A Conjugate Transverse Shear Design Method for Planar Link Mechanism

A planar linkage mechanism and design method technology, applied in calculation, special data processing applications, instruments, etc., can solve problems affecting tool life and unsatisfactory shearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

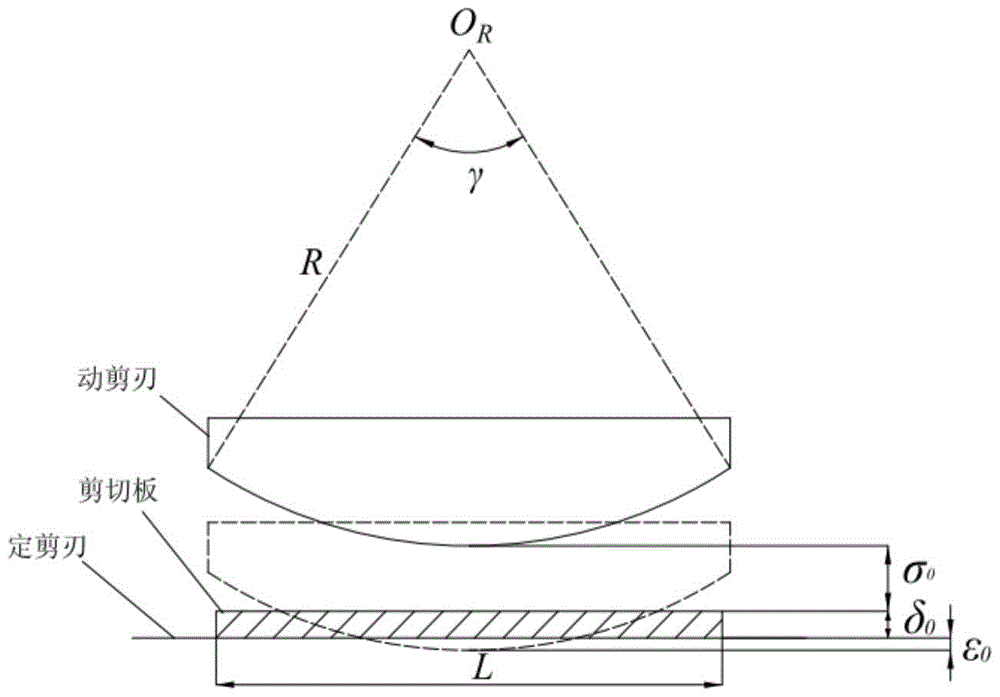

[0036] The shearing process parameters of a type of rolling shears are shown in Table 1.

[0037] Table 1 shearing process parameters

[0038]

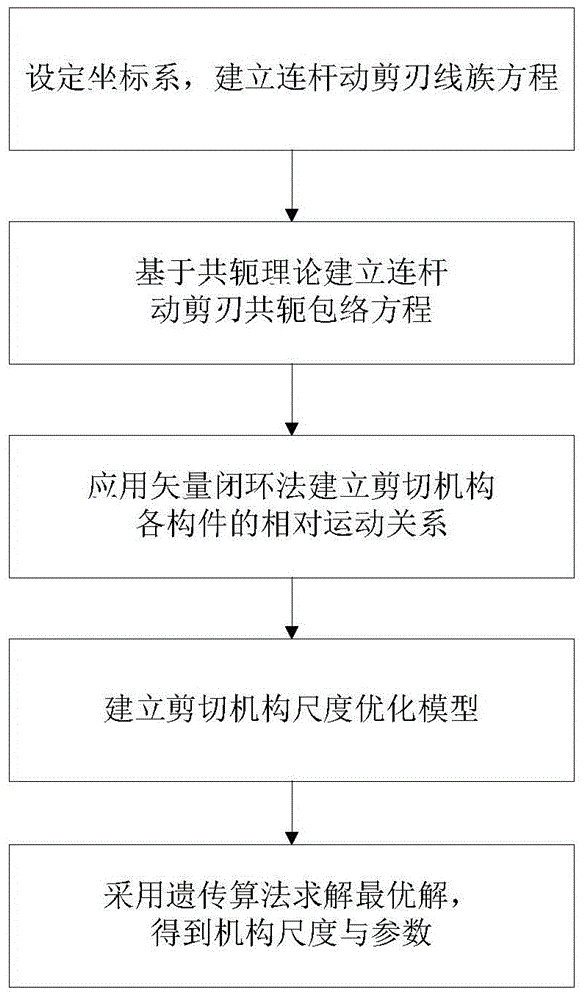

[0039] A design method of conjugate transverse shear of planar linkage mechanism, its operation flow is as follows figure 1 shown. Specifically:

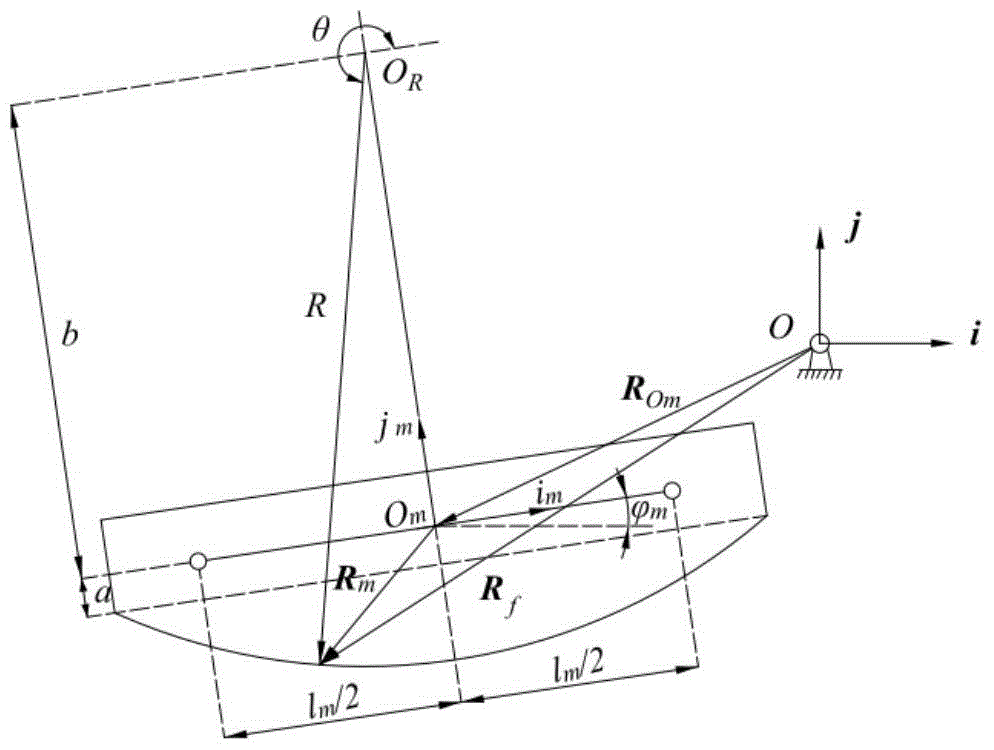

[0040] Step 1: Set the coordinate system of the shearing mechanism and determine the relative relationship of the two degrees of freedom. Such as image 3 shown. Take a fixed hinge point O of the shearing mechanism as the coordinate origin, take the horizontal direction as the x-axis, and the vertical direction as the y-axis to set a fixed coordinate system S f ;Moving coordinate system S m Consolidated on the moving shear blade, a coordinate axis passes through the two hinge points, and takes the middle point l of the two living hinge points m / 2 is the coordinate origin O m . The center of the arc of the scissors is at y m axis; moving coordinate system S m with the set coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com