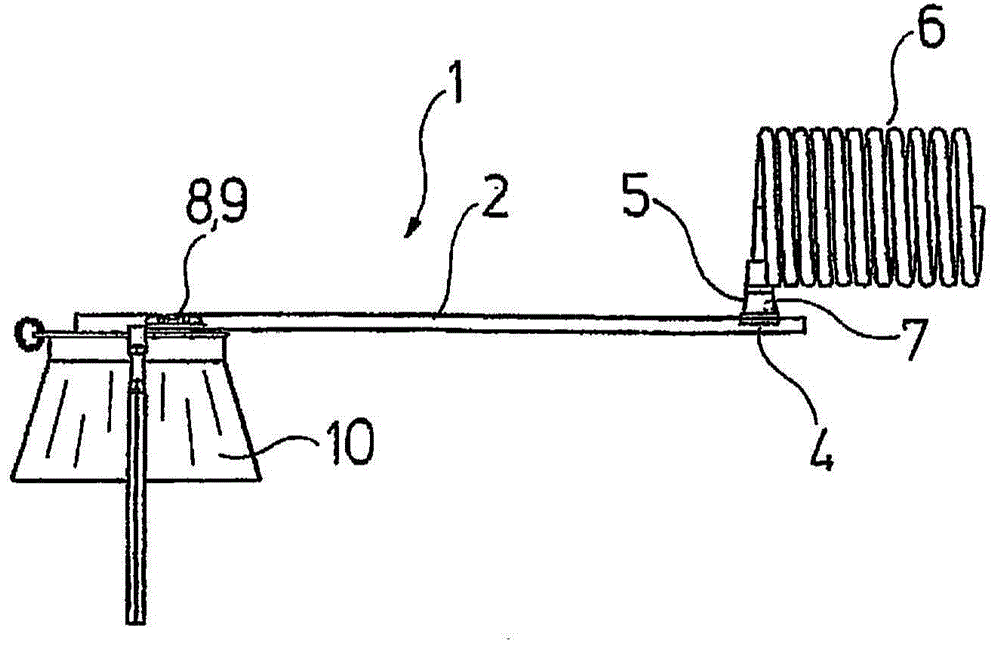

[0040] figure 1 It is an oxygen mask 1 applicable to aircraft passengers according to the prior art. The oxygen mask 1 comprises a breathing bag 2 made of PVC in which a stretch relief tether 3 is provided for reinforcement purposes. An oxygen inlet 4 is provided on the breathing bag 2 , at which a sealing gasket (not shown) welded to the breathing bag 2 is arranged and has a connection piece 5 for receiving a hose 6 . The hose 6 is also made of PVC. The flow display device 7 is inserted into the hose 6 , which interrupts the hose line, thus creating two further connection points or connections for the hose 6 . On the opposite side of the inlet 4 of the breathing bag 2 is an outlet 8 at which a sealing gasket (not shown) is likewise welded to the breathing bag 2 , which sealing gasket is fixed on the mask by means of a connecting element 9 . The connecting element 9 is located in the breathing bag 2 and presses the sealing gasket of the breathing bag 2 onto the predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com