Electricity-saving system capable of selecting and stably outputting voltage

A technology for stabilizing output and output voltage, applied in the field of power-saving devices, can solve problems such as shortening the service life of capacitor parts, increasing equipment installation costs, and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

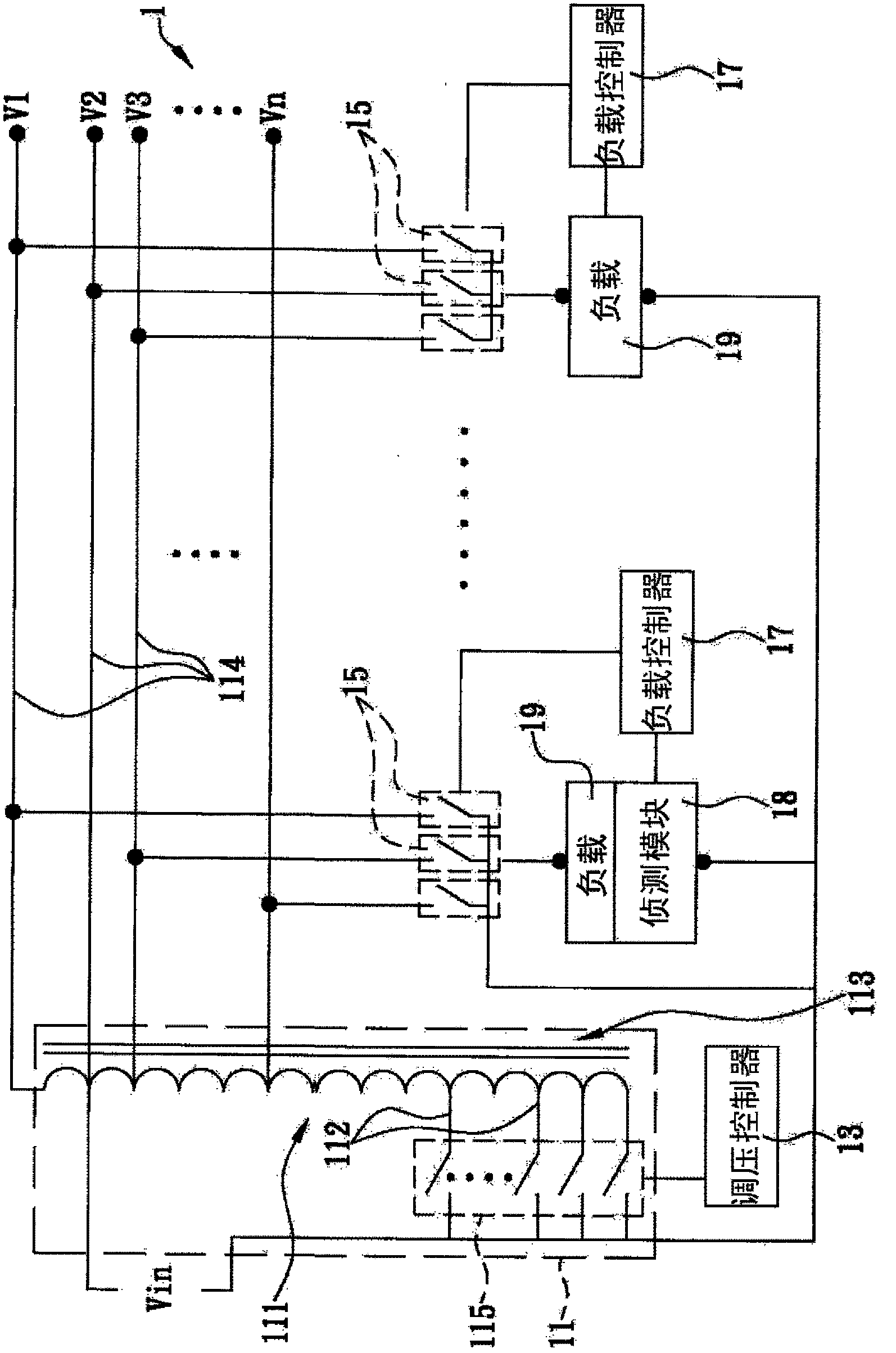

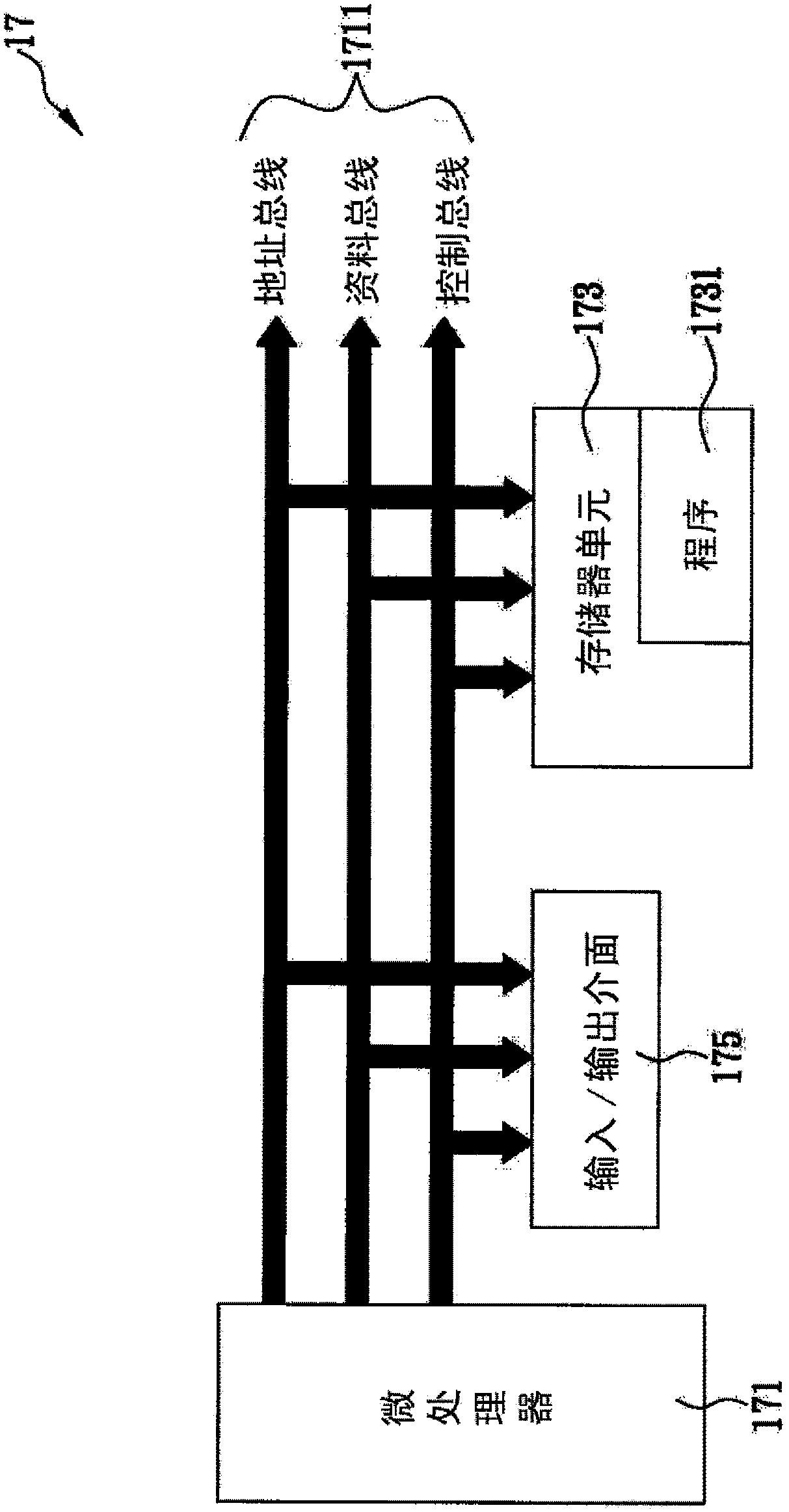

[0012] The present invention is a power-saving system capable of selecting and stabilizing the output voltage, please refer to figure 1 As shown, the power saving system 1 includes a multi-output voltage transformer 11, a voltage regulation controller 13, a plurality of voltage selection switches 15 and a plurality of load controllers 17. In a preferred embodiment, the multi-output voltage transformer 11 is an autotransformer (that is, a transformer with one line group), mainly because the autotransformer with the same capacity is compared with the isolation transformer (that is, a transformer with two line groups), not only the autotransformer The size is smaller, and the loss or cost is smaller than the isolation transformer, which helps to reduce the production cost of the industry, but, although figure 1 It is drawn in the form of an autotransformer circuit, but in other embodiments of the present invention, the industry can also use various suitable transformers as the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com