High-purity acetonitrile and method and device for preparing high-purity acetonitrile

A pure acetonitrile and acetonitrile technology, applied in the field of high-purity chemical reagents, can solve the problems of high impurity content of acetonitrile solvent, unsatisfactory purity, complicated preparation process, etc., and achieve the effects of low cost, simple operation, and simple device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

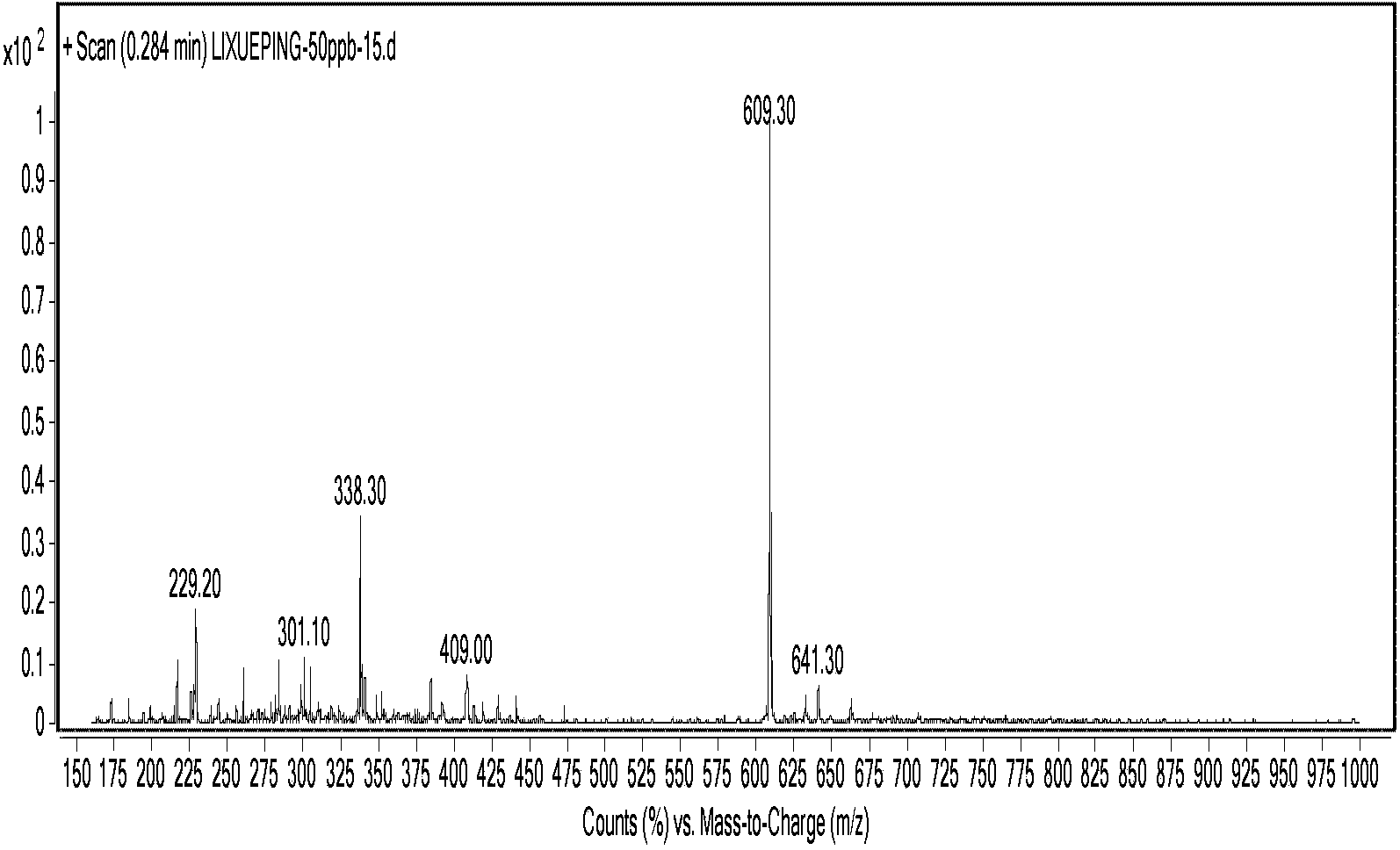

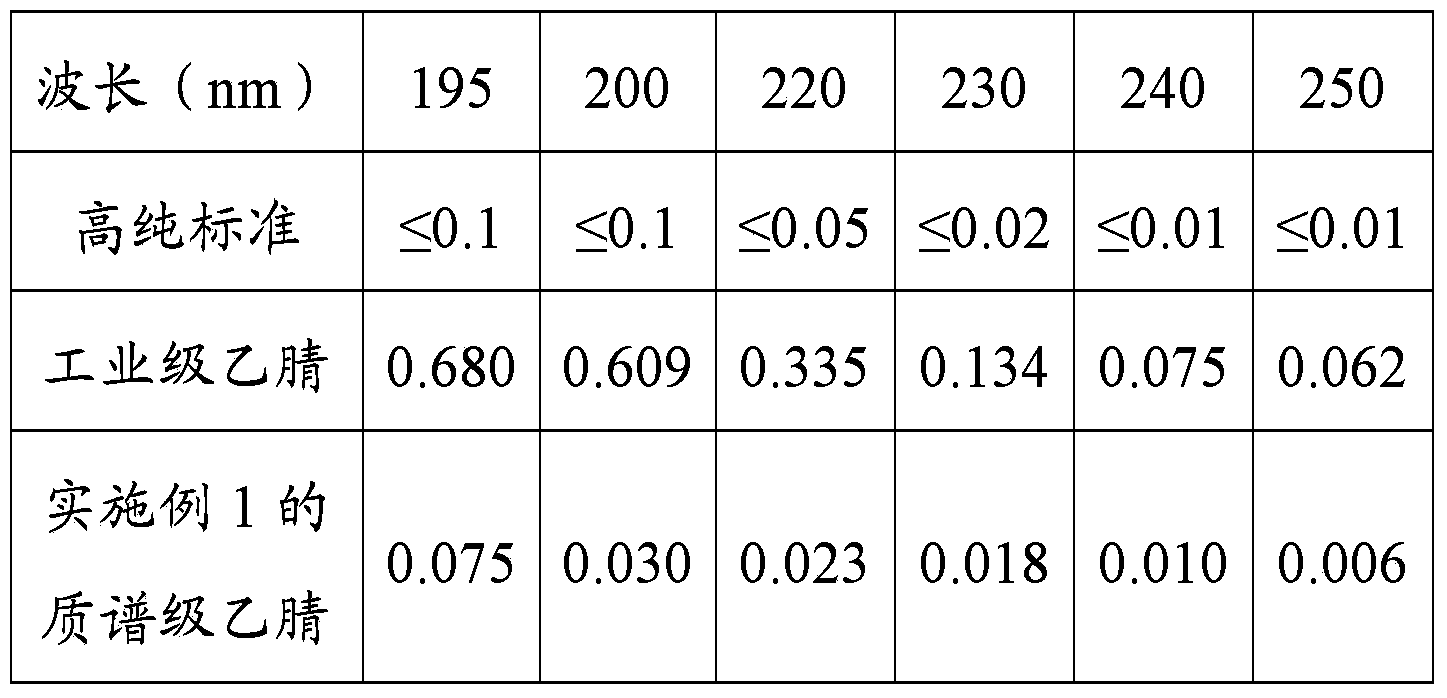

[0060] Embodiment 1 Preparation of mass spectrometry grade acetonitrile product

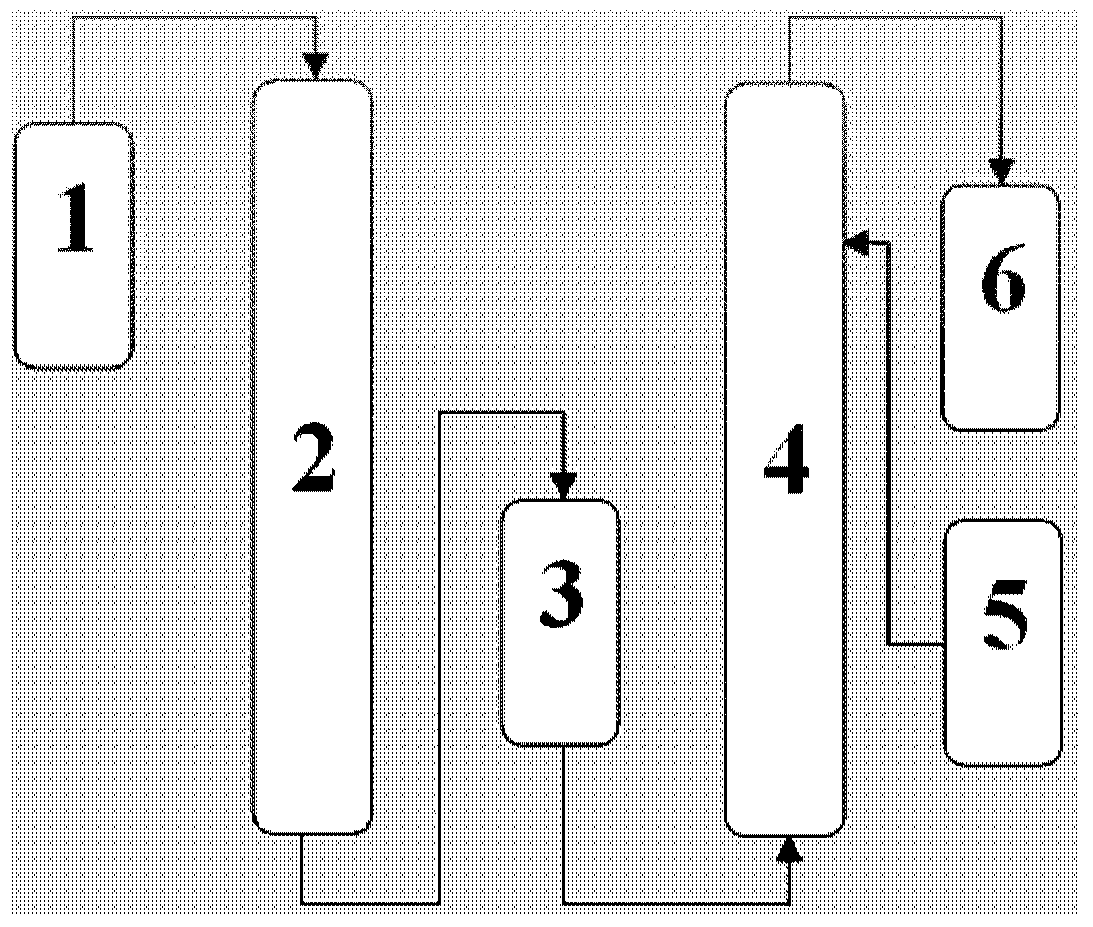

[0061] A method for preparing mass spectrometry grade acetonitrile, said mass spectrometry grade acetonitrile is obtained by preparing and purifying industrial grade acetonitrile, said method comprising three steps of adsorption, oxidation and rectification:

[0062] (1) Adsorption

[0063] With 20 liters of industrial grade acetonitrile (Nanjing Nanshi Chemical Reagent Co., Ltd.) from the chromatographic column (200 orders, Shanghai Wusi Chemical Reagent Co., Ltd.) filled with 100-200 mesh 2.5kg alumina, after the adsorbent is activated, dry In the chromatographic column, no dead volume is left, and the raw material is pumped in from the top with a metering pump, the flow rate of the raw material is controlled, and the material is received at the bottom. The height of the chromatographic column is 1.8m, and the inner diameter is 8cm; Adsorb to remove trace physical impurities and a small amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com