Device for preventing blast hole from freezing

A blast hole and lead block technology, which is applied in the field of equipment to prevent blast holes from freezing in blasting construction in plateau alpine regions, can solve the problems of not fundamentally solving the problem of blast hole freezing, failing to solve the problem of freezing, and increasing the labor load of workers. , to achieve the effect of solving blast hole freezing, simple structure, and small labor workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

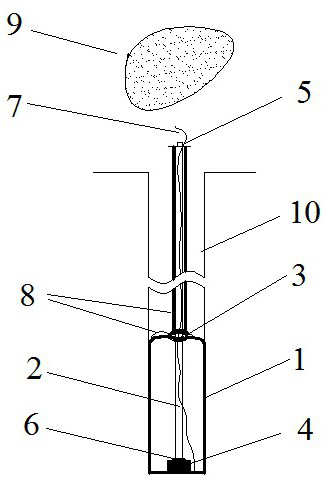

[0016] exist figure 1 , use three bolts to install and fix one end of the guide balance lead weight (4) and the safety rope (7) at the bottom of the closed barrel (1), and the inflation hose (2) is installed inside the closed barrel (1) to inflate One end of the hose (2) is connected to the inflatable connector (5), and the other end is connected to the magnetic connector (6). The magnetic connector (6) is connected to the guide balance lead weight (4). Outside the closed barrel (1), the damper (3) is installed outside the tightening bag (8) close to the guide balance lead weight (4) and at the position above it.

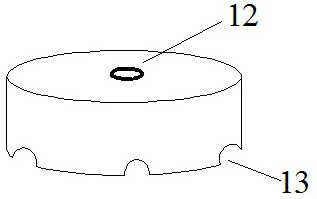

[0017] exist image 3 Among them, the installation direction of the air guide groove (13) is downward, that is, it is in contact with the bottom of the closed barrel (1).

[0018] exist Figure 4 Among them, the ring-shaped outer edge (11) is located on the inner side during installation, that is, on the side of the inflation hose (2), and mainly acts as a limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com