Fixtures for specimen samples in in-situ testing of microscopic properties of functional materials

A technology for in-situ testing and specimen samples, applied in the directions of analyzing materials, measuring devices, strength characteristics, etc., can solve problems such as difficulty in realization and inability to combine loading under various working conditions, and achieve the effect of high precision and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

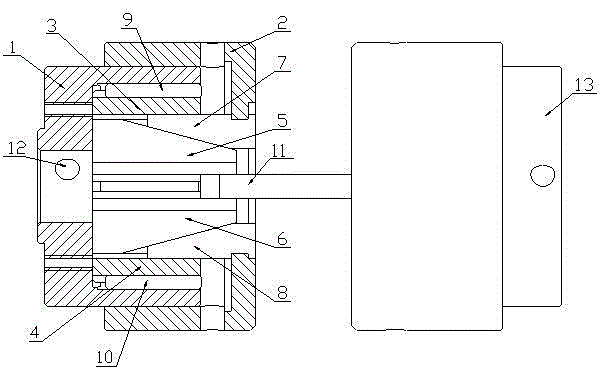

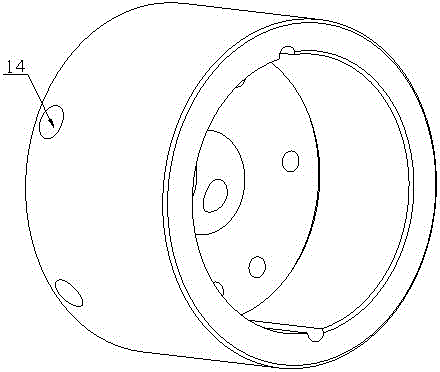

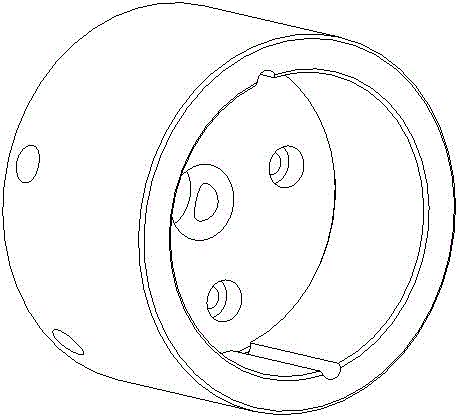

[0022] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 7 As shown, the fixture of the present invention used for in-situ testing of the microscopic properties of functional materials is composed of two pairs of fixtures with the same structure, wherein the fixture I with steps is connected to the shaft coupling through bolts and pins, and the fixture I The difference is that the clamp body II13 of the clamp II has no steps, and the clamp II without the steps is connected with the tension and torque sensor through the countersunk bolts to realize the dynamic real-time measurement of tension / pressure and torque; the structures of the clamps I and II are: The clamp body Ⅰ1 and the tightening sleeve 2 are connected by threads, and one end of the tightening sleeve 2 goes deep into the grooves of the compression wedges Ⅰ, Ⅱ7, 8. When the tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com