System for on-line detection of winding deformation based on overvoltage signal and response of transformer

A winding deformation and detection system technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., to achieve the effects of easy installation, safe and stable operation, and convenient human control and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific embodiments.

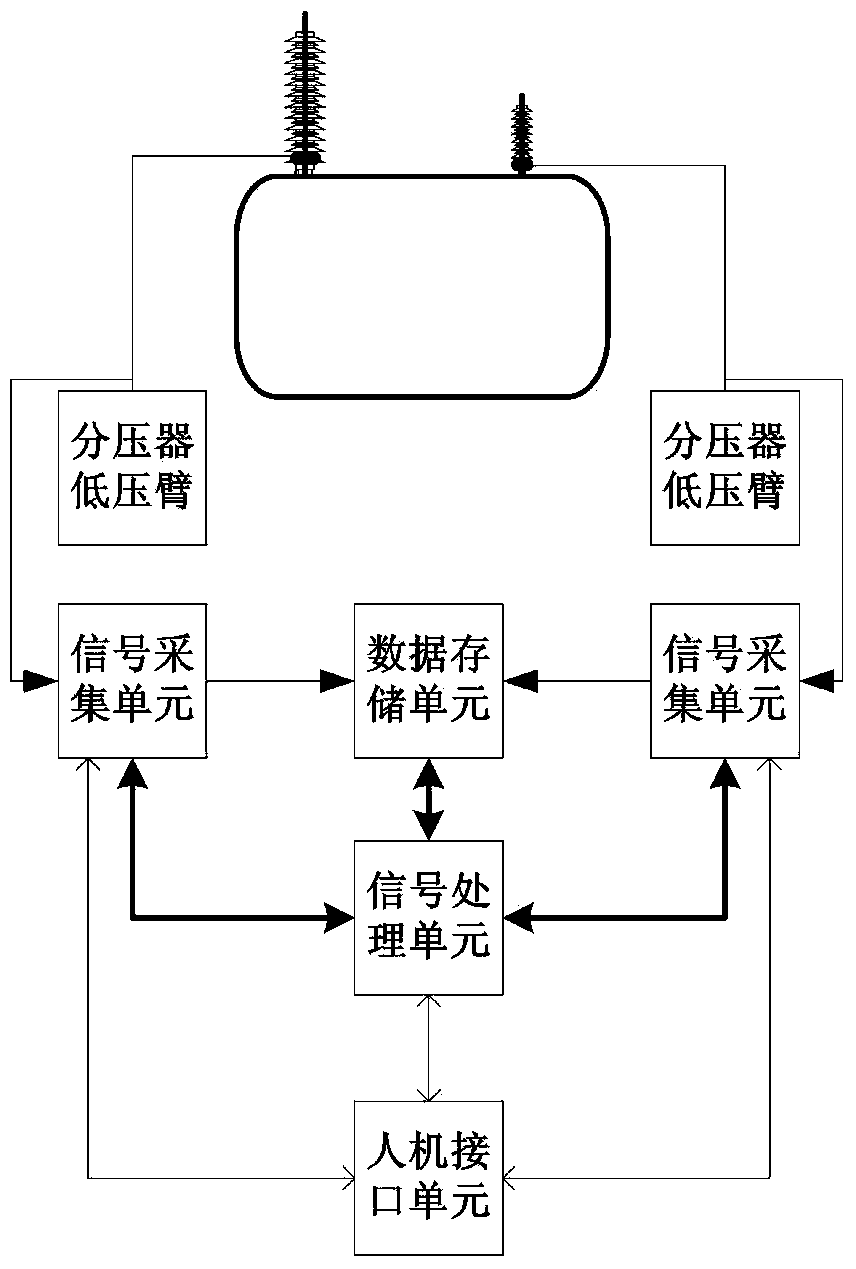

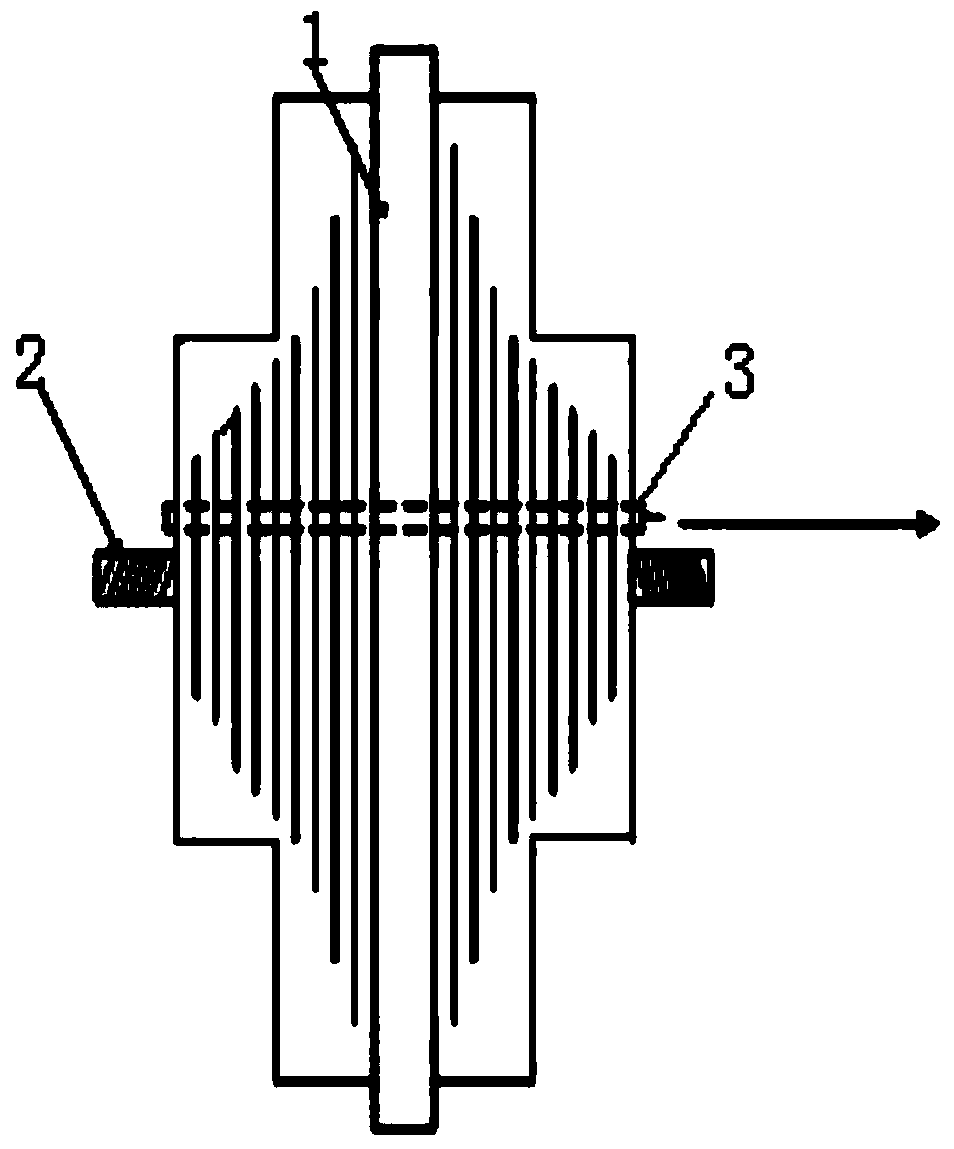

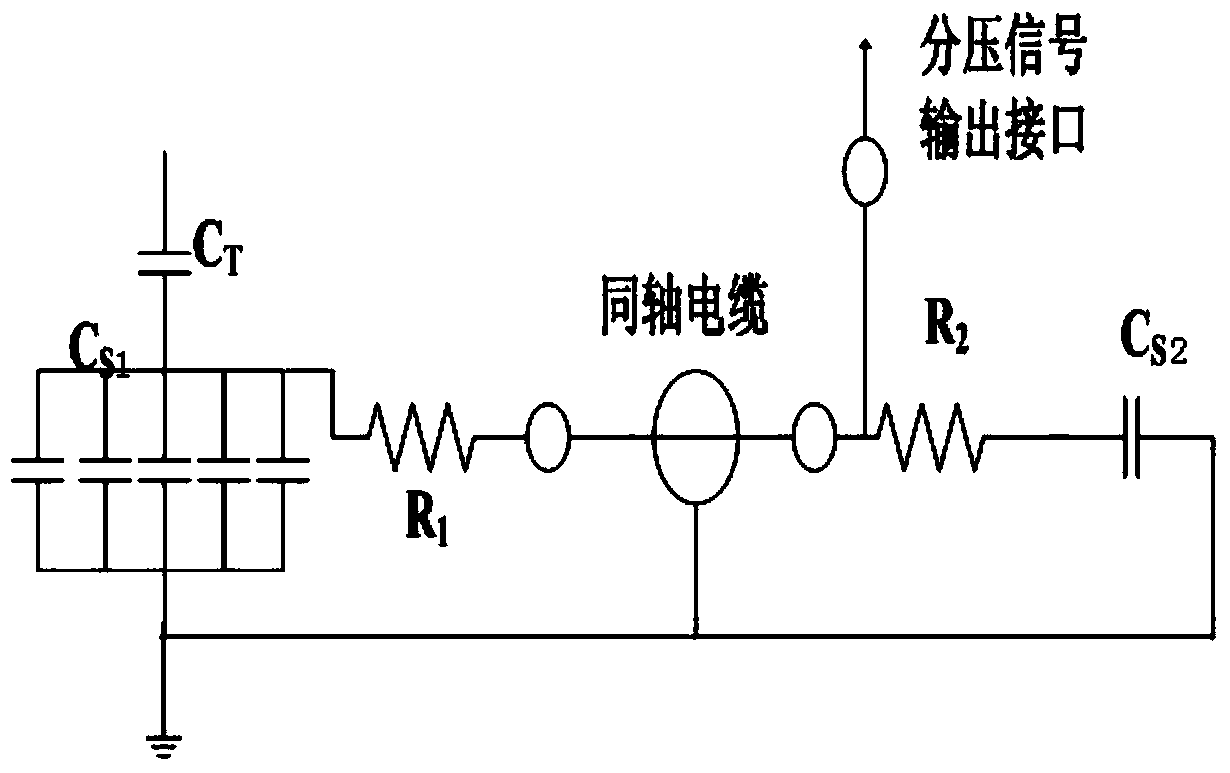

[0029] figure 1 It is a structural principle block diagram of the whole system of the present invention; figure 2 It is a schematic diagram of a transformer overvoltage capacitive coupling sensor of the present invention; image 3 It is a schematic diagram of the low voltage arm of the voltage divider and the matching part of the coupling voltage division unit in the present invention. according to figure 1 , 2 As shown in and 3, an online detection system for winding deformation based on transformer overvoltage signals and responses mainly includes a coupling voltage divider unit, a signal acquisition unit, a signal processing unit, a signal storage unit and a human-machine interface unit. The system can monitor the transformer winding deformation by monitoring the overvoltage signal online and analyzing its response without changing the existing wiring of the power system.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com