Drawing device and drawing method

A technology of main scanning direction and sub-scanning, which is applied in the direction of exposure device, optics, and optomechanical equipment in the photolithography process, which can solve the problems that the automatic focusing mechanism cannot function normally, and the drawing accuracy of the band-shaped area is reduced, so as to improve the drawing Accuracy, easy parts management, effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the drawings, the size and number of each part may be exaggerated or abbreviated in order to facilitate understanding.

[0069]

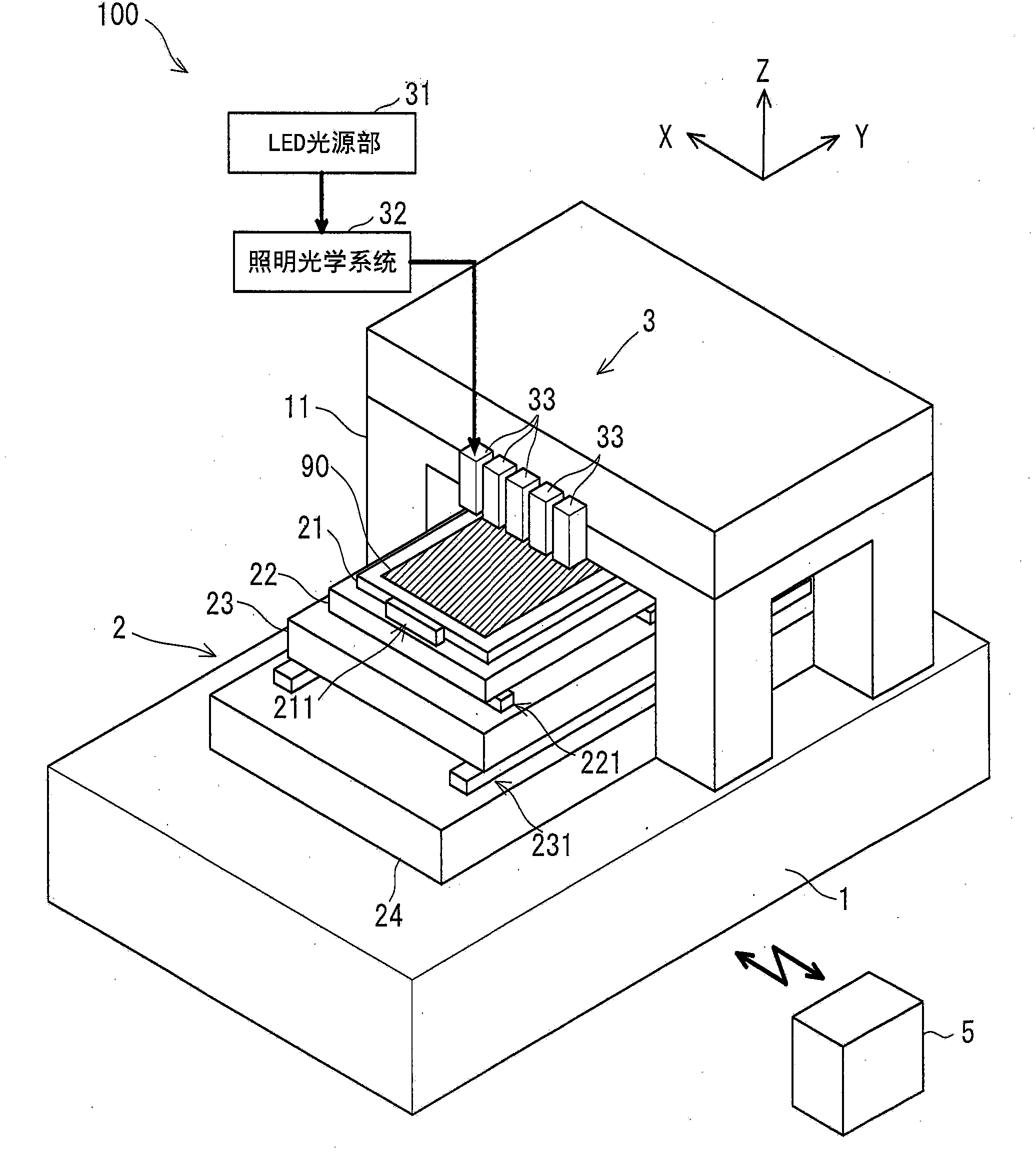

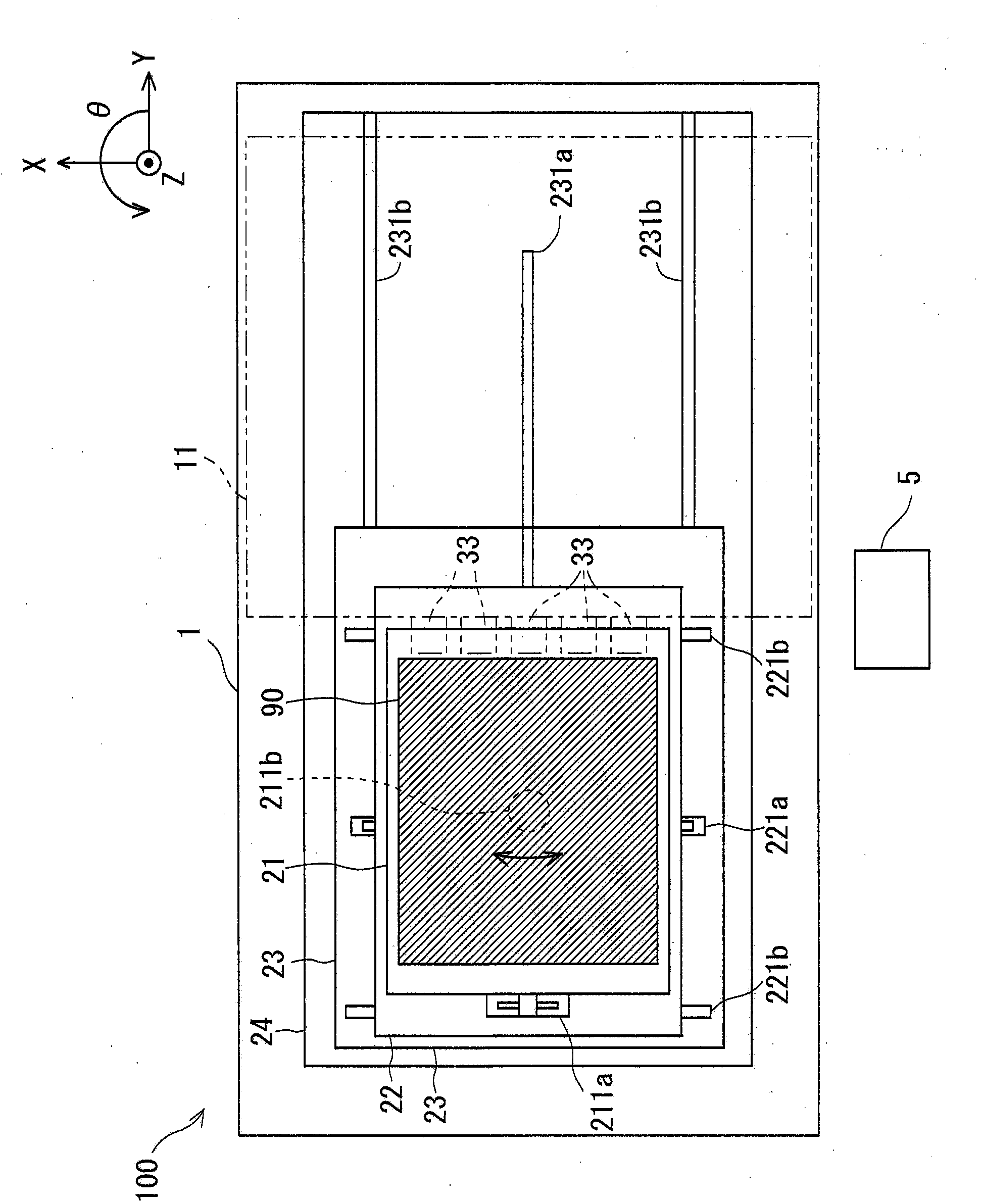

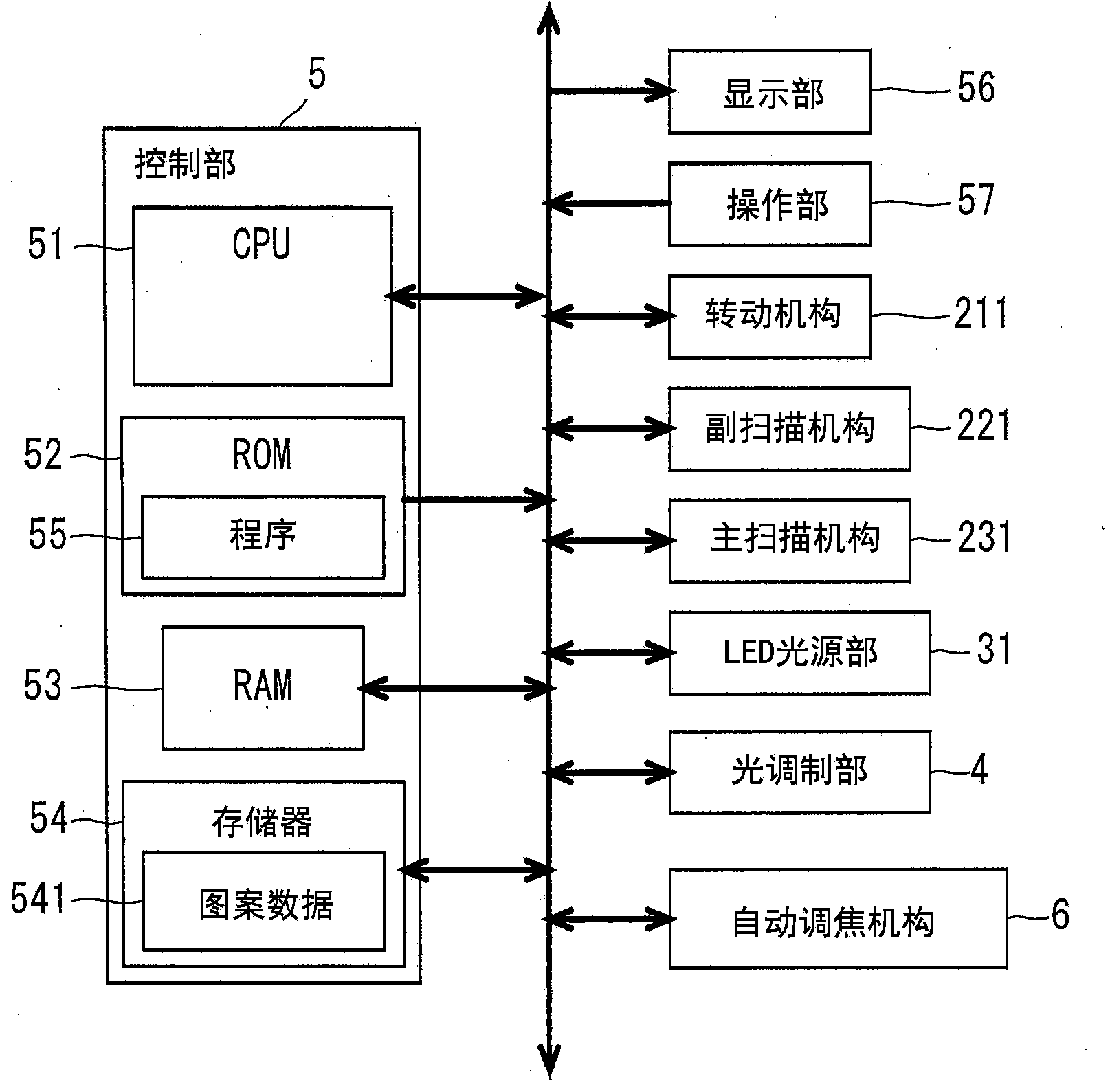

[0070] figure 1 It is a perspective view showing the outline of the drawing device 100 of the embodiment. in addition, figure 2 It is a plan view showing the outline of the drawing device 100 . and, image 3 is a bus wiring diagram of the drawing device 100 . exist figure 1 In the figure, for the convenience of illustration and description, the Z-axis direction is defined as the vertical direction, and the XY plane is defined as the horizontal plane. However, this is defined for the convenience of grasping the positional relationship, and does not limit each direction described below. The same applies to the following figures. In addition, in figure 2 In , for convenience of description, the bridging structure 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com