Antifreeze and heat utilization device and method for solar battery cooling liquid

A solar cell and cooling liquid technology, applied in photovoltaic power generation, electrical components, photovoltaic thermoelectric hybrid power generation, etc., can solve the problem of solar cell cooling liquid freezing, and achieve the effect of reducing energy consumption, saving energy and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

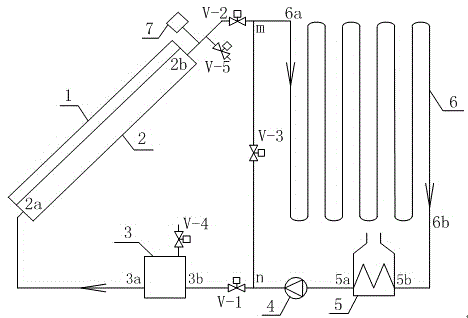

[0038] Take water as the cooling liquid as an example to further explain:

[0039] When the temperature probe 7 senses that the temperature in the solar cell cooler 2 is 32°C or greater than the heating temperature value of 26°C, it is set by the user, the electric valve V-2 and the electric valve V-1 are opened, and the electric valve V-3 is opened. , the exhaust valve V-4, and the exhaust valve V-5 are closed, the boiler 5 does not work, and the heat in the solar cell cooler 2 is independently circulated to form a low-grade heat utilization mode. If the temperature detected by the temperature probe 7 is higher than the solar cell power generation efficiency critical value of 35°C, increase the rotating speed of the working medium pump 4, increase the flow rate of the circulating working medium water in the device, and reduce the temperature at the outlet of the solar battery cooler 2;

[0040] When the temperature probe 7 detects that the temperature in the solar cell cooler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com