Laminate press-fit production line

A technology of production line and plate pressing, which is applied in the field of laminate devices to achieve the effects of strong continuity, improved work efficiency, and powerful functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

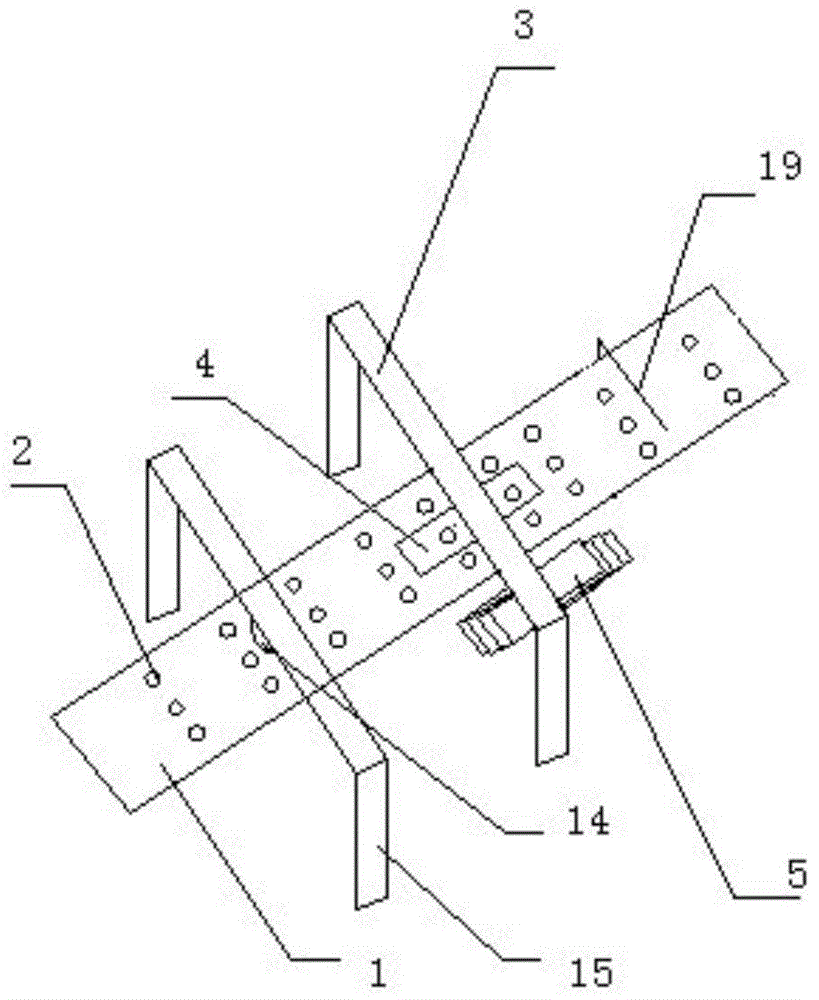

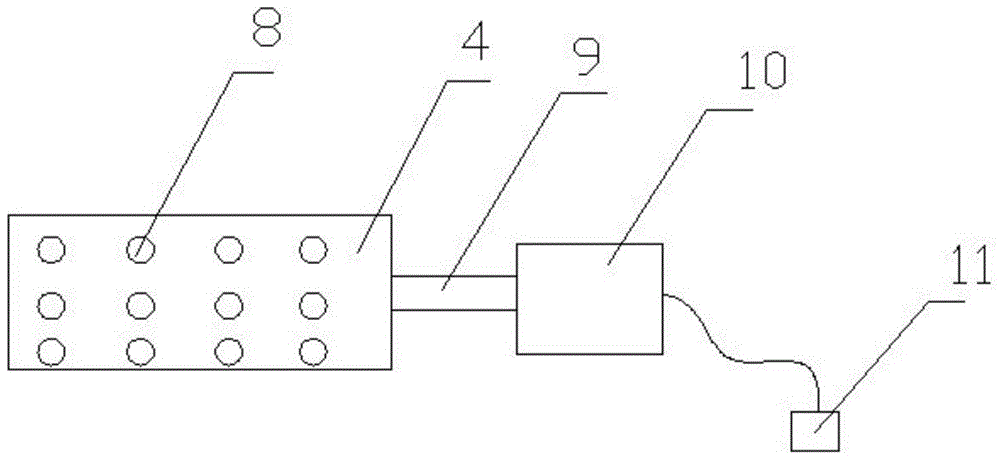

[0042] Such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, in this embodiment, it includes a conveyor belt 1, a glue brushing mechanism, a pressing mechanism, a laminate box 5 and a glue removing mechanism. Located behind the pressing mechanism, the glue brushing mechanism and the glue removing mechanism are located on the side of the conveyor belt, and the pressing mechanism is horizontally above the conveyor belt.

[0043] The pressing mechanism includes a beam 3, a vertical beam, a cylinder and a suction plate 4. There are two vertical beams, which are respectively located on both sides of the conveyor belt 1. The beam 3 is welded on the vertical beam and is located above the conveyor belt 1. A slide rail and a servo motor are provided, a connecting block is clamped in the slide rail, the servo motor drives the connecting block to slide in the slide rail, one end of the cylinder is connected to the connecting block, and the other end is connected to the suct...

Embodiment 2

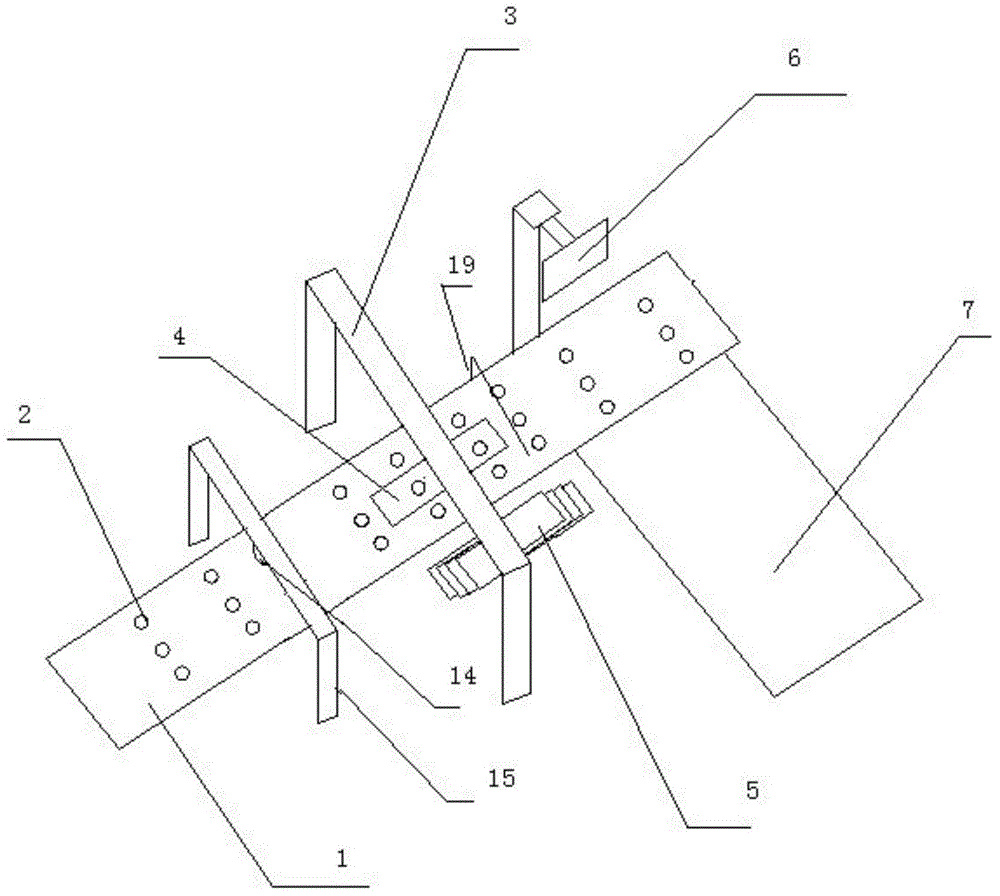

[0052] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, in this embodiment, it includes a conveyor belt 1, a glue brushing mechanism, a pressing mechanism, a laminate box 5 and a glue removing mechanism. Located behind the pressing mechanism, the glue brushing mechanism and the glue removing mechanism are located on the side of the conveyor belt, and the pressing mechanism is horizontally above the conveyor belt.

[0053] The pressing mechanism includes a beam 3, a vertical beam, a cylinder and a suction plate 4. There are two vertical beams, which are respectively located on both sides of the conveyor belt 1. The beam 3 is welded on the vertical beam and is located above the conveyor belt 1. A slide rail and a servo motor are provided, a connecting block is clamped in the slide rail, the servo motor drives the connecting block to slide in the slide rail, one end of the cylinder is connected to the connecting block, and the other end is connected to the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com