Universal sounding lead device

A sounding hammer and universal technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of long strip sounding hammer stuck in bending, unable to complete detection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

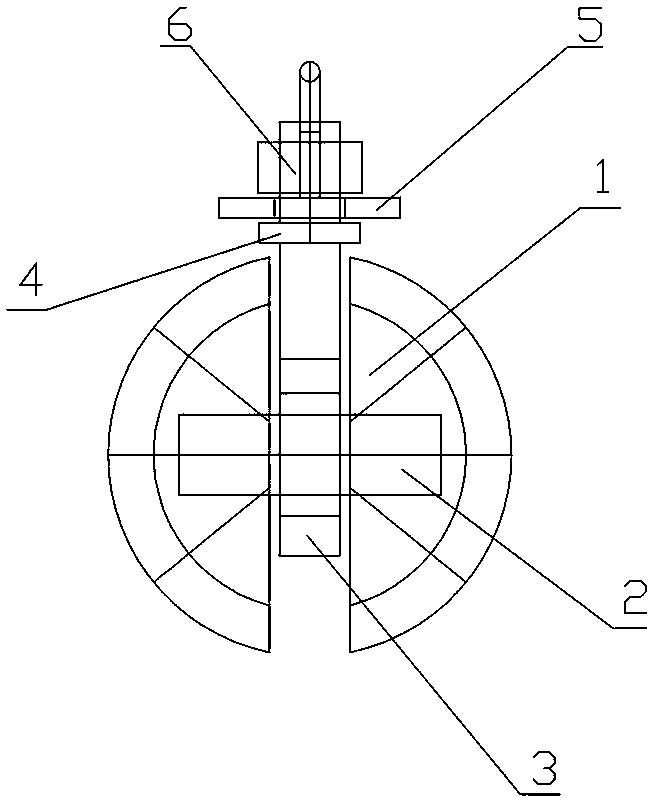

[0007] Such as figure 1 The universal sounding hammer device shown includes a rolling ball 1, which is formed by connecting two hemispheres through a middle shaft 2, and a rotating rod 3 is provided in the gap between the two hemispheres. The bottom end of the rotary rod is provided with an annular through hole, the middle rotating shaft between the two hemispheres runs through the annular through hole at the bottom end of the rotary rod, the top of the rotary rod is provided with a limit block 4, and the surface of the rotary rod above the limit block 4 is provided with threads. The suspension part 5 is sleeved on the top of the rotating rod through the through hole, and the positioning nut 6 is fixed on the top of the rotating rod by tightening the suspension part between the positioning nut and the limit block. The rotating rod on the universal sounding hammer device can swing around the middle shaft of the rolling ball to realize the forward and backward movement of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com