Constant level tray assembly

A technology of combining components and trays, applied in the field of machinery, can solve the problems of reducing the separation efficiency of the trays, uneven distribution of gas and liquid phases in the trays, dry liquid, etc., and achieves the effects of reducing equipment consumables, simple installation, and improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the drawings and embodiments.

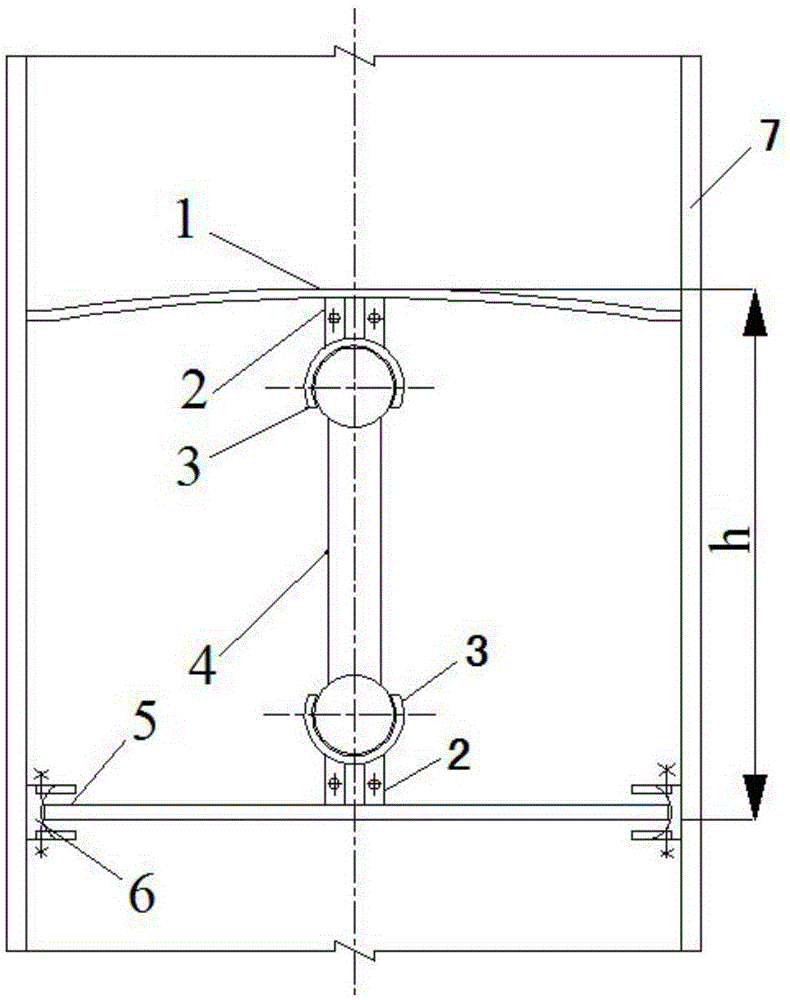

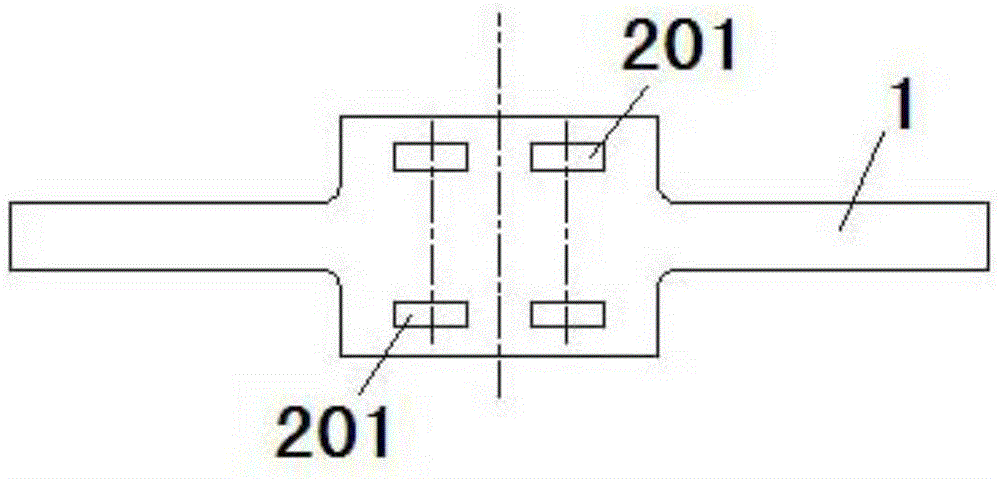

[0022] See figure 1 , figure 2 , image 3 , The constant-level tray assembly component of the present invention is used to install tray 5 in tray tower 7, and select different materials according to different process conditions; it includes a piece of two ends welded to the inner wall of tray tower 7 The arch beam 1 is used to bear the quality of the tray 5 and the process operation medium. In order to facilitate the load-bearing, the middle of the arch beam 1 is raised upward, and the two ends are respectively located at the two ends of a certain horizontal diameter in the tower; The load-bearing capacity of the arch beam 1 should be designed according to the inner diameter of the tower and the tangent angle θ of the convex arc in the middle of the arch beam is 10°-30°. From figure 1 It can be seen that the upper and lower ends of the vertical connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com