Composite reinforcing method for grotto roof peeling defects of sandstone grotto

A technology for sandstone and grottoes, which is applied in the field of composite reinforcement of sandstone grotto roof peeling disease, can solve the problems of sandstone grotto surface information damage, sandstone grotto surface spalling disease aggravation, sandstone grotto dynamic damage, etc., to solve the new flaky spalling disease , small appearance effect, large anchoring force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings and preferred embodiments.

[0034] A composite reinforcement method for spalling disease of the roof of sandstone grottoes, characterized in that the steps are as follows:

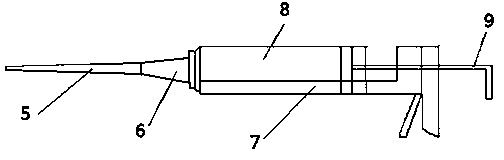

[0035] (1) A miniature portable non-vibration electric drill is used for drilling, and the drilling is controlled by adjusting the speed according to the hardness and softness of the sandstone; the drill pipe adopts a full-length threaded steel drill pipe, and the diameter can be set according to the characteristics of the exfoliation disease: ; Drill a hole deep grouting hole;

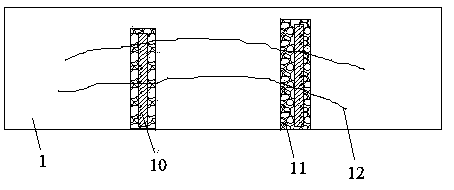

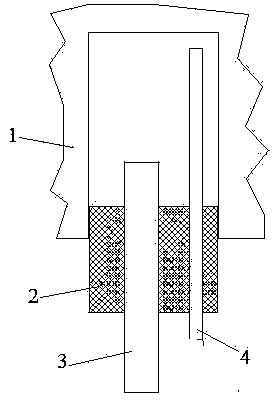

[0036] (2) if figure 1 As shown, the micro-bolt 10 (that is, the diameter is steel anchor rod or anti-corrosion bamboo anchor rod) placed in the drilled grouting hole, and positioned with a small bracket to ensure that there is a certain protective layer between the core material and the hole wall;

[0037] (3) Set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com