A control method for hot rolling rolling stock preparation in slab warehouse

A control method and slab warehouse technology, applied in the information field, can solve problems such as collapse accidents, prolonging material preparation time, difficulty and cost of slab increasing warehouse logistics management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

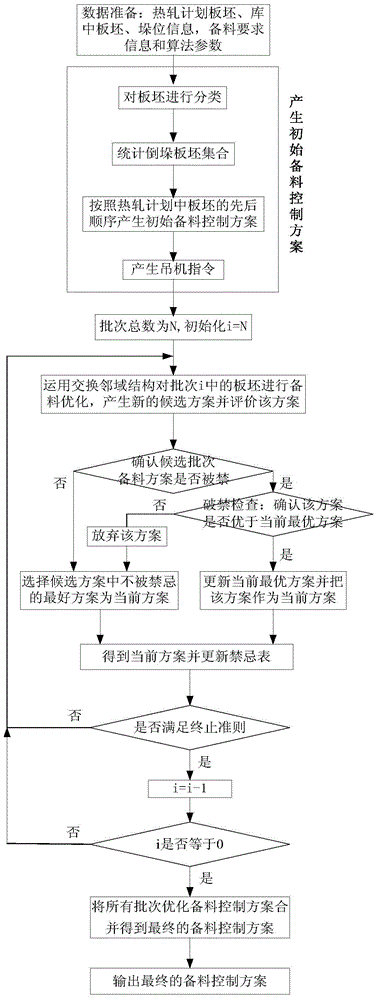

[0056] The control method of hot rolling rolling stock preparation in the slab storehouse of the present embodiment, such as figure 2 shown, including the following steps:

[0057] Step 1: Obtain the slab information of the hot rolling plan, the slab information in the slab warehouse, the stack information in the slab warehouse and the material preparation requirement information;

[0058] Among them, the hot rolling plan slab information includes: slab number, tapping mark, contract number, storage area, material number, stack number, billet weight, billet width, billet length, rolling plan number and batch number;

[0059] The slab information in the slab warehouse includes: slab number, tapping mark, contract number, storage area, material number, stack number, slab weight and slab width;

[0060] The stack information in the slab warehouse include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com