Measurable ultrasonic probe adjusting seat

A technology of adjusting seat and ultrasonic wave, which can be used in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., which can solve the problems of unfavorable production efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

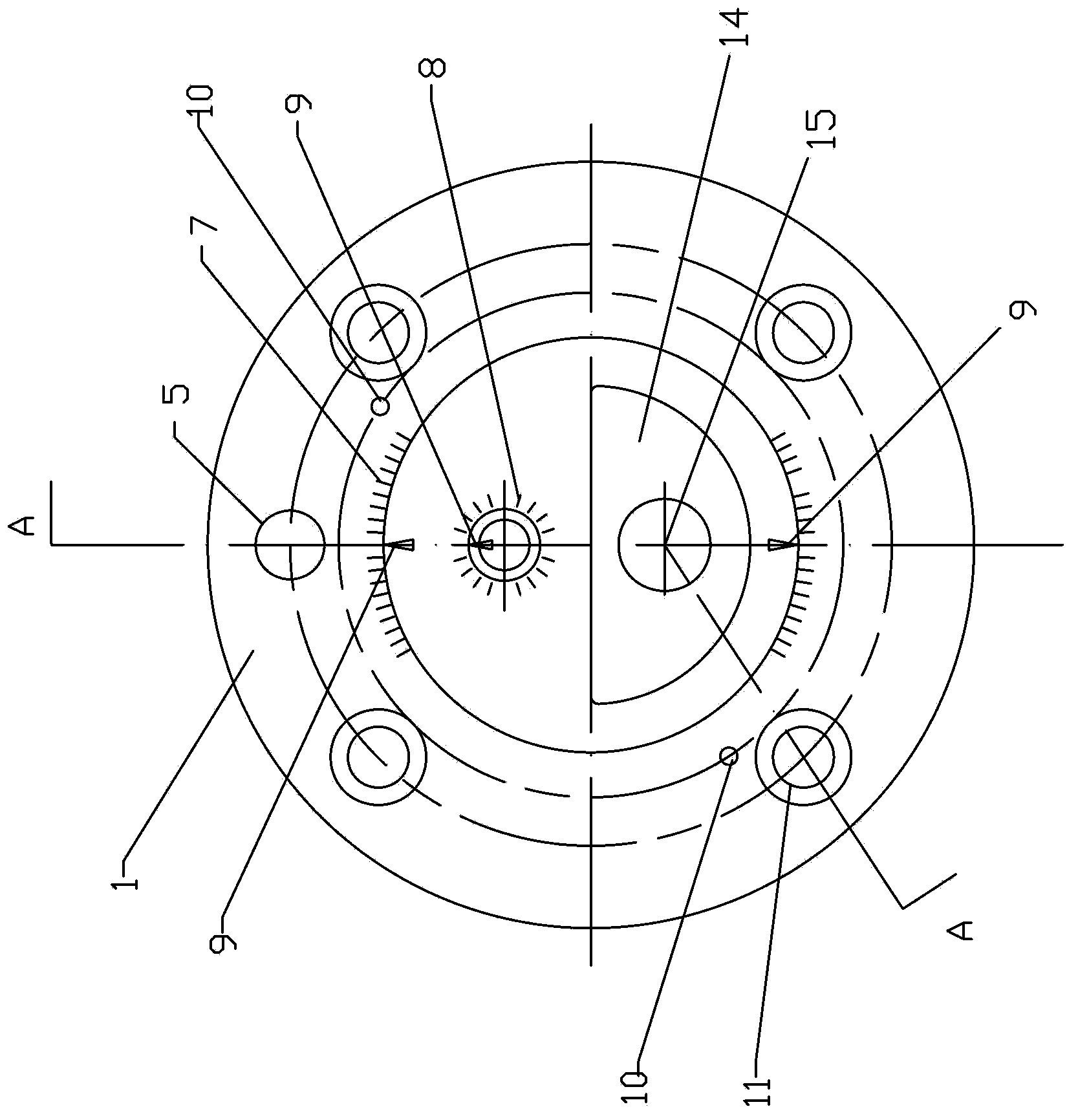

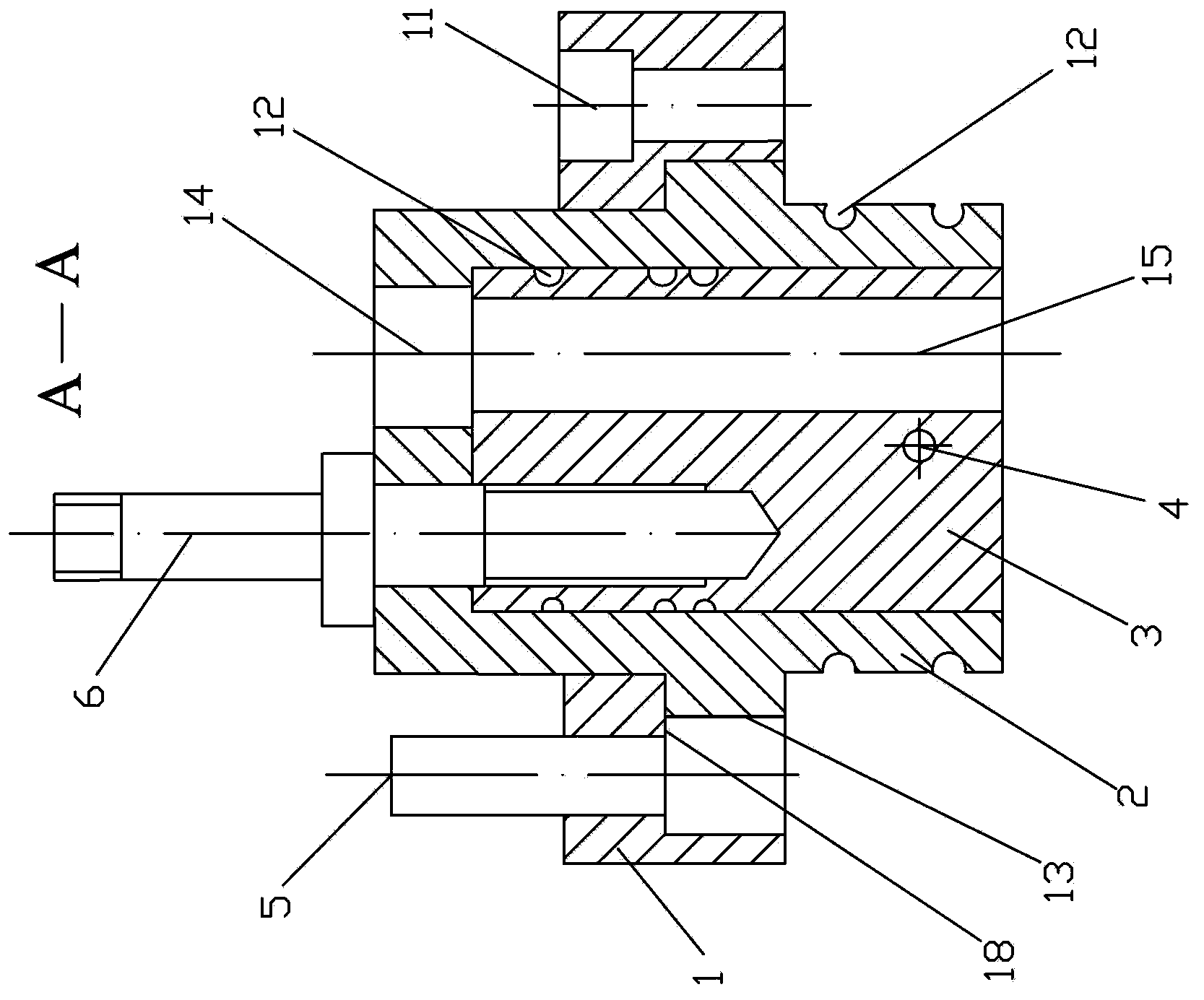

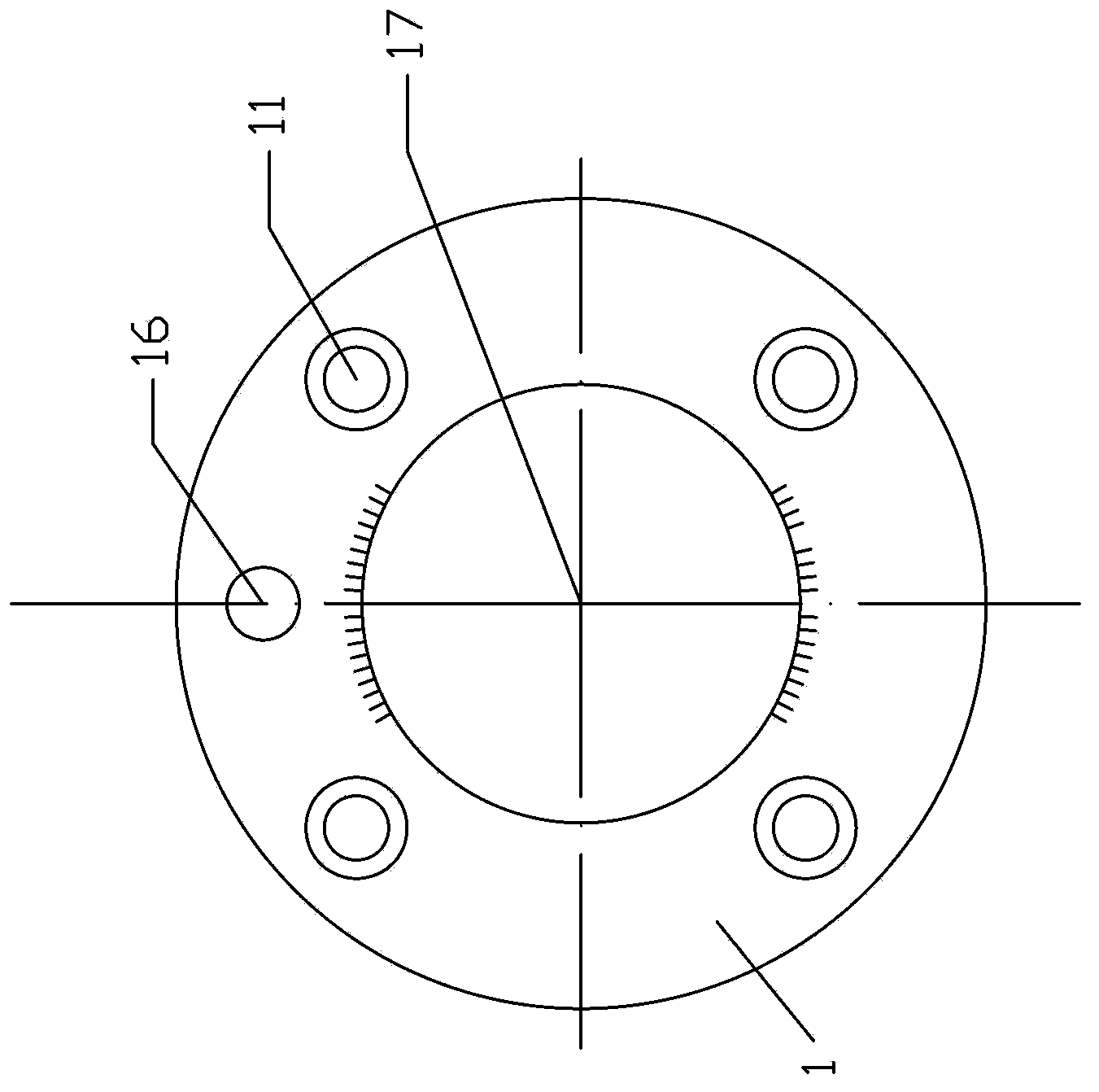

[0017] Such as figure 1 As shown, the measurable ultrasonic probe adjustment seat installed on the ultrasonic flaw detector of the present invention includes: a fixed seat 1, an eccentricity adjustment seat 2, a spacing adjustment seat 3, a fixing screw 4, an adjustment rod 5 with a gear on the bottom, and an adjustment screw 6. Eccentricity dial 7, spacing dial 8, scale pointer 9, positioning pin hole 10, mounting hole 11, sealing ring groove 12, tooth surface 13, probe mounting hole 14, probe through hole 15, through hole 16, center Through hole 17, step one 18, step two 19.

[0018] Such as figure 2 , image 3 As shown, four installation holes 11 for fixed connection with the ultrasonic flaw detector are evenly distributed in the circumferential direction of the fixed seat 1, and a through hole 16 is also provided on the fixed seat 1; Figure 4 As shown, the bottom of the through hole 16 is provided with an annular step-18, and the through hole 16 is rotated and fitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com