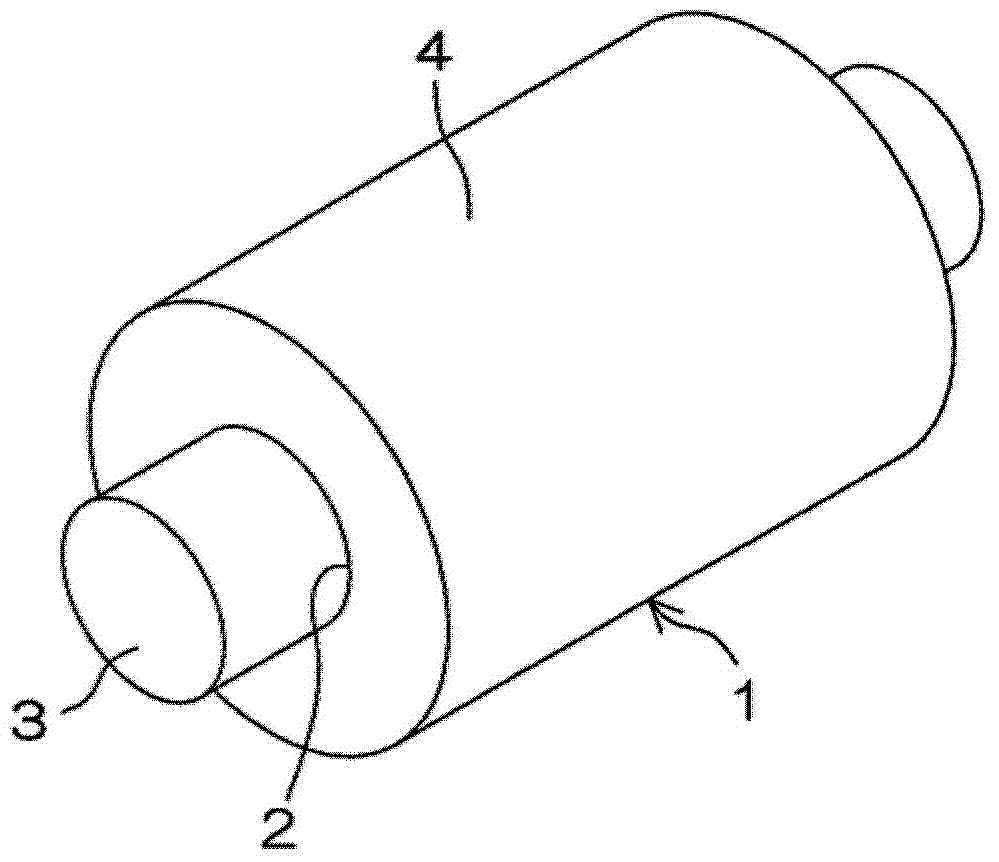

Rubber composition, paper feed roller, and image forming device

A rubber composition and rubber technology, which are applied in the direction of electric recording process applying charge pattern, equipment and object supply, etc. problem, to achieve the effect of small permanent elongation and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] (Preparation of rubber composition)

[0121] As the rubber component, 30 parts by mass of high-ethylene EPDM [NORDEL (NODERU, registered trademark) IP4770R manufactured by Dow Chemical Company, ethylene content: 70%, diene content: 4.9%] and 70 parts by mass of low-ethylene EPDM [ ESPRENE (registered trademark) 505A manufactured by Sumitomo Chemical Co., Ltd., ethylene content: 50%, diene content: 9.5%].

[0122] The ratio of high ethylene EPDM is 30% by mass in the total amount of rubber components. These two types of EPDM were further blended with the components shown in Table 1 below, and kneaded to prepare a rubber composition.

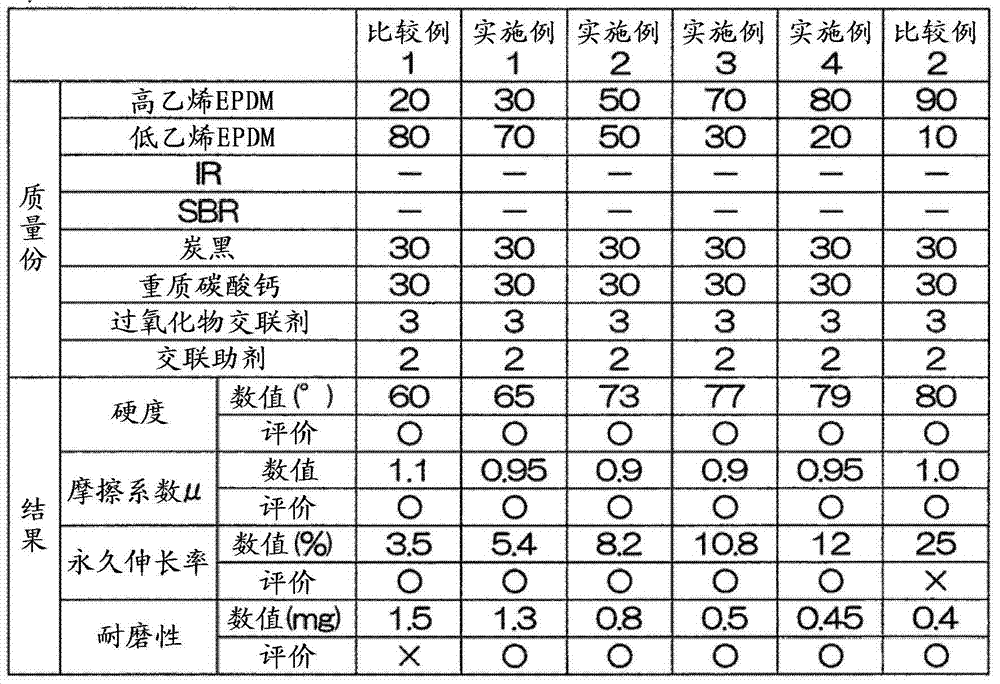

[0123] 【Table 1】

[0124] Table 1

[0125] Element

parts by mass

30

30

peroxide crosslinking agent

3

Crosslinking Auxiliary

2

[0126] The ingredients in Table 1 are as follows:

[0127] Carbon black: HAF, filler, trade name SEAST 3 manufact...

Embodiment 2

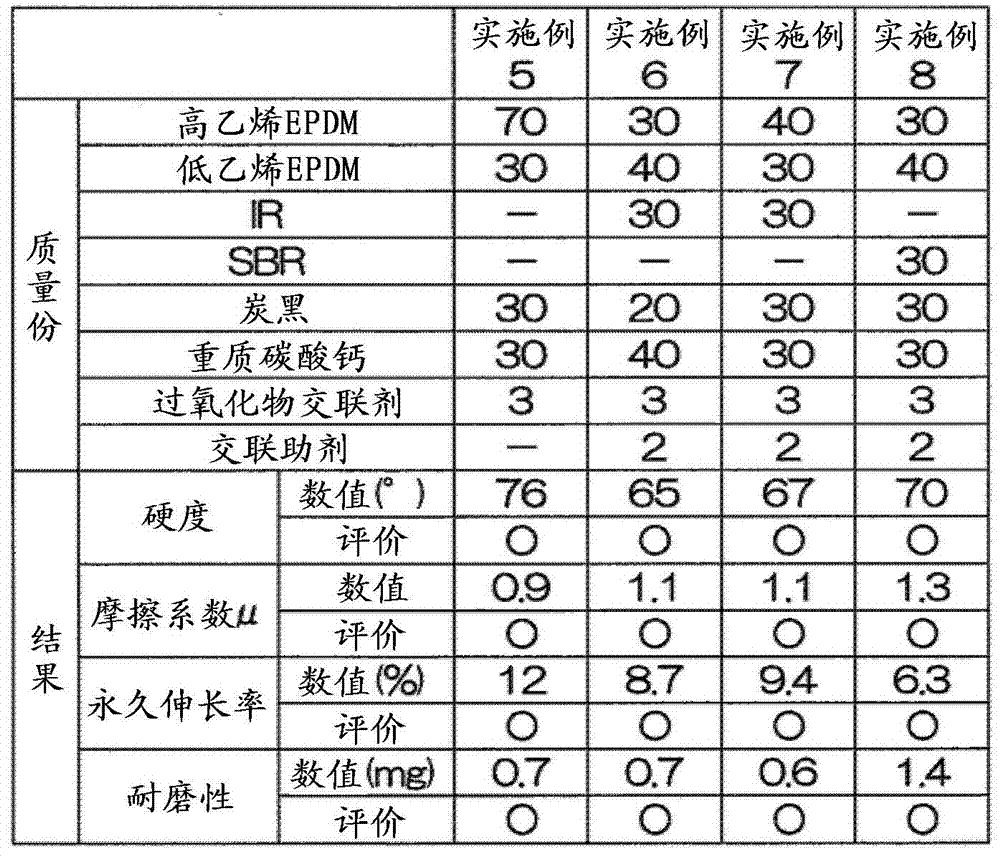

[0135] Except that the amount of high-ethylene EPDM was 50 parts by mass and the amount of low-ethylene EPDM was 50 parts by mass, a rubber composition was prepared in the same manner as in Example 1, and a paper feed roller 1 was manufactured.

[0136] The ratio of high ethylene EPDM is 50% by mass in the total amount of rubber components.

Embodiment 3

[0138] Except that the amount of high-ethylene EPDM was 70 parts by mass and the amount of low-ethylene EPDM was 30 parts by mass, a rubber composition was prepared in the same manner as in Example 1, and a paper feed roller 1 was manufactured.

[0139] The ratio of high ethylene EPDM is 70% by mass of the total amount of rubber components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com