Fixed abrasive wire saw and method of making the same

An abrasive and wire saw technology, applied in the field of fixed abrasive wire saw and its preparation, can solve the problems of reduced bonding strength, clogging of chips, etc., and achieve the effects of not falling off easily, prolonging service life, and improving cutting flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

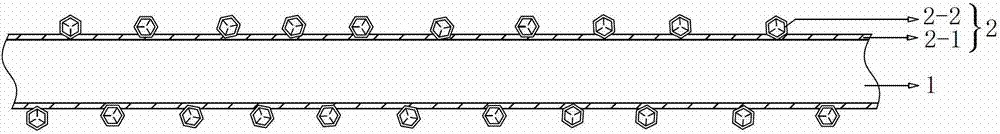

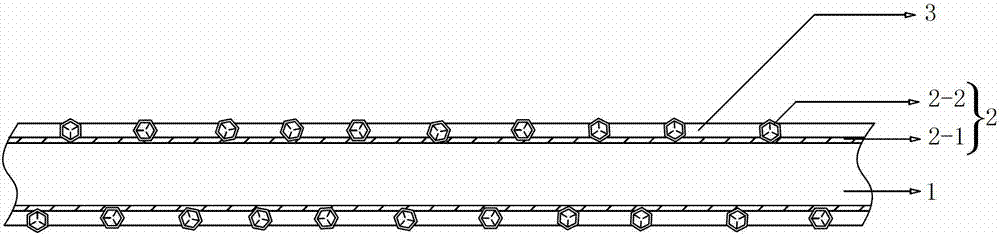

[0059] like figure 2 The first specific embodiment of the fixed abrasive wire saw shown in the present invention includes a wire 1, which is a copper-plated steel wire; a bonding layer 2 is formed on the surface of the wire 1, and the bonding layer 2 includes The electroplating layer 2-1 on the surface and several abrasive particles 2-2 embedded and fixed in the electroplating layer, the material of the electroplating layer is zinc, and the abrasive particles are diamond outer layer completely wrapped in the metal compound layer, the main body of the metal compound layer The material is copper-chromium alloy; and the surface layer 3, the surface layer 3 is one layer, the surface layer 3 covers the surface of the bonding layer 2, and the material of the surface layer 3 is epoxy resin.

[0060] like figure 1 and 2 As shown, the preparation method of the abrasive particles in the first embodiment of the fixed abrasive wire saw of the present invention is:

[0061] 1) The orga...

Embodiment 2

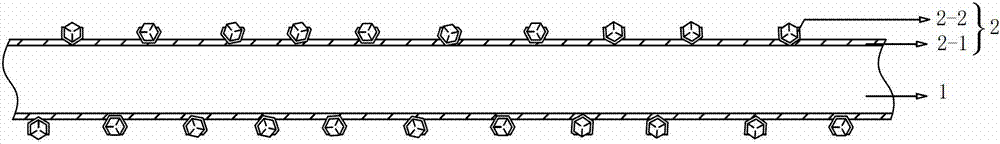

[0071] like Figure 4 The second specific embodiment of the fixed abrasive wire saw of the present invention shown includes a wire 1, and the wire 1 is a stainless steel wire; a bonding layer 2 is formed on the surface of the wire 1, and the bonding layer 2 includes a The electroplating layer 2-1 and several abrasive particles 2-2 embedded and fixed in the electroplating layer, the material of the electroplating layer is a tin-copper alloy, the abrasive particles are a silicon carbide outer layer partially wrapped with a metal compound layer, and the metal compound layer The main material is copper-nickel alloy; and the surface layer 3, the surface layer 3 is one layer, the surface layer 3 covers the surface of the bonding layer 2, the material of the surface layer 3 is epoxy resin, and the epoxy resin is filled with filler abrasives 3-1 carbonization silicon. The outer surface of the surface layer 3 is formed with grooves 3-2.

[0072] like image 3 and 4 As shown, the pr...

Embodiment 3

[0083] like Image 6 The third specific embodiment of the fixed abrasive wire saw shown in the present invention includes a wire 1, which is a copper-plated steel wire; a bonding layer 2 is formed on the surface of the wire 1, and the bonding layer 2 includes a The electroplating layer 2-1 on the surface and several abrasive particles 2-2 embedded and fixed in the electroplating layer, the material of the electroplating layer is nickel-copper alloy, and the abrasive particles are bare silicon carbide particles. The abrasive particles in this embodiment are also It can be diamond, cubic boron nitride, aluminum oxide or a combination thereof; and a surface layer 3, the surface layer 3 is one layer, the surface layer 3 covers the surface of the bonding layer 2, the material of the surface layer 3 is nickel, and the nickel metal is filled with Filled abrasive 3-1, the filled abrasive 3-1 is a mixed filler of silicon carbide and graphite.

[0084] like Figure 5 and Image 6 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com