Conductive coating composition and display device including the same

一种导电涂料、显示装置的技术,应用在导电涂料、分散在不导电无机材料中的导电材料、涂层等方向,能够解决误操作、无法感测出电容的变化、无法识别触摸等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

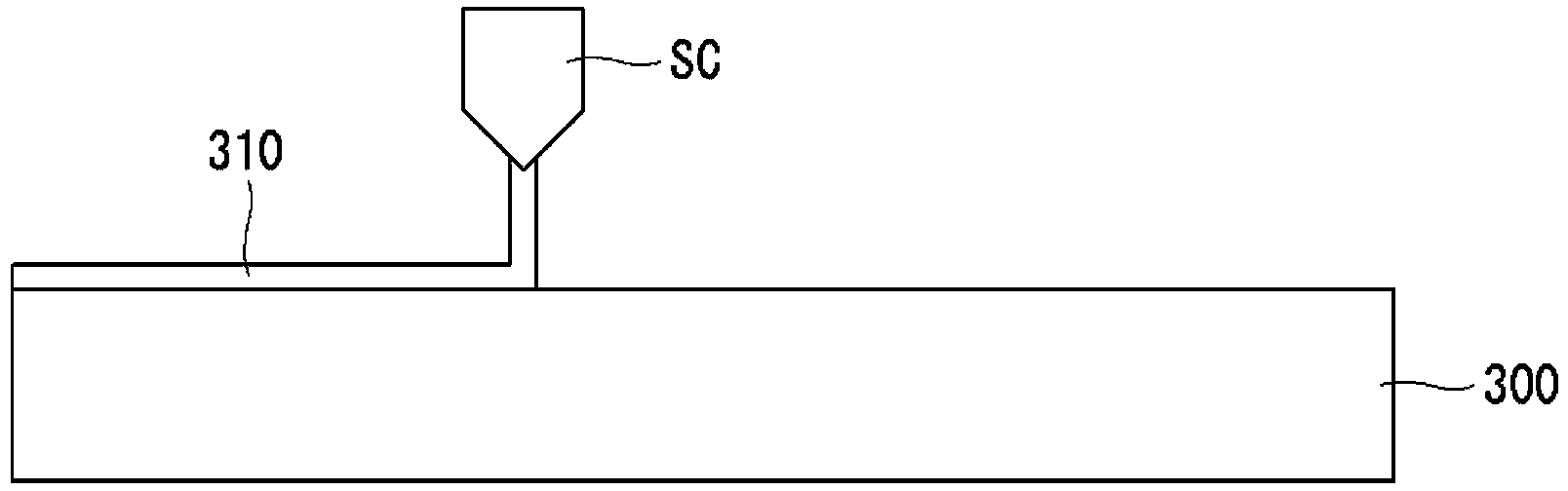

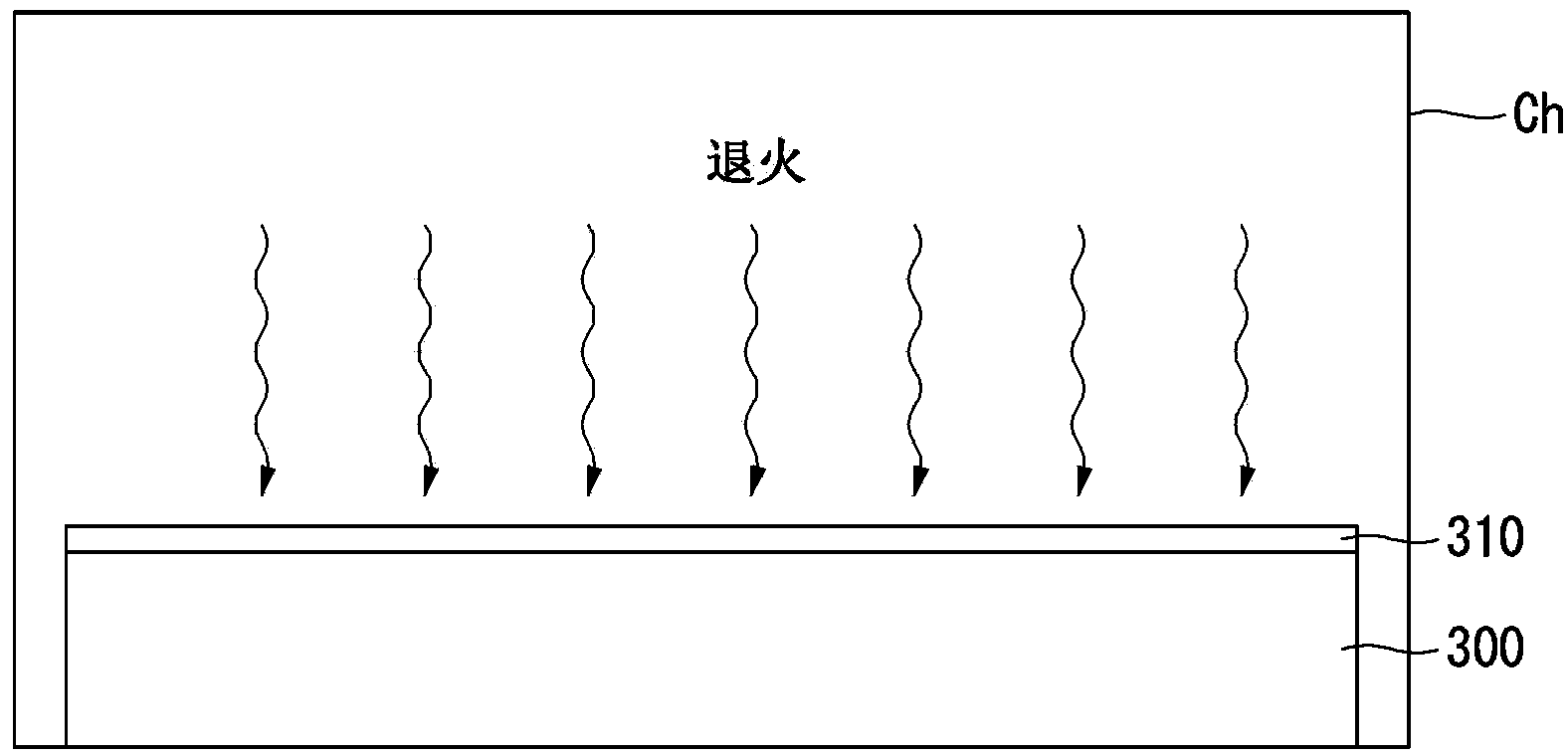

[0057]0.6 g of PEDOT:PSS solution and 15 g of polysilazane solution were added to a solvent containing a mixture of 39.4 g of water, 5 g of acetylacetone, 20 g of isopropanol, and 20 g of propylene glycol methyl ether to make a composition. The resulting composition was stirred for about 24 hours to well disperse the PEDOT:PSS and polysilazane in the solvent. Next, the prepared composition was loaded into a slit coater, and then coated on a glass substrate. Thereafter, the glass substrate was annealed in a chamber at a temperature of 140° C. for about 10 minutes, thereby removing the solvent. Accordingly, a back electrode formed of PEDOT:PSS and polysilazane was formed on the glass substrate.

[0058] The water vapor permeability WVTR of the as-prepared back electrodes over time was measured and shown in image 3 middle. In addition, the surface resistance of the back electrode over time under high temperature conditions of 80°C was measured and shown in Figure 4 middle. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com