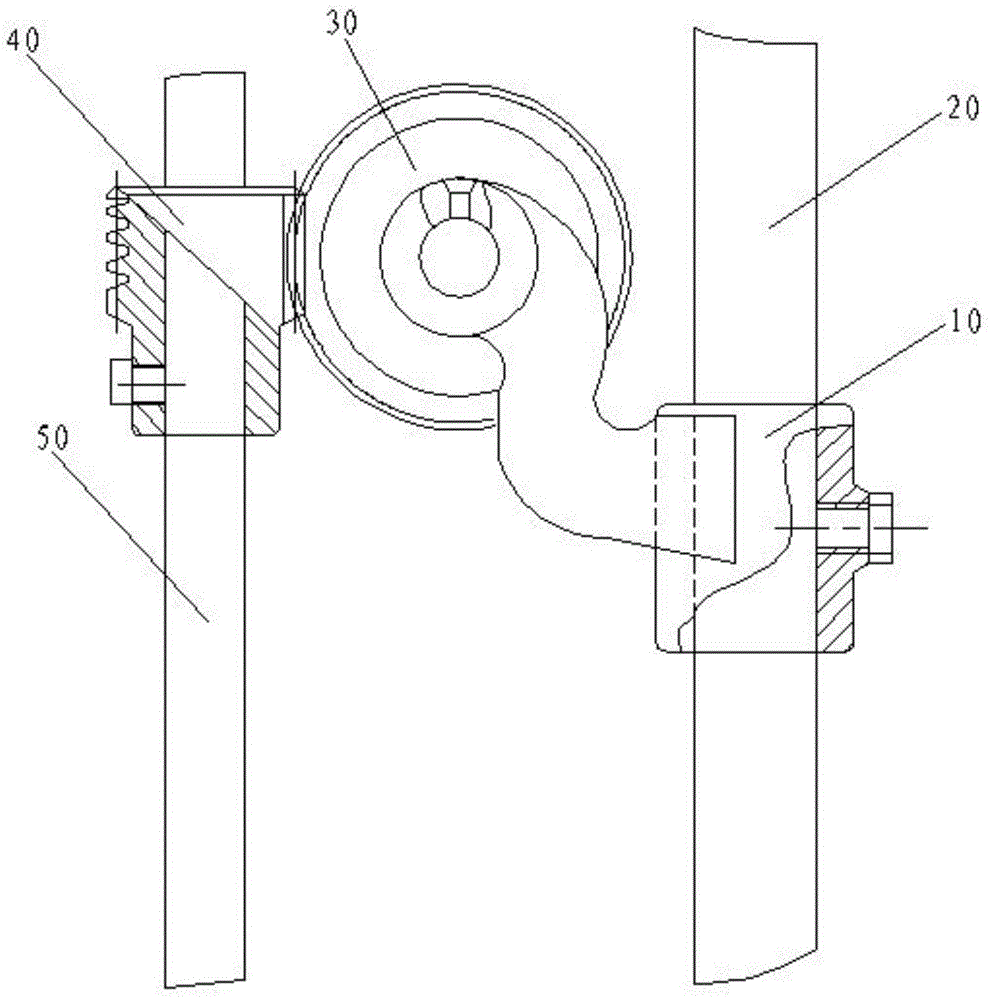

Worm gear and worm reducer transmission device

A technology of worm gear and transmission device, which is applied in the direction of gear transmission device, transmission device, transmission device parts, etc. It can solve the problems of inconvenient adjustment of product density, influence on weaving efficiency and quality, and large transmission resistance of worm gear and worm gear, so as to save raw materials , not easy to wear, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

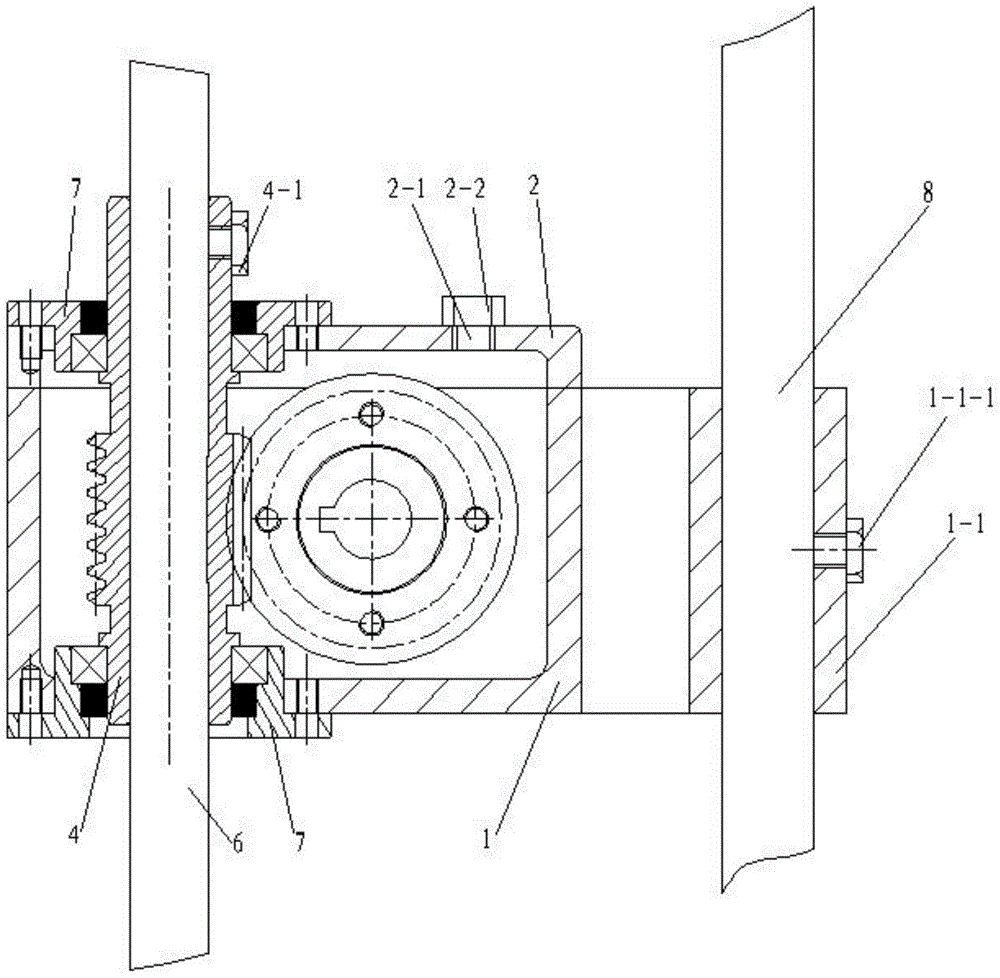

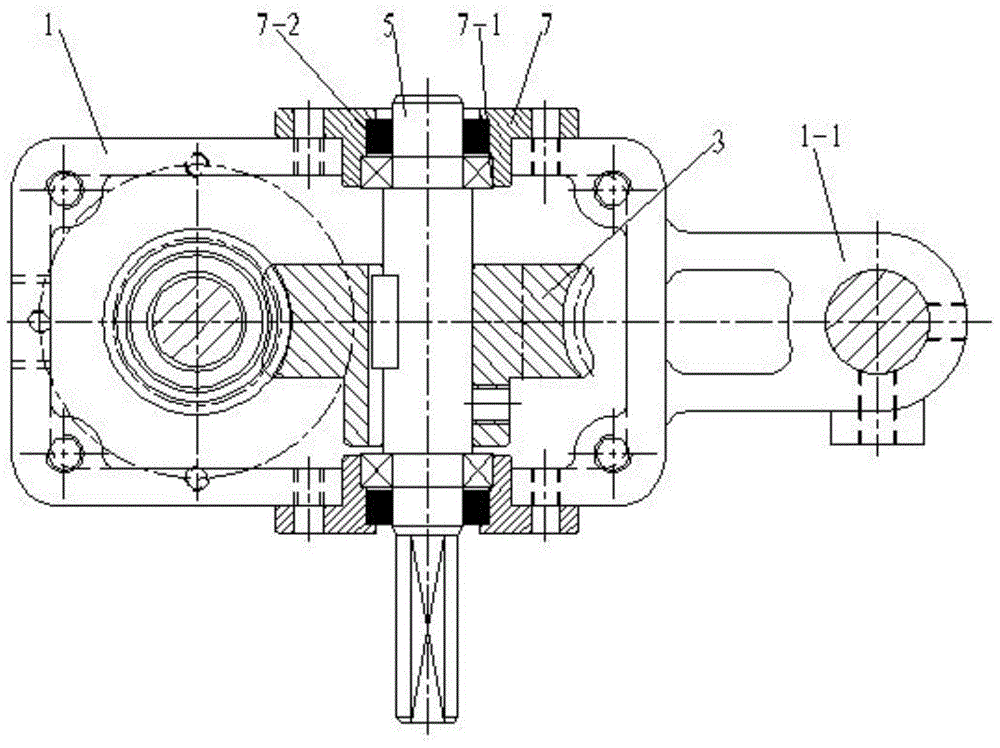

[0019] Such as figure 2 and image 3 As shown, a special worm gear reducer transmission device for knitting machines, including a box body 1, a box cover 2, a worm wheel 3, a worm screw 4, a worm wheel shaft 5 and a worm shaft 6, and the worm wheel 3 and the worm screw 4 mesh with each other to form a speed reduction mechanism; The worm shaft 5 passes through the worm wheel 3, the worm shaft 6 passes through the worm 4, the casing is provided with a transverse through hole and a vertical through hole, the worm shaft 5 passes through the transverse through hole of the casing 1, and the worm shaft 6 Pass through the vertical through hole of the box body 1; both ends of the worm gear shaft 5 and the worm shaft 6 have end covers 7 to fix them on the box body, and the end covers 7 are provided with bearings 7-1 and sealing rings 7-2; the box cover 2 is connected to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com