Well-bore sulfur deposit visual experiment device and well-bore sulfur deposit visual experiment method

An experimental device, sulfur deposition technology, applied in the direction of analyzing materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

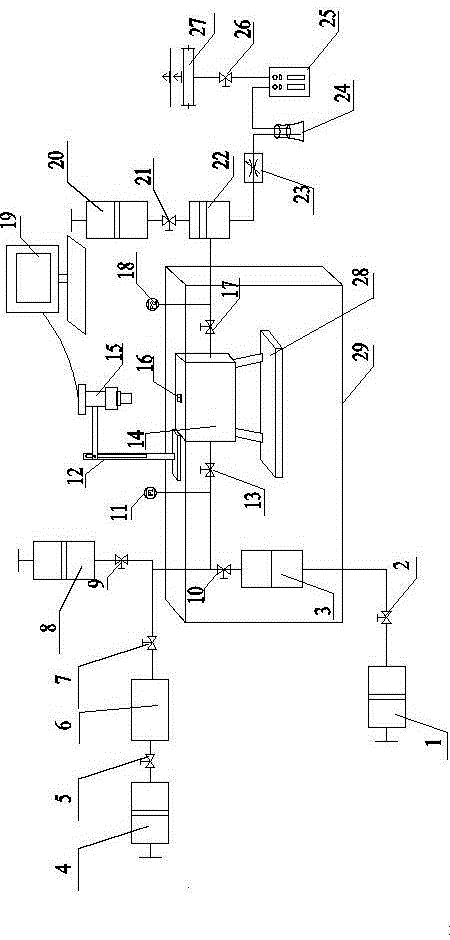

[0040] The microscopic visualization experiment method of wellbore sulfur deposition using the wellbore sulfur deposition visualization experiment device includes the following steps:

[0041] S1. Clean the intermediate container 3 and all its experimental pipelines with alcohol and petroleum ether;

[0042] S2. Because the temperature and pressure of the gas sample retrieved from the field have changed significantly compared with the formation conditions, the phase state of the gas sample has changed. It is necessary to re-match the sample in the sample dispenser 6 according to the original formation conditions. If necessary, inject a certain proportion of gas samples into the sample dispenser 6 according to the original formation conditions;

[0043] S3. Weigh 5g of elemental sulfur powder, put it into the intermediate container 3, and use the vacuum pump 8 to vacuum the intermediate container 3; then use the booster pump to pressurize the interior of the intermediate container 3; ...

Embodiment 2

[0052] The microscopic visualization experiment method of wellbore sulfur deposition using the wellbore sulfur deposition visualization experiment device includes the following steps:

[0053] S1. Clean the intermediate container 3 and all its experimental pipelines with alcohol and petroleum ether;

[0054] S2. Because the temperature and pressure of the gas sample retrieved from the field have changed significantly compared with the formation conditions, the phase state of the gas sample has changed. It is necessary to re-match the sample in the sample dispenser 6 according to the original formation conditions. If necessary, inject a certain proportion of gas samples into the sample dispenser 6 according to the original formation conditions;

[0055] S3. Weigh 5g of elemental sulfur powder, put it into the intermediate container 3, and use the vacuum pump 8 to vacuum the intermediate container 3; then use the booster pump to pressurize the interior of the intermediate container 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com