Automatic nozzle cleaning device and method

A technology of automatic cleaning and nozzle mounting plate, which is applied in printing and other directions, can solve the problems that the printing unit cannot automatically clean the nozzle, affect the quality of the printing picture, and cannot realize automatic cleaning, so as to ensure the quality of the printing picture, reduce disconnection and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

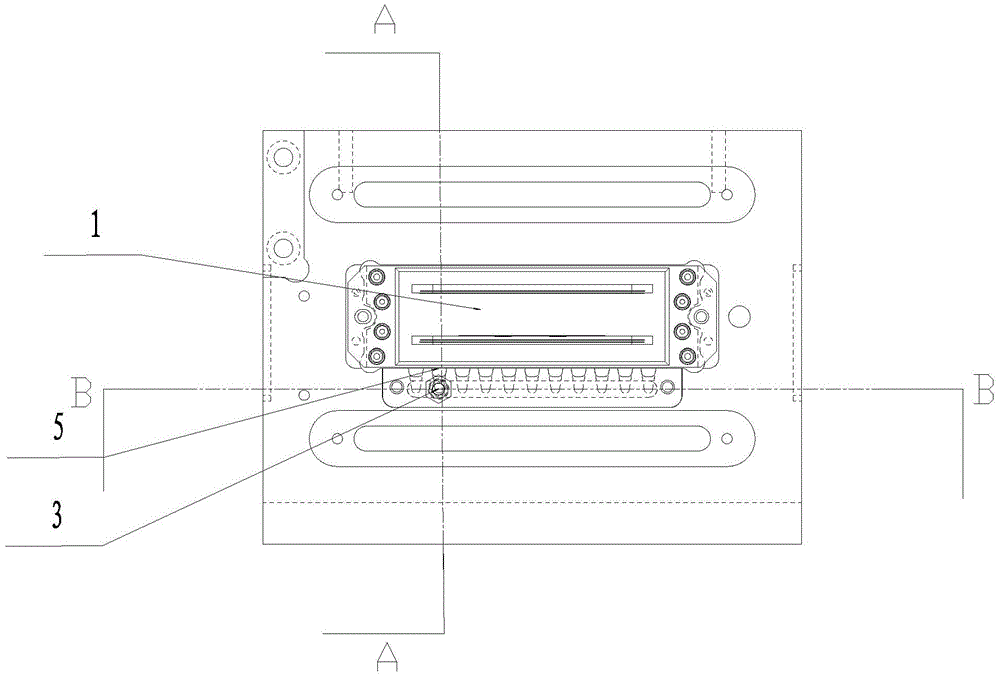

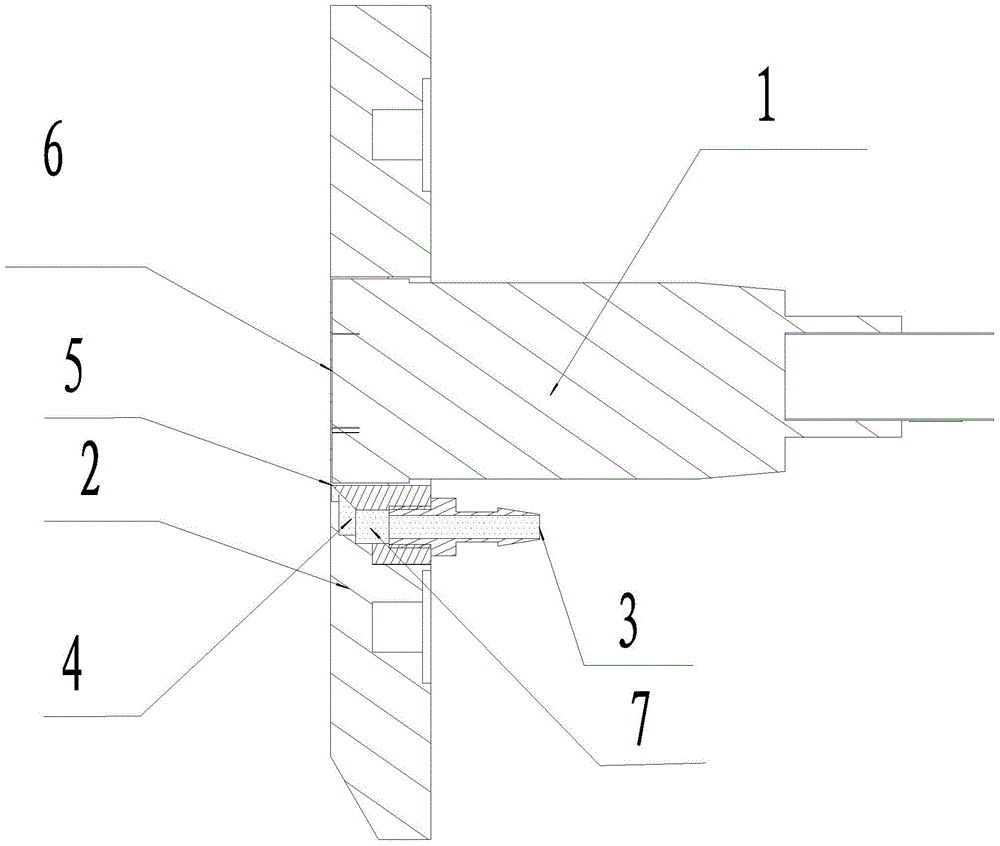

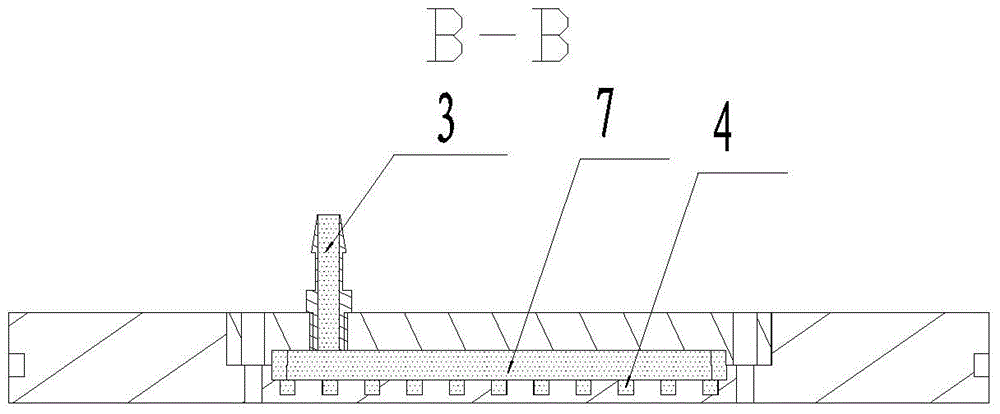

[0020] Such as Figure 1 to Figure 3 As shown, the nozzle automatic cleaning device includes a printing nozzle 1, a nozzle mounting plate 2 and an air blowing device. The printing nozzle 1 is fixed on the nozzle mounting plate 2, and the air blowing device is located on the nozzle mounting plate 2. The air blowing device includes Air hole 3, air blowing hole 4 and air pump, air intake hole 3 is positioned at the right below the shower head, and described air inlet hole 3 comprises air nozzle and strip-shaped airflow channel 7, and described air nozzle is connected with strip-shaped airflow channel 7 Through, the air blowing holes 4 are a plurality of holes located in the nozzle mounting plate 2, the holes are located directly below the nozzle mounting plate 2, and they communicate with the strip-shaped air flow channels 7 respectively, and the holes The opening tends to become smaller along the airway direction of the airflow, and there are one or more stages of structures wit...

Embodiment 2

[0022] Nozzle automatic cleaning device, including printing nozzle 1, nozzle mounting plate 2, blowing device and blowing device fixing plate, printing nozzle 1 is fixed on the nozzle mounting plate 2, and the blowing device is fixed on the fixing plate of the blowing device. Nozzle 1 is opposite, and described air blowing device comprises air inlet 3, air blowing hole 4 and air pump, and described air pump will be pressed in the air inlet 3, and the gas in air inlet 3 flows into air blowing hole 4, and the gas in air blowing hole 4 The airflow is blowing directly to the print head 1 from the narrow air hole 5 to the nozzle surface 6 of the print head.

Embodiment 3

[0024] An automatic nozzle cleaning method, printing with a printing nozzle fixed on a nozzle mounting plate, and blowing air at the printing nozzle through an air blowing device located on the nozzle mounting plate, the specific blowing steps are as follows: the air is pressed into the In the air inlet hole, the gas in the air inlet hole flows into the air blow hole, and the gas in the air blow hole is blown out from the long and narrow air hole, and the air flow blown out is blown toward the nozzle surface parallel to the print head. Through the air flow, impurities such as paper powder, toner powder, and dust particles on the surface of the nozzle are removed, so as to realize the automatic cleaning method of the nozzle. The air intake hole adopts an air nozzle and a long strip air flow channel, the gas entering the air intake hole flows through the air nozzle and enters the long strip air flow channel, and the air blow hole is located directly below the nozzle mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com