Coaxial electromagnetic compensating tensioner

A tensioner and electromagnetic force technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of poor consistency and uniformity of weft yarn tension, difficult promotion, complex structure, etc., to improve consistency and uniformity, The prospect of large market demand and the effect of high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

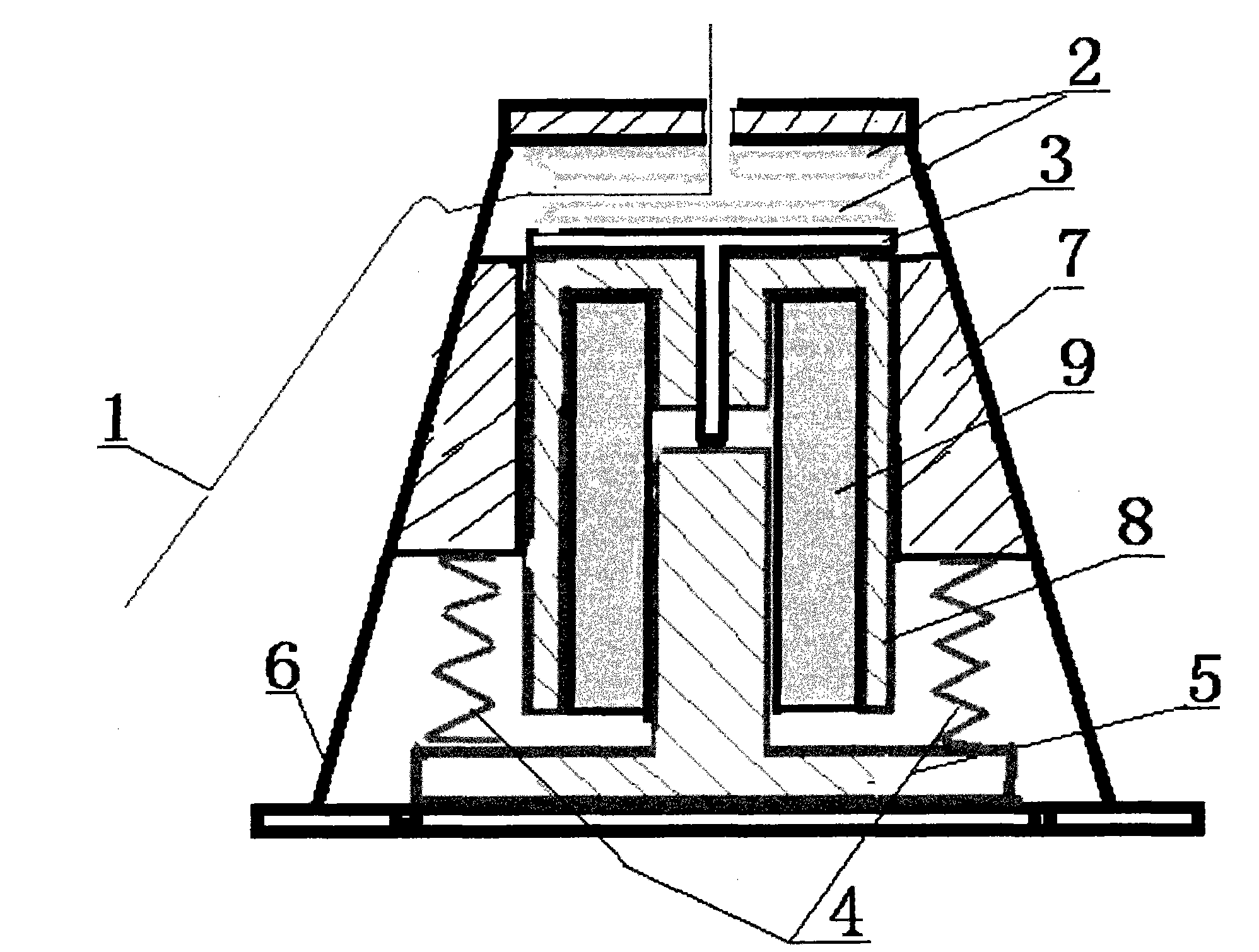

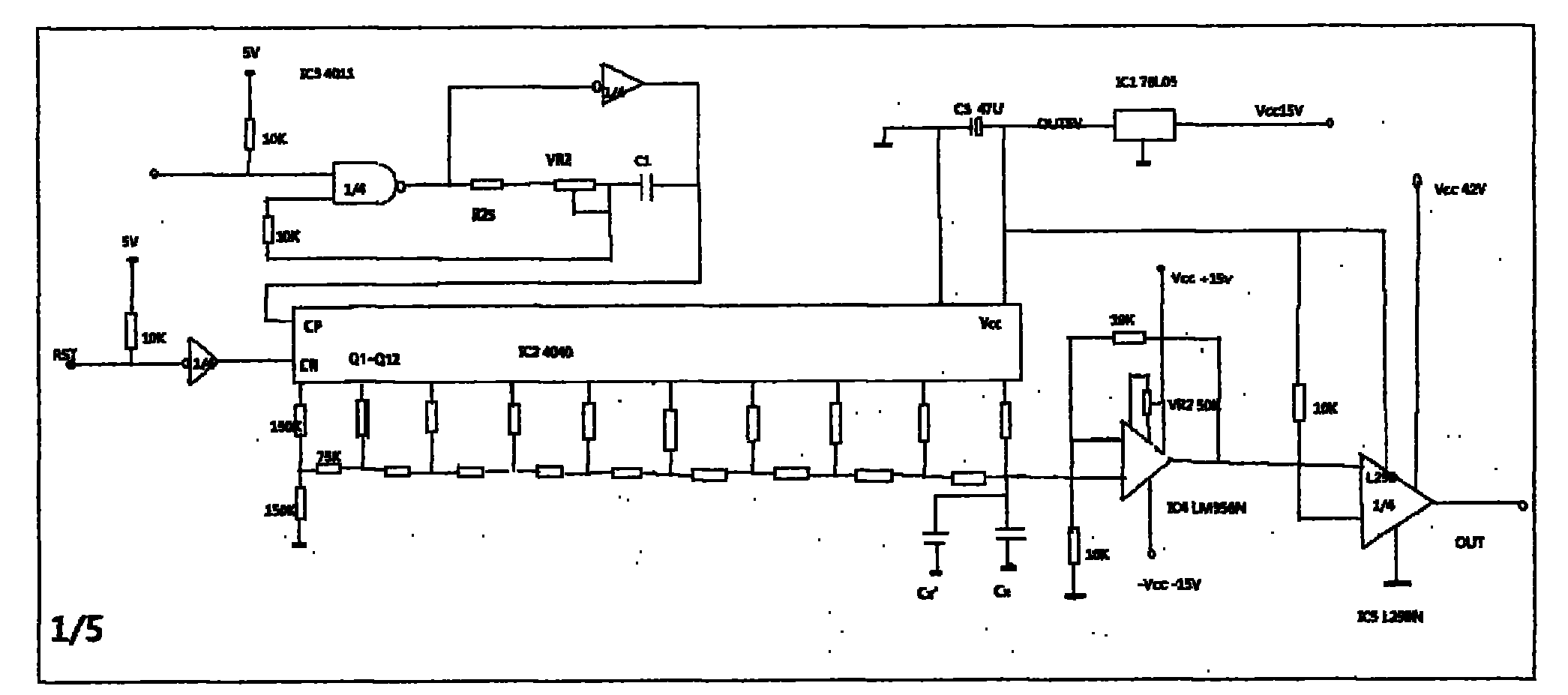

[0033] As shown in the figure, the coaxial electromagnetic compensation tensioner of the present invention uses electromagnetic force and spring force to jointly control the clamping force of the ceramic tension clamp on the yarn. The electromagnetic force is a time sequence of changing the strength of the electromagnetic force by changing the waveform of the current passing through the electromagnetic coil. Specifically, by changing the current waveform of the electromagnetic coil, it outputs multi-speeds synchronized with the weaving speed and compensates for the clamping force of the yarn holder for various weft insertion characteristics.

[0034] The electromagnetic force is equipped with a preset multi-level electromagnetic simulation tension complementary controller that adapts to different fabrics and weft insertion characteristics or the electromagnetic force is equipped with a preset multi-level electromagnetic simulation tension that adapts to different fabrics and weft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com