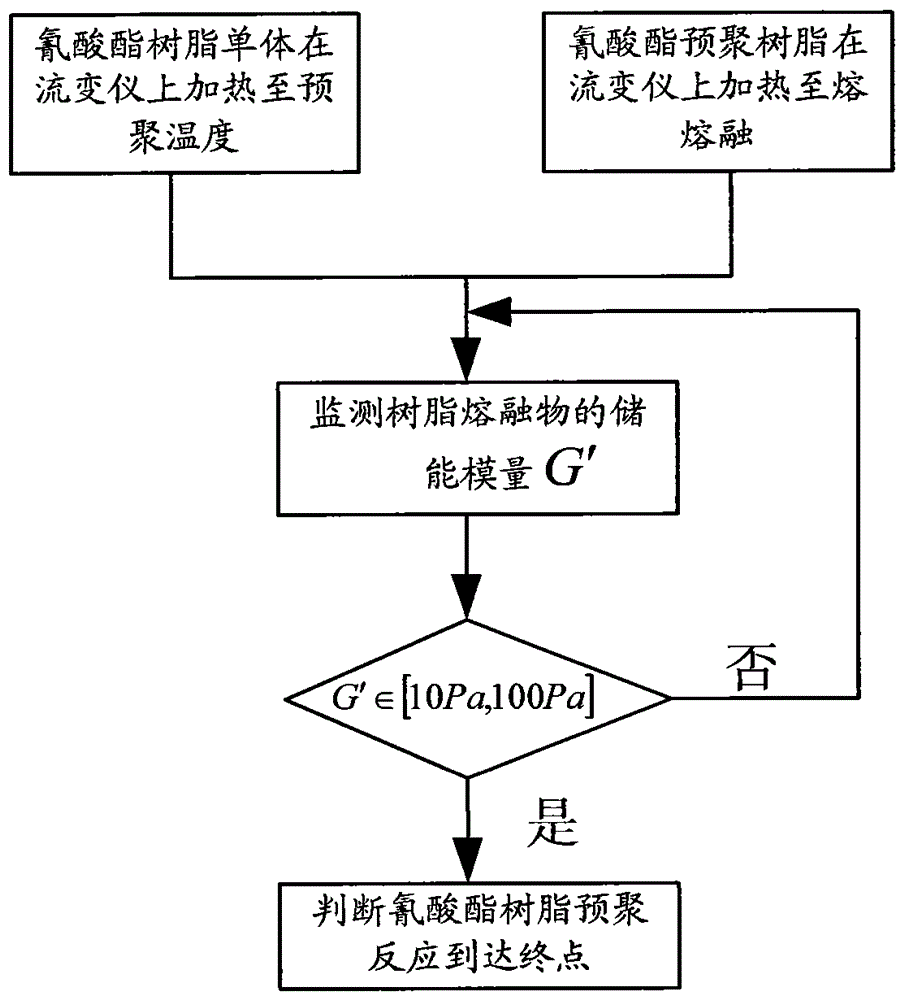

A method for determining the end point of cyanate resin prepolymerization

A technology of cyanate ester resin and reaction end point, applied in flow characteristics, measuring devices, instruments, etc., can solve problems such as untestable, unsuitable, difficult to uniform films, etc., to achieve industrial production monitoring, high precision, process Simple and Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

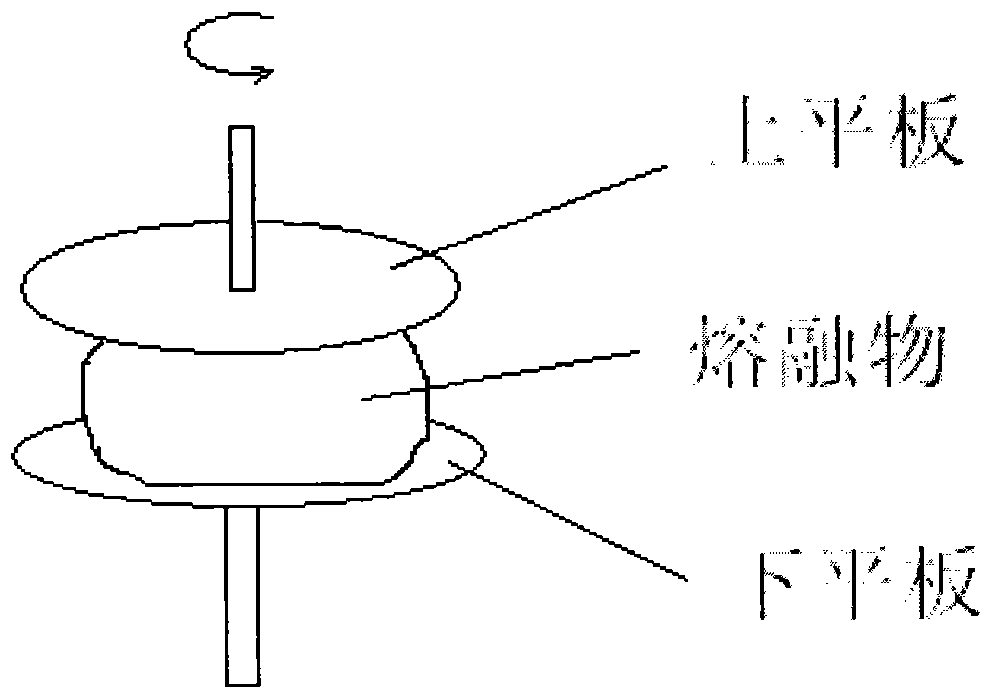

[0036] Add 0.2g of bisphenol A cyanate resin monomer to the center of the lower plate in the high-temperature plate rotational rheometer, raise the temperature to 100°C, the monomer material melts, and lower the upper plate of the rheometer to touch the molten single Object, under the conditions of torsion frequency (1Hz) and torsion force (1mN·m), the temperature of the plate is raised to the temperature of the polymerization reaction (180°C), and the timing is started. The storage modulus G' of the melt is measured by a rheometer, wherein the storage modulus G' is determined by 10 -4 When Pa rises to 100Pa, it can be judged that the prepolymerization reaction has reached a suitable level, and the time to reach this point is recorded as 195 minutes.

[0037] The parameters of cyanate resin prepolymerization reaction temperature (180°C) and time (195min) determined according to this example can be applied to the preparation of cyanate resin prepolymers, which can be transparen...

Embodiment 2

[0039] Take out 0.2 g of bisphenol A cyanate resin prepolymer that has been prepolymerized for a certain period of time from the reactor, add it to the center of the lower plate in the high-temperature plate rotary rheometer, and raise the temperature to 190 ° C. When the material melts, lower the upper plate of the rheometer to touch the molten material to a specified area, measure the storage modulus G' under the conditions of torsion frequency (0.5Hz) and torsion force (3mN·m), and start timing. The storage modulus G' of the melt is measured by a rheometer, and the storage modulus G' is determined by 10 -3 When Pa rises to 10Pa, it can be judged that the polymerization reaction has reached a suitable level, and the time to reach this point is recorded as 14 minutes.

[0040] The temperature (190°C) and time (14min) parameters of the cyanate ester resin prepolymerization determined according to this example are applied to the preparation of the prepolymerization resin, which c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com