Single-formwork button making machine

A single template and buckle machine technology, which is applied in shoemaking machinery, leather, clothing, etc., can solve the problems of no operability, large position error, and low tool efficiency, and achieve cost and time savings, simple operation, and easy transformation partial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

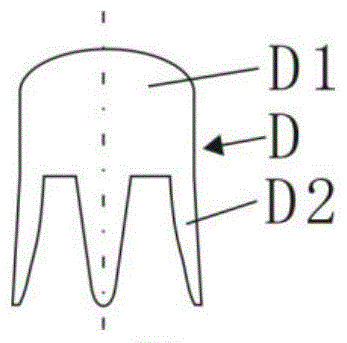

[0044] The single-formwork fastening system includes a single-formwork fastening machine and a formwork component C used in conjunction with the machine.

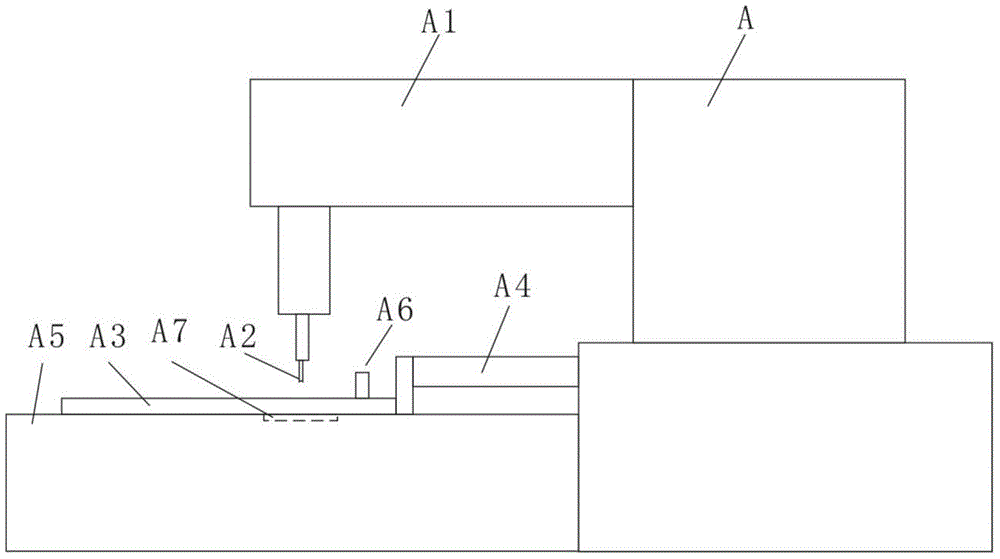

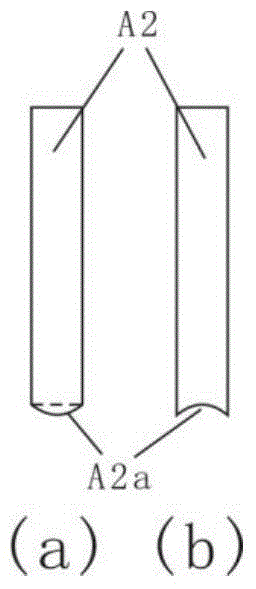

[0045] Such as figure 2 As mentioned above, the main machine A is based on the improvement of the computerized pattern machine, the needle in it is replaced by the punch A2, the fixed frame A3 is remade according to the template component C, and the working table A5 is set to cooperate with the punch A2. The bottom module A7. The original computer pattern machine including the installation needle is now the punch head A2 and the machine head A1, the X and Y axis moving frame A4 is below the machine head A1, the fixed frame A3 is installed on the X, Y axis moving frame A4, and the fixed frame A3 is below Work surface A5.

[0046] Described main frame A comprises the punch A2 that is installed on the machine head A1 and is installed on the X, Y-axis mobile frame A4 and is positioned at the fixed mount A3 below punch A2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com