Miniaturization band elimination type frequency selective surface

A frequency-selective surface and band-stop technology, which is applied in waveguide devices, electrical components, circuits, etc., can solve the problems of high cost, complex design of frequency-selective surface unit structure, and difficult production, and achieve low cost and unit structure design. Easy, cell size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiment of a miniaturized band-stop frequency selective surface provided by the present invention will be described in detail below in conjunction with the accompanying drawings:

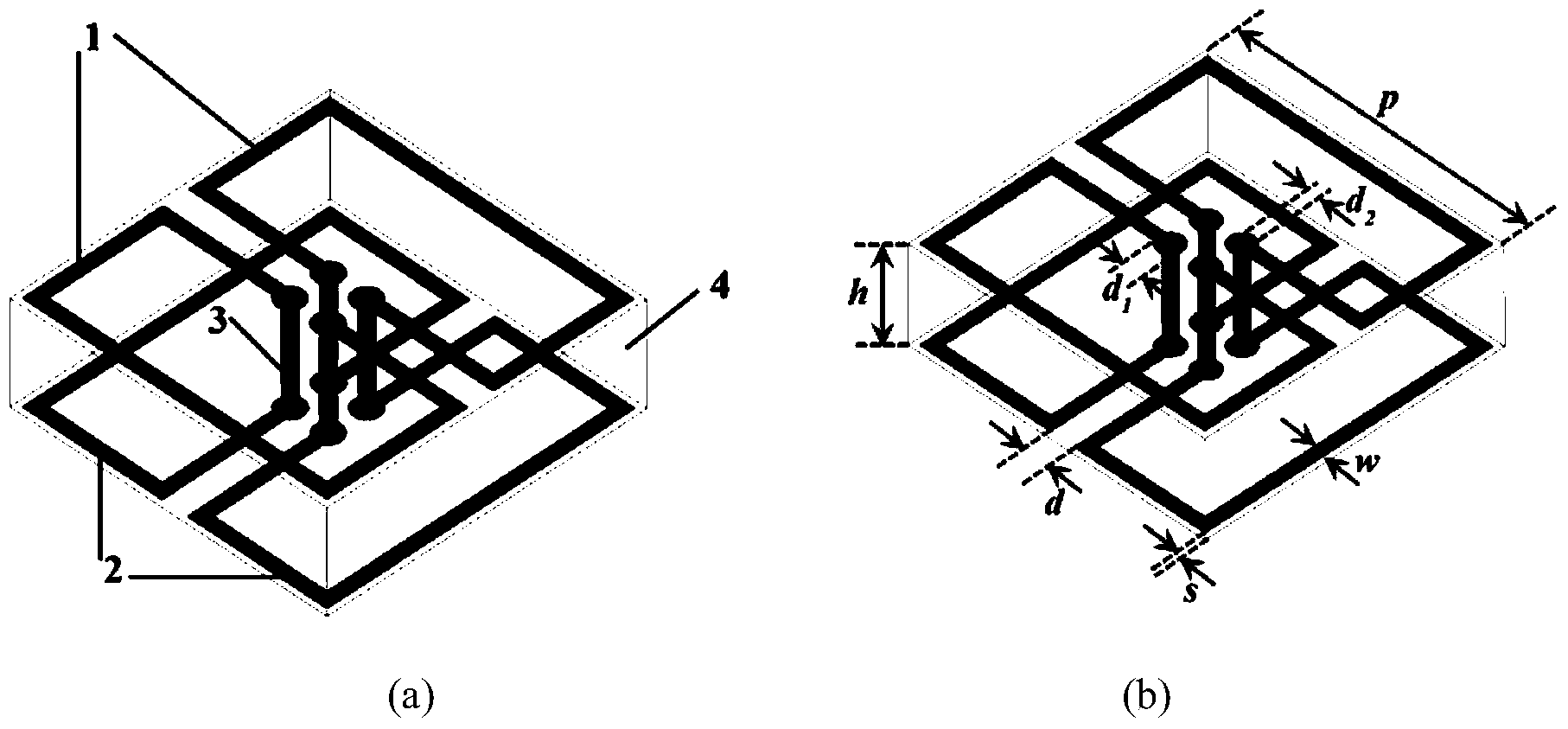

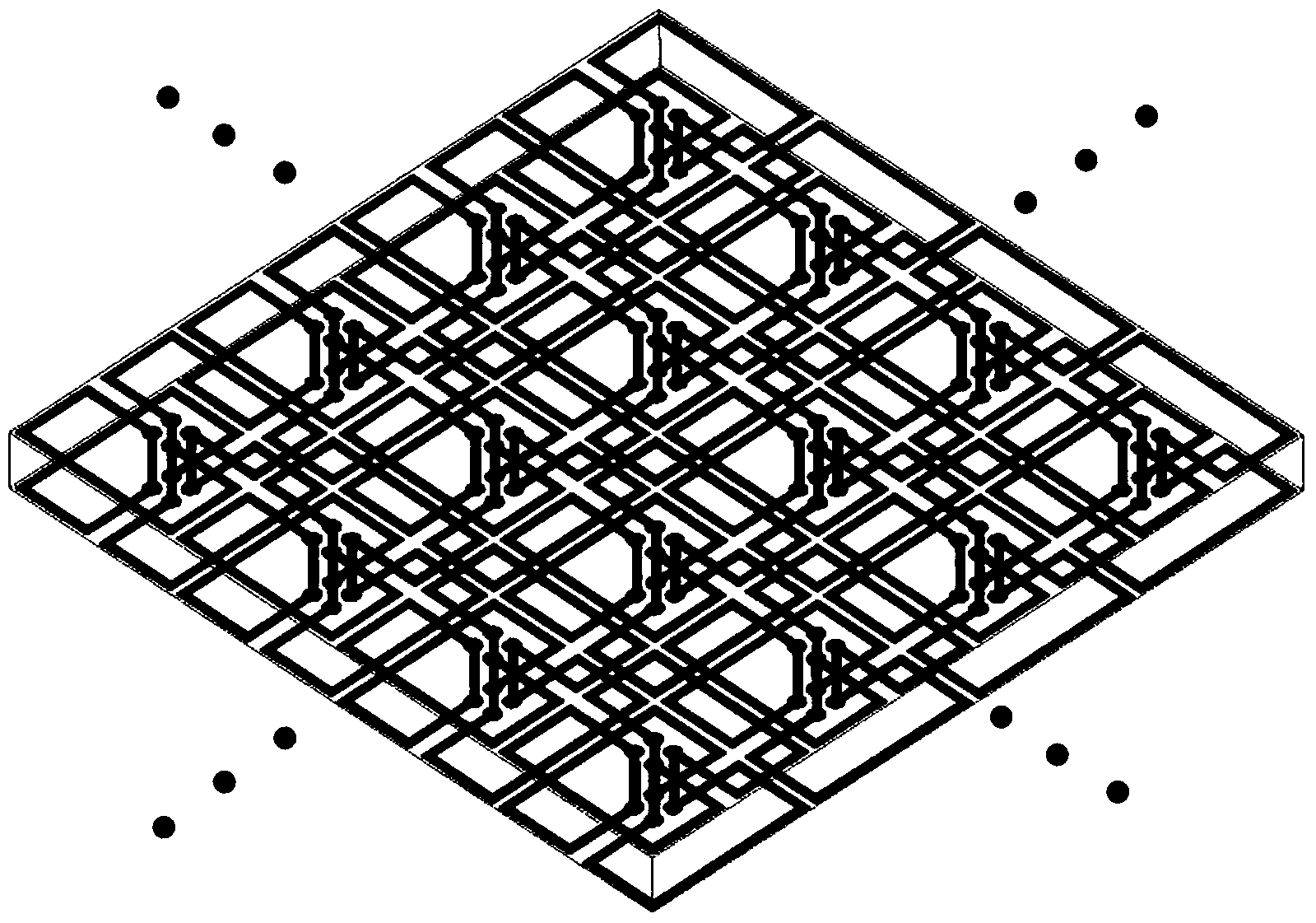

[0015] A unit of a miniaturized band-stop frequency selective surface designed by the present invention is as figure 1 As shown in (a), it includes a pair of rectangular open metal rings 1 on the upper surface of the dielectric substrate, a pair of rectangular open metal rings 2 on the lower surface of the dielectric substrate, and four metal through holes 3 connecting the opening ends of the rectangular metal rings on the upper and lower surfaces of the dielectric substrate. The opening directions of the rectangular metal rings are opposite, and the pair of rectangular metal rings on the lower surface are obtained by rotating the pair of rectangular metal rings on the upper surface by 90 degrees as a whole, and the metal thin wires of the four rectangular metal rings on the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com