Manufacturing method for double-layer holographic anti-counterfeiting film

A kind of technology of holographic anti-counterfeiting and production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

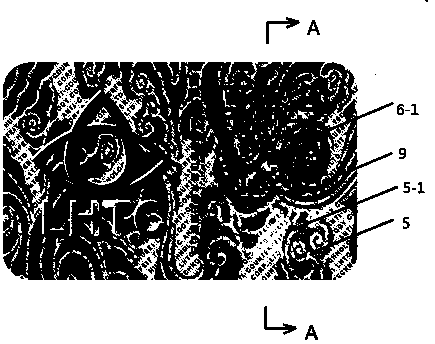

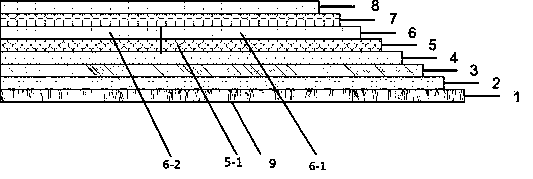

[0027] Embodiment 1: A method for making a double-layer holographic anti-counterfeiting film, such as figure 2 As shown, the specific steps are:

[0028] The first step: making a separation layer 2 on the PET base film 1;

[0029] Second step: coating the imaging layer 3 on the separation layer 2;

[0030] The third step: molding the holographic image to make the laser information layer 4;

[0031] Step 4: Partially spray and print a two-dimensional code 6-1 on the laser information layer 4, the code printing of the two-dimensional code 6-1 on the laser information layer 4 is precisely positioned and printed at a specific position; the laser The two-dimensional code 6-1 on the information layer 4 is a logic editing variable two-dimensional code, and each two-dimensional code 6-1 is unique, forming a two-dimensional code layer; the two-dimensional code 6-1 of the spray printing is A logically edited two-dimensional code 6-1, which can represent characters in multiple langua...

Embodiment 2

[0045] A method for making a double-layer holographic anti-counterfeiting film, the specific steps are as follows: figure 2 as shown,

[0046] The first step: making a separation layer 2 on the PET base film 1;

[0047] Second step: coating the imaging layer 3 on the separation layer 2;

[0048] The third step: molding the holographic image to make the laser information layer 4;

[0049] Step 4: Partially spray and print a two-dimensional code 6-1 on the laser information layer 4, the code printing of the two-dimensional code 6-1 on the laser information layer 4 is precisely positioned and printed at a specific position; the laser The two-dimensional code 6-1 on the information layer 4 is a logically editable variable two-dimensional code 6-1. The two-dimensional code 6-1 implicitly contains a number corresponding to the digital code, and each two-dimensional code is unique. Constitute the two-dimensional code layer 6-1;

[0050] Step 5: Coating random holographic color s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com