Composite post insulator

A technology of lined pipes and metal ends, applied in the direction of supporting insulators, insulators, electrical components, etc., can solve problems such as insufficiency and aging, and achieve the effect of reducing self-weight, enhancing load-bearing and compressive capacity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

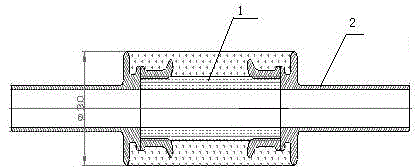

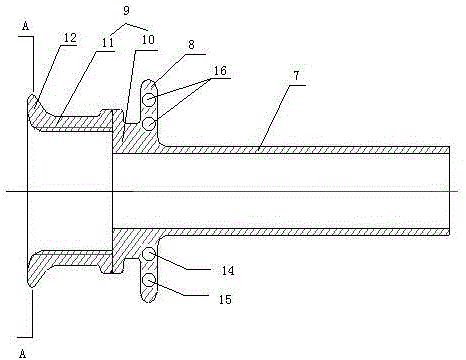

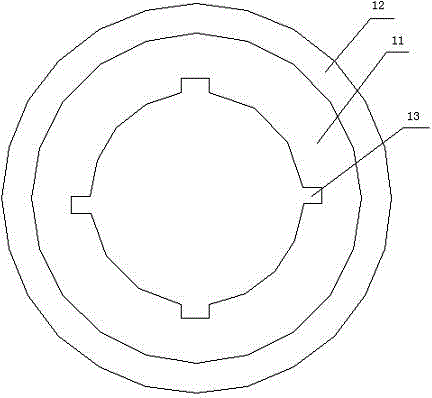

[0016] As shown in the figure, a composite post insulator includes a liner pipe 1 and a metal end pipe 2, wherein a metal end pipe 2 is respectively fixed at both ends of the liner pipe 1, and the liner pipe 1 includes a hollow fiberglass core Rod 3, the fiberglass mandrel 3 is covered with a layer of glass fiber tape 4, the glass fiber tape 4 is covered with a layer of heat-shrinkable tape 5, and the heat-shrinkable tape 5 is covered with a layer of Demoulding PTFE tape layer 6, the metal end pipe 2 includes a tube body 7, a circle of umbrella skirt 8 is provided on the outer surface of the tube body 7, the diameter of the umbrella skirt 8 is 30mm, and one end of the umbrella skirt 8 is provided with There is a clamping structure 9, the clamping structure 9 includes a connecting seat 10, the cross-sectional shape of the connecting seat 10 is a T-shaped structure, one end of the connecting seat 10 is fixedly connected with the umbrella skirt 8, and the other end is welded with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com