Driving device for safety belt tensioner

A technology for driving devices and safety belts, which is applied in the direction of transmission devices, seat belts in vehicles, belt tighteners, etc., can solve the problems of damage to mechanical properties of meshing components, large meshing force, deformation of meshing components, etc., and achieve a simple and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] exist figure 1 In the figure, only the main part of the seat belt tensioning drive device 1 in the device of the present invention is shown, wherein the motor 3 is used as the drive unit. The motor shaft 4 is connected with the main shaft 13 of the worm gear 10 through the transmission device 5, and can tension the winding shaft 4, so that the safety belt 2 is tightly wound around the winding shaft 4. The transmission device 5 is designed as a worm drive, which is composed of a worm 6 mounted on the motor shaft 4 of the motor 3 in a non-rotational connection and a worm wheel 7 matched with the worm 6, wherein the worm wheel 7 is fixedly installed on the main shaft 13 of the worm drive 10 superior. The housing of the belt tensioning drive is in the figure 1 is not shown in .

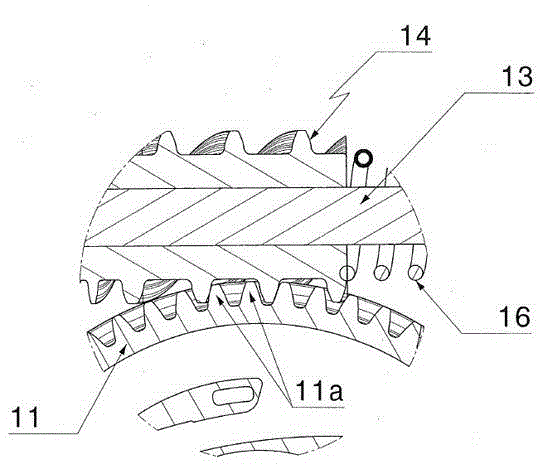

[0048] The worm drive 10 according to the invention comprises a worm 12 and a driven wheel 11 . The worm 12 is installed on the main shaft 13 and can move in the direction of R under the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com