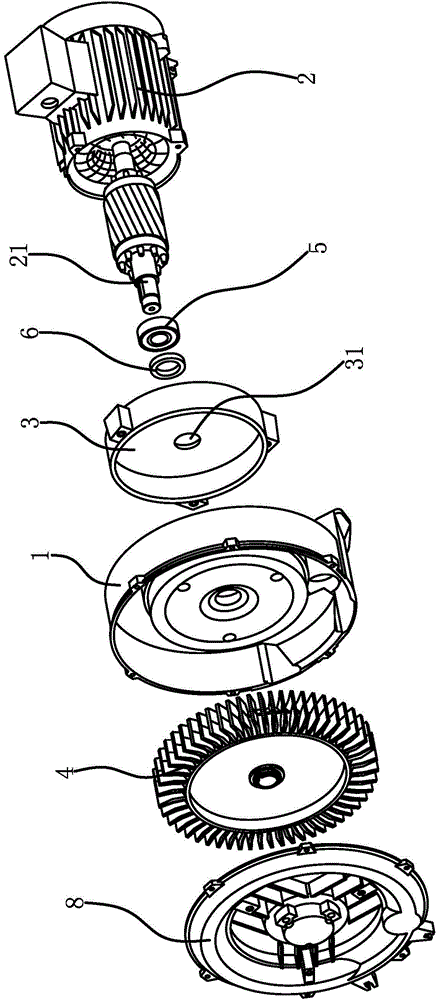

High-pressure blower

A high-pressure blower and air barrel technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as motor damage, achieve the effects of prolonging service life, good toughness, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

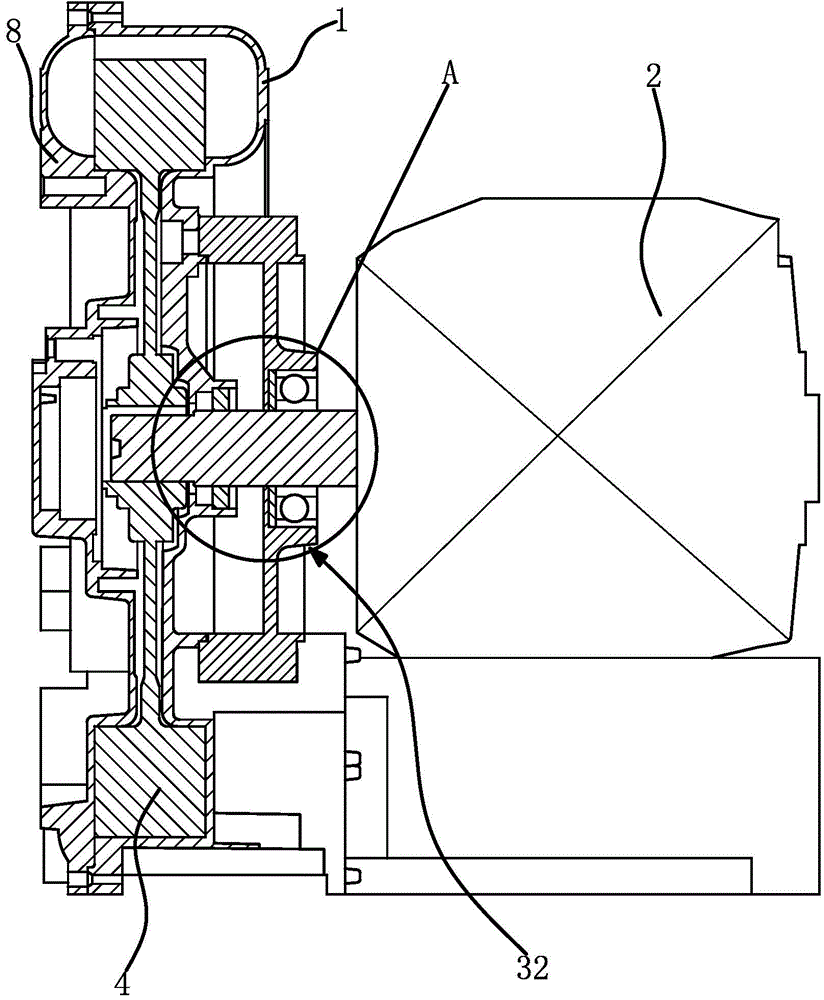

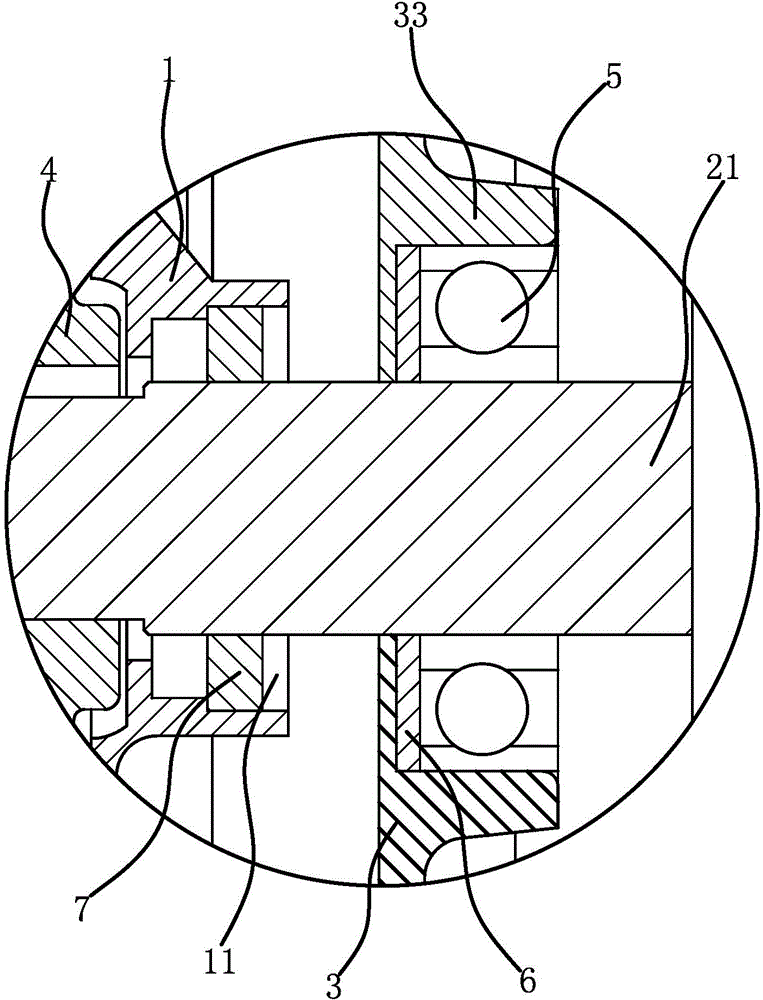

Method used

Image

Examples

Embodiment 1

[0042] Weigh the raw materials according to the composition elements and mass percentages of the bearing cover plate and the bearing described in Example 1 in Table 1, and the composition elements and mass percentages of the bearing cover plate and the bearing have a certain influence on the performance of the bearing cover plate and the bearing. , and its preparation process also has a great influence on the performance of the final bearing cover plate and bearing. The preparation method of the bearing cover plate and the bearing includes a forging process and heat treatment; in the forging process, the initial forging temperature is 1110°C, and the final forging temperature is 810°C; in the heat treatment process, quenching is performed when the temperature is 860°C, After that, keep warm for 3 hours; temper when the temperature is 480°C, and then keep warm for 3 hours after tempering.

Embodiment 2

[0044] Weigh raw materials according to the composition elements and mass percentages of the bearing cover plate and bearing described in Table 1 Example 2, the composition elements and mass percentages of the bearing cover plate and bearing have certain influence on the performance of the bearing cover plate and bearing , and its preparation process also has a great influence on the performance of the final bearing cover plate and bearing. The preparation method of the bearing cover plate and the bearing includes a forging process and heat treatment; in the forging process, the initial forging temperature is 1100°C, and the final forging temperature is 780°C; in the heat treatment process, quenching is performed when the temperature is 850°C, After that, keep warm for 2 hours; temper when the temperature is 470°C, and then keep warm for 3 hours after tempering.

Embodiment 3

[0046] Weigh the raw materials according to the composition elements and mass percentages of bearing cover plate and bearing described in Table 1 Example 3, and the composition elements and mass percentages of bearing cover plate and bearing have certain influence on the performance of bearing cover plate and bearing , and its preparation process also has a great influence on the performance of the final bearing cover plate and bearing. The preparation method of the bearing cover plate and the bearing includes a forging process and heat treatment; in the forging process, the initial forging temperature is 1140°C, and the final forging temperature is 830°C; in the heat treatment process, quenching is performed when the temperature is 950°C, After that, keep warm for 4 hours; temper when the temperature is 520°C, and then keep warm for 4 hours after tempering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com