A glass fiber reinforced gypsum board interior wall dry bonded structure and its construction method

A technology of glass fiber and construction method, which is applied in the direction of building structure, covering/lining, construction, etc. It can solve the problems of reducing construction speed, large dust on the construction site, and difficulty in ensuring structural safety, so as to ensure structural strength and reduce on-site dust , Increase the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

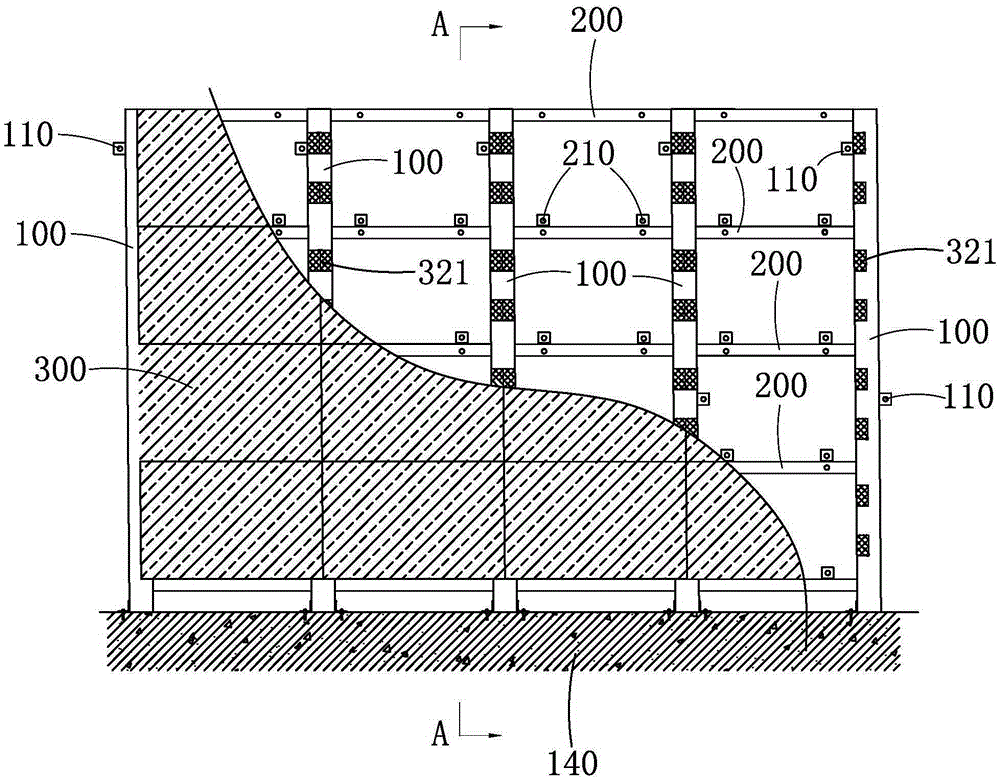

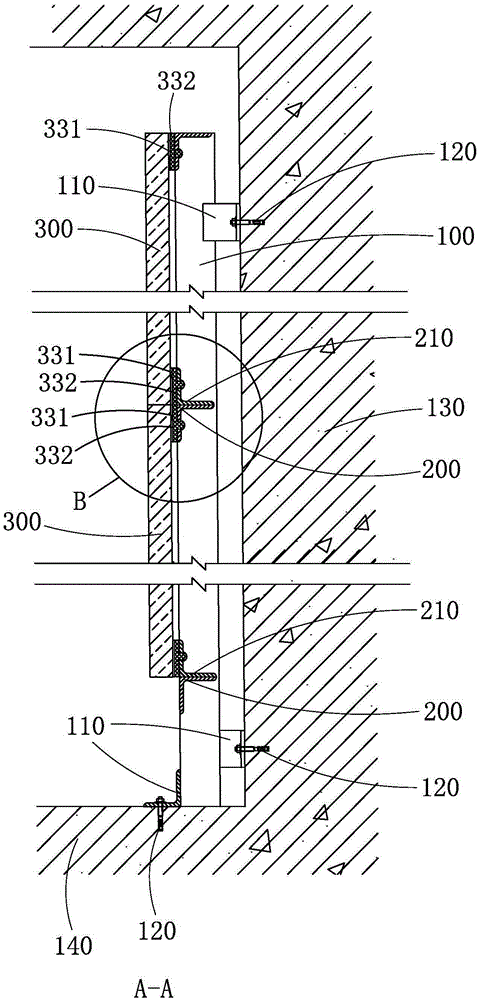

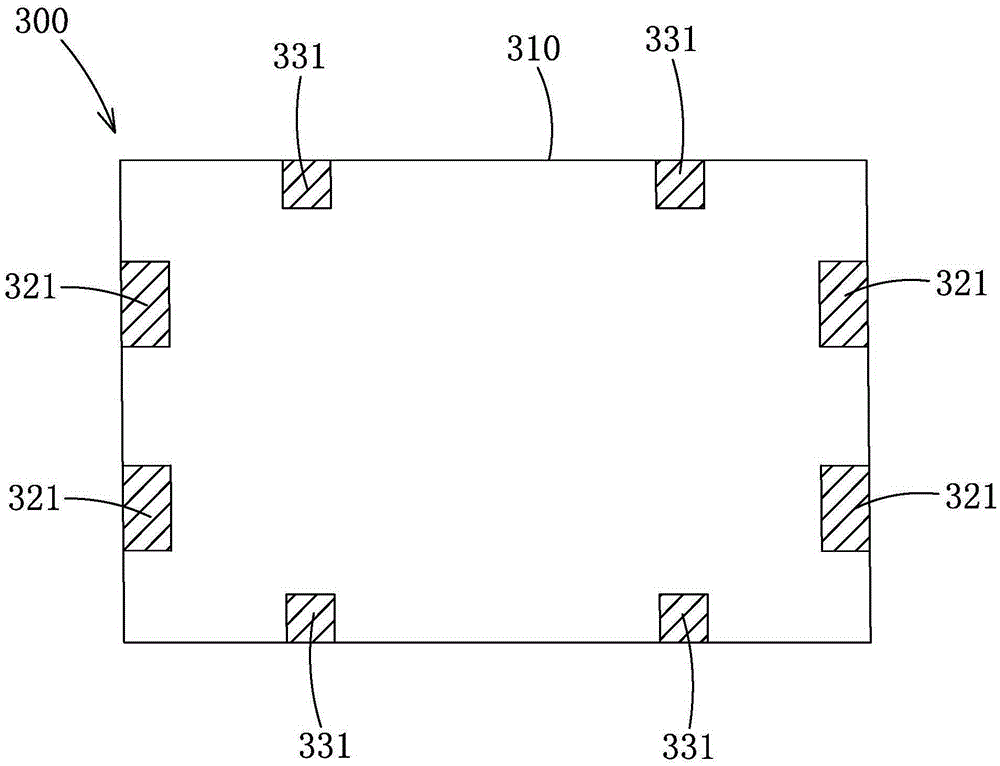

[0036] Such as figure 1 Shown is the front partial sectional view of the interior wall dry bonded structure of the glass fiber reinforced gypsum board of the present invention, comprising a glass fiber reinforced gypsum board 300, a plurality of steel columns 100 (preferably channel steel) vertically fixed to the interior wall 130 and Angle steel beam 200. The present invention makes improvements to the glass fiber reinforced gypsum board 300, such as Figure 4 with Figure 7 As shown, it includes a rectangular frame 310, a transverse rib 320, a longitudinal rib 330, a marble glue bonding convex plate 321, and a structural glue bonding convex plate 331, and the rectangular frame 310 is along the glass fiber reinforced gypsum board 300 edges are set, 2 (the number is not restricted, preferably 2) transverse ribs 320 are horizontally fixed between the longitudinal sides of the rectangular frame 310, and 2 (the number is not restricted, preferably 2) longitudinal ribs 330 are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com